Microalgae biofuel offers a sustainable alternative to traditional biodiesel by utilizing carbon dioxide and wastewater for growth, significantly reducing greenhouse gas emissions. Its high lipid content enables efficient biofuel production with faster growth rates compared to conventional oil crops. The scalability and lower land use requirements of microalgae biofuel production present a promising solution for meeting future renewable energy demands.

Table of Comparison

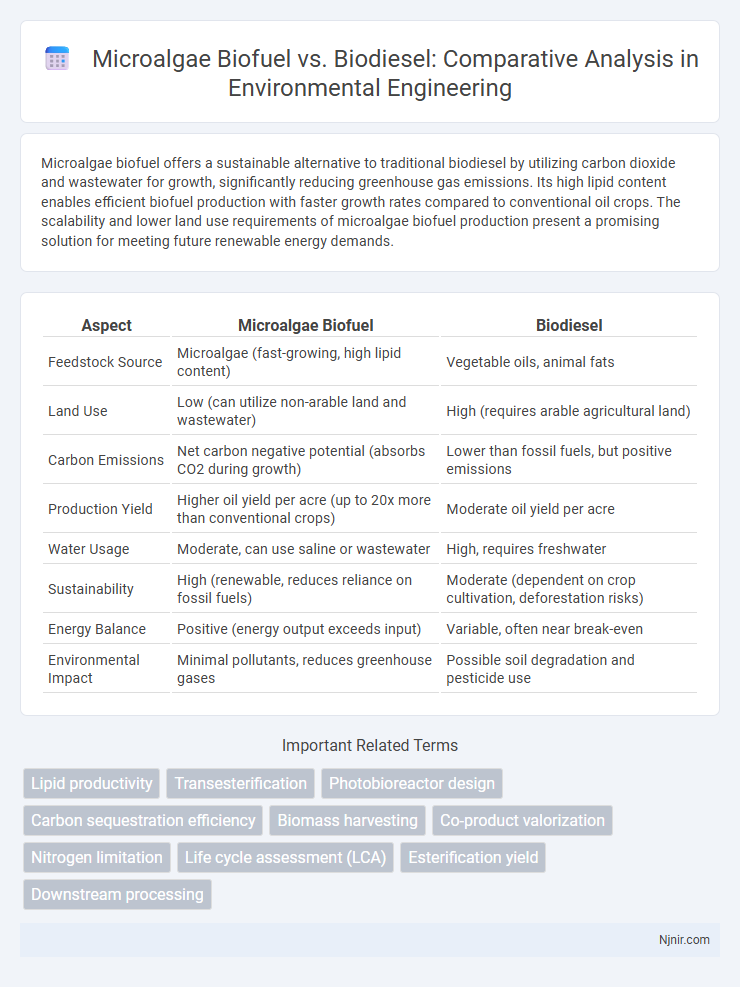

| Aspect | Microalgae Biofuel | Biodiesel |

|---|---|---|

| Feedstock Source | Microalgae (fast-growing, high lipid content) | Vegetable oils, animal fats |

| Land Use | Low (can utilize non-arable land and wastewater) | High (requires arable agricultural land) |

| Carbon Emissions | Net carbon negative potential (absorbs CO2 during growth) | Lower than fossil fuels, but positive emissions |

| Production Yield | Higher oil yield per acre (up to 20x more than conventional crops) | Moderate oil yield per acre |

| Water Usage | Moderate, can use saline or wastewater | High, requires freshwater |

| Sustainability | High (renewable, reduces reliance on fossil fuels) | Moderate (dependent on crop cultivation, deforestation risks) |

| Energy Balance | Positive (energy output exceeds input) | Variable, often near break-even |

| Environmental Impact | Minimal pollutants, reduces greenhouse gases | Possible soil degradation and pesticide use |

Introduction to Microalgae Biofuel and Biodiesel

Microalgae biofuel harnesses rapid-growing aquatic microorganisms that convert sunlight and CO2 into lipid-rich biomass, offering a sustainable and high-yield alternative to traditional fuels. Biodiesel, typically derived from vegetable oils or animal fats, undergoes transesterification to produce fatty acid methyl esters compatible with diesel engines. The superior carbon fixation efficiency and non-competition with food crops position microalgae biofuel as a promising solution to reduce greenhouse gas emissions and enhance energy security compared to conventional biodiesel sources.

Feedstock Sources: Microalgae vs. Traditional Biodiesel

Microalgae biofuel utilizes fast-growing, photosynthetic microorganisms capable of producing high lipid content, offering a sustainable and non-arable feedstock source that does not compete with food crops. Traditional biodiesel primarily relies on feedstocks like soybean, palm oil, and rapeseed, which require extensive agricultural land and water resources, often leading to deforestation and food vs. fuel conflicts. The high yield per hectare of microalgae and its ability to grow in saline or wastewater environments make it a more environmentally advantageous and scalable alternative to conventional biodiesel feedstocks.

Energy Efficiency and Yield Comparison

Microalgae biofuel demonstrates significantly higher energy efficiency and yield compared to conventional biodiesel derived from crops like soybean or palm. Microalgae can produce up to 58,700 liters of oil per hectare annually, vastly surpassing the 3,800 liters per hectare typical of traditional biodiesel sources. This superior biomass productivity and lipid content make microalgae a more sustainable and economically viable option for large-scale biofuel production.

Environmental Impact Assessment

Microalgae biofuel demonstrates a significantly lower carbon footprint compared to conventional biodiesel due to its higher photosynthetic efficiency and rapid biomass growth, which enable greater CO2 sequestration. Life cycle assessments reveal microalgae biofuel produces less greenhouse gas emissions and requires less land use, reducing deforestation and biodiversity loss often linked with crop-based biodiesel. However, energy inputs for cultivation and harvesting remain critical factors that influence the overall environmental impact of microalgae biofuel production.

Life Cycle Analysis of Microalgae Biofuel and Biodiesel

Life Cycle Analysis (LCA) of microalgae biofuel reveals significantly lower greenhouse gas emissions compared to conventional biodiesel derived from crops such as soybean or palm oil, primarily due to higher carbon capture during algae growth and reduced land use impact. Microalgae biofuel LCA also accounts for energy inputs in cultivation, harvesting, and processing, which remain a challenge but are rapidly improving with advances in photobioreactor efficiency and lipid extraction technologies. Biodiesel LCA typically highlights issues like fertilizer use and land degradation, whereas microalgae biofuel offers potential for wastewater treatment integration and CO2 sequestration, making it a more sustainable alternative over the full production and consumption lifecycle.

Greenhouse Gas Emissions and Carbon Footprint

Microalgae biofuel exhibits significantly lower greenhouse gas emissions and a smaller carbon footprint compared to conventional biodiesel derived from crops like soybean or palm oil. The rapid growth rate and high photosynthetic efficiency of microalgae enable more efficient CO2 sequestration, reducing net atmospheric carbon. Lifecycle analyses reveal that microalgae biofuels can lower GHG emissions by up to 60-80% relative to fossil diesel, making them a more sustainable alternative for energy production.

Water and Land Use Requirements

Microalgae biofuel requires significantly less land compared to traditional biodiesel, as microalgae can be cultivated in compact bioreactors or non-arable land, minimizing competition with food crops. Water use in microalgae cultivation can be optimized through recycling systems and utilization of wastewater, offering a more sustainable solution than biodiesel feedstocks like soy or palm oil, which demand extensive freshwater irrigation. This efficiency in water and land use positions microalgae biofuel as a more environmentally viable alternative in renewable energy production.

Technological Challenges and Innovations

Microalgae biofuel production faces significant technological challenges such as high cultivation costs, energy-intensive harvesting, and complex conversion processes compared to conventional biodiesel derived from vegetable oils or animal fats. Innovations like genetic engineering of microalgae strains, advancements in photobioreactor design, and integrated biorefinery approaches enhance lipid yield and reduce energy consumption during extraction. Emerging technologies including enzymatic transesterification and carbon dioxide capture integration aim to improve the sustainability and economic viability of microalgae-based biofuels compared to traditional biodiesel.

Economic Viability and Scalability

Microalgae biofuel offers higher energy yield per acre compared to traditional biodiesel feedstocks, driving economic viability through increased productivity and reduced land use. Despite higher initial capital costs and technological challenges, advances in cultivation and harvesting techniques are improving scalability and reducing production expenses. Government incentives and investments in microalgae biorefineries further enhance the economic potential and market competitiveness against conventional biodiesel.

Future Prospects and Sustainability

Microalgae biofuel offers significant future prospects due to its rapid growth rates, high lipid content, and ability to thrive on non-arable land, making it a sustainable alternative to traditional biodiesel derived from crops like soybean or palm. Its potential for carbon dioxide mitigation and lower water usage enhances environmental benefits, aligning with global sustainability goals. Advances in genetic engineering and bioreactor technology are expected to improve yield efficiency and cost-effectiveness, positioning microalgae biofuel as a scalable and eco-friendly energy source.

Lipid productivity

Microalgae biofuel exhibits significantly higher lipid productivity, reaching up to 200 mg/L/day, compared to conventional biodiesel sources, enhancing sustainable energy yield and efficiency.

Transesterification

Transesterification efficiency in microalgae biofuel production surpasses traditional biodiesel methods due to higher lipid yields and faster reaction rates.

Photobioreactor design

Photobioreactor design enhances microalgae biofuel production efficiency by optimizing light exposure and nutrient distribution, offering a sustainable alternative to traditional biodiesel with higher carbon capture and energy yield.

Carbon sequestration efficiency

Microalgae biofuel exhibits significantly higher carbon sequestration efficiency than conventional biodiesel by capturing more CO2 per unit of fuel produced through rapid biomass growth and photosynthesis.

Biomass harvesting

Microalgae biofuel offers higher biomass harvesting efficiency than conventional biodiesel feedstocks due to rapid growth rates and easier cell density concentration methods.

Co-product valorization

Microalgae biofuel production enables higher co-product valorization through valuable compounds like proteins, pigments, and bioplastics, offering greater economic and environmental benefits compared to traditional biodiesel.

Nitrogen limitation

Nitrogen limitation in microalgae cultivation enhances lipid accumulation, making microalgae biofuel a more sustainable and higher-yield alternative to traditional biodiesel derived from crop oils.

Life cycle assessment (LCA)

Life cycle assessment (LCA) reveals microalgae biofuel offers higher carbon sequestration and renewable energy potential with lower greenhouse gas emissions compared to traditional biodiesel derived from terrestrial crops.

Esterification yield

Microalgae biofuel exhibits higher esterification yield compared to traditional biodiesel due to its superior lipid content and efficient conversion process.

Downstream processing

Microalgae biofuel downstream processing requires complex and energy-intensive steps like harvesting, cell disruption, and lipid extraction compared to the simpler, solvent-based processing used in traditional biodiesel production.

microalgae biofuel vs biodiesel Infographic

njnir.com

njnir.com