Upflow Anaerobic Sludge Blanket (UASB) reactors efficiently treat high-strength industrial wastewater by promoting anaerobic digestion and biogas production, reducing sludge production and operational costs. Membrane Bioreactor (MBR) systems combine biological treatment with membrane filtration, delivering superior effluent quality and compact footprint suitable for stringent discharge standards. The choice between UASB and MBR depends on wastewater characteristics, energy recovery goals, and treatment efficiency requirements.

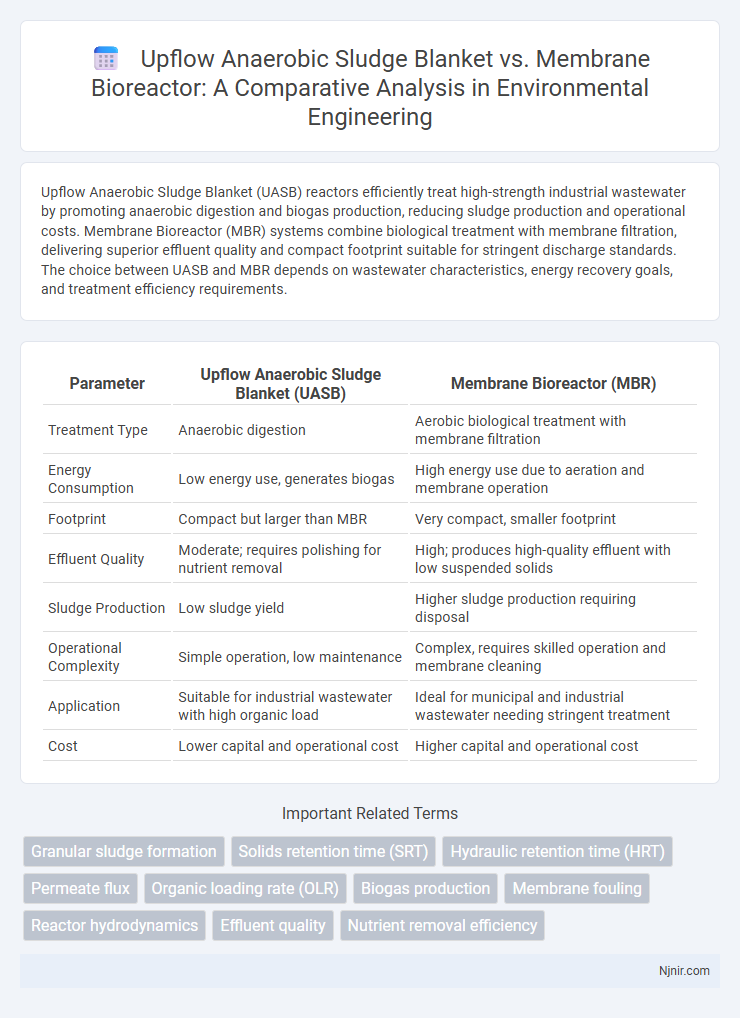

Table of Comparison

| Parameter | Upflow Anaerobic Sludge Blanket (UASB) | Membrane Bioreactor (MBR) |

|---|---|---|

| Treatment Type | Anaerobic digestion | Aerobic biological treatment with membrane filtration |

| Energy Consumption | Low energy use, generates biogas | High energy use due to aeration and membrane operation |

| Footprint | Compact but larger than MBR | Very compact, smaller footprint |

| Effluent Quality | Moderate; requires polishing for nutrient removal | High; produces high-quality effluent with low suspended solids |

| Sludge Production | Low sludge yield | Higher sludge production requiring disposal |

| Operational Complexity | Simple operation, low maintenance | Complex, requires skilled operation and membrane cleaning |

| Application | Suitable for industrial wastewater with high organic load | Ideal for municipal and industrial wastewater needing stringent treatment |

| Cost | Lower capital and operational cost | Higher capital and operational cost |

Introduction to Upflow Anaerobic Sludge Blanket and Membrane Bioreactor

Upflow Anaerobic Sludge Blanket (UASB) reactors are engineered for wastewater treatment by promoting the anaerobic digestion of organic matter through a dense sludge blanket that facilitates microbial activity and biogas production. Membrane Bioreactors (MBR) combine conventional activated sludge processes with membrane filtration, enhancing solid-liquid separation and producing high-quality effluent suitable for reuse. Both technologies offer significant advantages in terms of efficiency and footprint, with UASB excelling in energy recovery and MBR providing superior effluent quality and operational control.

Fundamental Principles of UASB and MBR Systems

The Upflow Anaerobic Sludge Blanket (UASB) system operates on the principle of anaerobic digestion, where wastewater flows upward through a sludge blanket composed of microbial granules that degrade organic matter, producing biogas as a byproduct. In contrast, Membrane Bioreactor (MBR) technology combines conventional activated sludge processes with membrane filtration, allowing for efficient solid-liquid separation and higher quality effluent. UASB is energy-efficient and suited for high-strength wastewater with low energy input, while MBR offers superior contaminant removal and compact design, ideal for complex and variable wastewater streams.

Comparative Analysis of Treatment Efficiency

Upflow Anaerobic Sludge Blanket (UASB) reactors achieve high organic matter removal efficiency, typically reaching 70-85% Chemical Oxygen Demand (COD) reduction, and excel in treating high-strength wastewater with low energy consumption. Membrane Bioreactors (MBRs) combine biological degradation with membrane filtration, offering superior effluent quality by achieving over 95% COD removal and nearly complete pathogen elimination. While UASB is cost-effective for industrial wastewater with slower microbial growth, MBR systems provide higher treatment reliability and footprint reduction, making them suitable for stringent discharge standards in municipal applications.

Energy Consumption and Operational Costs

Upflow Anaerobic Sludge Blanket (UASB) systems generally exhibit lower energy consumption compared to Membrane Bioreactors (MBRs) due to their reliance on anaerobic digestion, which produces biogas that can be used for energy recovery. Operational costs for UASB are typically reduced as they require less aeration and simpler mechanical components, whereas MBRs incur higher costs linked to membrane maintenance, replacement, and intensive aeration requirements. The choice between UASB and MBR significantly impacts overall energy efficiency and cost-effectiveness in wastewater treatment projects.

Sludge Production and Management

Upflow Anaerobic Sludge Blanket (UASB) reactors produce lower quantities of sludge due to the anaerobic digestion process, which reduces organic matter more efficiently and generates biogas as a valuable byproduct, enhancing sludge management. In contrast, Membrane Bioreactors (MBRs) typically produce higher sludge volumes with significant biomass accumulation because of aerobic microbial activity, necessitating frequent sludge wasting and advanced handling protocols. The reduced sludge yield in UASB systems lowers disposal costs and operational complexity compared to the higher management demands of MBR sludge.

Quality of Treated Effluent

Upflow Anaerobic Sludge Blanket (UASB) systems produce treated effluent with moderate biochemical oxygen demand (BOD) and suspended solids removal, typically achieving BOD5 reductions around 70-90%. Membrane Bioreactor (MBR) technology provides superior effluent quality through physical filtration and biological treatment, often reducing BOD5 and total suspended solids (TSS) to below 5 mg/L, meeting stringent discharge standards. MBRs also achieve higher pathogen removal and lower nutrient concentrations, leading to effluents suitable for water reuse applications.

Space Requirements and Infrastructure Needs

Upflow Anaerobic Sludge Blanket (UASB) systems require significantly less space due to their vertical design, making them ideal for compact installations with minimal footprint. Membrane Bioreactors (MBRs), on the other hand, demand larger infrastructure areas to accommodate membrane modules, aeration tanks, and supporting equipment. UASB's simpler infrastructure reduces construction and operational complexity compared to the more technologically intensive MBR setups.

Applicability to Wastewater Types

Upflow Anaerobic Sludge Blanket (UASB) reactors are highly effective for treating high-strength industrial wastewater rich in organic content, such as food processing and brewery effluents, due to their anaerobic digestion process that reduces sludge production and energy use. Membrane Bioreactors (MBRs) offer superior applicability for municipal and industrial wastewater with variable loads, including domestic sewage and pharmaceutical waste, providing enhanced effluent quality through advanced membrane filtration that retains biomass and contaminants. UASB systems excel in warm climates where temperature supports anaerobic microbial activity, while MBRs provide more robust performance across diverse wastewater streams and stringent discharge standards.

Environmental Impact and Sustainability

Upflow Anaerobic Sludge Blanket (UASB) systems offer significant environmental benefits by producing biogas that can be harnessed for renewable energy, reducing greenhouse gas emissions and lowering carbon footprints. Membrane Bioreactors (MBRs) provide superior effluent quality, allowing water reuse and minimizing water pollution, which supports sustainable water management practices. Both technologies contribute to circular economy goals, but UASB excels in energy recovery while MBRs enhance water resource sustainability through advanced filtration and pathogen removal.

Future Trends and Technological Innovations

Future trends in wastewater treatment highlight the integration of Upflow Anaerobic Sludge Blanket (UASB) reactors with advanced membrane technologies to enhance treatment efficiency and energy recovery. Technological innovations focus on developing hybrid systems combining UASB's high organic load capacity with Membrane Bioreactor (MBR) systems' superior effluent quality and compact footprint. Emerging research emphasizes smart monitoring using AI and IoT for real-time process optimization, making these systems more sustainable and cost-effective for large-scale municipal and industrial applications.

Granular sludge formation

Upflow Anaerobic Sludge Blanket (UASB) systems excel in granular sludge formation due to their high biomass retention and natural aggregation of anaerobic microbes, while Membrane Bioreactors (MBRs) typically rely on membrane filtration rather than granular sludge for biomass separation and retention.

Solids retention time (SRT)

Upflow Anaerobic Sludge Blanket (UASB) reactors typically exhibit longer Solids Retention Times (SRT) due to sludge granule retention, whereas Membrane Bioreactors (MBR) achieve precise SRT control through membrane filtration, enhancing biomass concentration and process stability.

Hydraulic retention time (HRT)

Upflow Anaerobic Sludge Blanket systems typically have longer Hydraulic Retention Times (HRT) ranging from 8 to 48 hours, whereas Membrane Bioreactors operate with shorter HRTs between 4 and 12 hours due to enhanced biomass retention and membrane filtration efficiency.

Permeate flux

Upflow Anaerobic Sludge Blanket systems typically achieve lower permeate flux rates compared to Membrane Bioreactors, which provide higher permeate flux due to membrane filtration technology.

Organic loading rate (OLR)

Upflow Anaerobic Sludge Blanket (UASB) systems typically achieve higher Organic Loading Rates (OLR) of 8-12 kg COD/m3/day compared to Membrane Bioreactors (MBR), which generally operate at lower OLRs around 2-4 kg COD/m3/day due to membrane filtration constraints.

Biogas production

Upflow Anaerobic Sludge Blanket (UASB) reactors typically generate higher biogas volumes with greater methane content compared to Membrane Bioreactors (MBRs), which primarily focus on effluent quality rather than biogas production.

Membrane fouling

Membrane Bioreactors experience significant membrane fouling due to the accumulation of biomass and extracellular polymeric substances, whereas Upflow Anaerobic Sludge Blanket systems face lower fouling risks because of their different sludge retention and filtration processes.

Reactor hydrodynamics

Upflow Anaerobic Sludge Blanket reactors feature vertically upward flow promoting granular sludge retention and high biomass concentration, whereas Membrane Bioreactors rely on membrane filtration for solid-liquid separation, enhancing hydraulic retention time and flow control.

Effluent quality

Upflow Anaerobic Sludge Blanket (UASB) reactors typically produce effluent with higher levels of biochemical oxygen demand (BOD) and suspended solids, whereas Membrane Bioreactors (MBRs) deliver superior effluent quality by effectively removing solids and organic contaminants to meet stringent discharge standards.

Nutrient removal efficiency

Upflow Anaerobic Sludge Blanket systems typically achieve lower nitrogen and phosphorus removal efficiencies compared to Membrane Bioreactors, which can consistently exceed 90% nutrient removal through advanced filtration and biological processes.

Upflow Anaerobic Sludge Blanket vs Membrane Bioreactor Infographic

njnir.com

njnir.com