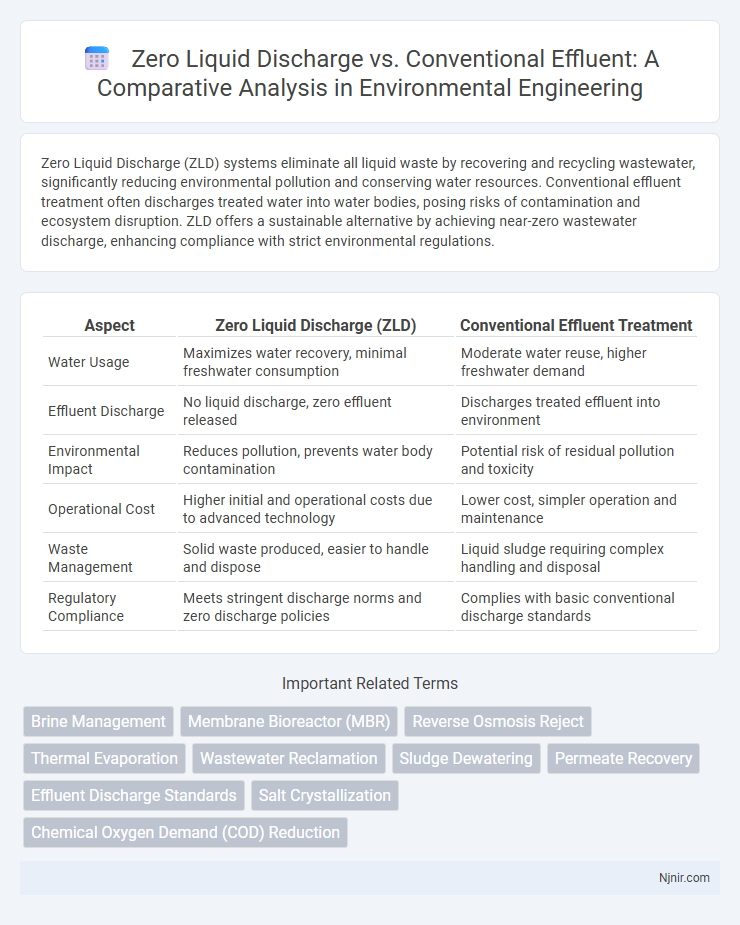

Zero Liquid Discharge (ZLD) systems eliminate all liquid waste by recovering and recycling wastewater, significantly reducing environmental pollution and conserving water resources. Conventional effluent treatment often discharges treated water into water bodies, posing risks of contamination and ecosystem disruption. ZLD offers a sustainable alternative by achieving near-zero wastewater discharge, enhancing compliance with strict environmental regulations.

Table of Comparison

| Aspect | Zero Liquid Discharge (ZLD) | Conventional Effluent Treatment |

|---|---|---|

| Water Usage | Maximizes water recovery, minimal freshwater consumption | Moderate water reuse, higher freshwater demand |

| Effluent Discharge | No liquid discharge, zero effluent released | Discharges treated effluent into environment |

| Environmental Impact | Reduces pollution, prevents water body contamination | Potential risk of residual pollution and toxicity |

| Operational Cost | Higher initial and operational costs due to advanced technology | Lower cost, simpler operation and maintenance |

| Waste Management | Solid waste produced, easier to handle and dispose | Liquid sludge requiring complex handling and disposal |

| Regulatory Compliance | Meets stringent discharge norms and zero discharge policies | Complies with basic conventional discharge standards |

Introduction to Wastewater Management Strategies

Zero Liquid Discharge (ZLD) and Conventional Effluent treatment represent two distinct wastewater management strategies aimed at minimizing environmental impact. ZLD systems achieve near-complete water recycling by recovering all wastewater components, generating solid waste for disposal, and eliminating liquid discharge, thereby promoting water conservation and compliance with stringent environmental regulations. Conventional Effluent treatment typically involves primary, secondary, and tertiary processes to reduce pollutants before discharging treated water into natural bodies, posing a risk of residual contaminants affecting ecosystems.

Overview of Zero Liquid Discharge (ZLD) Systems

Zero Liquid Discharge (ZLD) systems are advanced wastewater treatment technologies designed to eliminate liquid waste by recovering and recycling all effluent components. Unlike conventional effluent treatment, which discharges partially treated water into the environment, ZLD processes use stages such as ultrafiltration, reverse osmosis, evaporators, and crystallizers to achieve near 100% water recovery and minimize environmental impact. These systems are integral in industries with stringent discharge regulations or water scarcity, ensuring zero water loss and compliance with sustainability goals.

Conventional Effluent Treatment Methods

Conventional effluent treatment methods primarily involve primary, secondary, and tertiary treatment processes designed to remove solids, organic matter, and nutrients from wastewater before discharge. Common techniques include sedimentation, activated sludge processes, biofiltration, and chemical coagulation to reduce pollutants to permissible levels. These methods often result in treated effluent discharge with residual contaminants and liquid waste, unlike Zero Liquid Discharge systems that aim to eliminate liquid discharge entirely.

Comparative Analysis: ZLD vs. Conventional Effluent Systems

Zero Liquid Discharge (ZLD) systems achieve near-complete recovery of wastewater by eliminating liquid discharge and converting all effluent into reusable water and solid waste, significantly reducing environmental pollution compared to conventional effluent systems that often release partially treated effluents into water bodies. ZLD technology incorporates advanced treatment steps such as reverse osmosis, evaporators, and crystallizers, which result in higher operational costs but ensure compliance with stringent discharge regulations and promote water conservation. Conventional effluent systems prioritize cost-effectiveness and simpler treatment processes but face challenges like increased risk of contaminant release, limited resource recovery, and vulnerability to regulatory non-compliance.

Key Technologies in Zero Liquid Discharge

Zero Liquid Discharge (ZLD) systems integrate advanced membrane technologies such as reverse osmosis and electrodialysis with thermal methods like multi-effect evaporation and crystallization to achieve near-complete water recovery. These key technologies enable ZLD to treat and recycle industrial effluents more efficiently than conventional methods, which primarily rely on biological treatments and simple filtration, often resulting in liquid waste discharge. The combination of membrane filtration and thermal concentration in ZLD minimizes environmental impact by eliminating effluent discharge and recovering valuable salts and water for reuse.

Environmental Impacts of ZLD and Conventional Effluent

Zero Liquid Discharge (ZLD) systems eliminate all liquid waste from industrial processes, significantly reducing water pollution by preventing the discharge of untreated or partially treated effluent into natural water bodies. Conventional effluent treatment often releases treated wastewater containing residual pollutants, contributing to oxygen depletion, eutrophication, and harm to aquatic ecosystems. The environmental impact of ZLD is substantially lower, as it promotes water reuse and minimizes contamination, conserving freshwater resources and protecting biodiversity.

Economic Considerations and Cost Analysis

Zero Liquid Discharge (ZLD) systems, while capital-intensive due to advanced treatment technologies such as evaporation and crystallization, offer long-term economic benefits by minimizing wastewater disposal costs and enabling resource recovery from saline brine. Conventional effluent treatment typically requires lower initial investment but incurs recurring expenses linked to effluent discharge fees, environmental compliance penalties, and potential groundwater contamination remediation. Cost analysis reveals that ZLD is economically advantageous for industries facing stringent discharge regulations or high water scarcity, as it reduces dependence on freshwater and mitigates costly environmental liabilities over time.

Regulatory Compliance and Industry Standards

Zero Liquid Discharge (ZLD) systems achieve superior regulatory compliance by eliminating liquid waste discharge, significantly reducing environmental pollution and meeting stringent effluent standards set by agencies such as the EPA and EU Water Framework Directive. Conventional effluent treatment typically involves secondary or tertiary processes that may fail to meet tightening discharge limits, leading to regulatory risks and potential fines. Industries adopting ZLD benefit from enhanced resource recovery, reduced water consumption, and alignment with ISO 14001 environmental management standards.

Challenges in Implementing ZLD Solutions

Implementing Zero Liquid Discharge (ZLD) systems presents significant challenges due to high capital and operational costs, complex infrastructure, and energy-intensive processes compared to conventional effluent treatment. ZLD requires advanced technologies like evaporation and crystallization, which demand continuous monitoring and skilled operation to ensure compliance with stringent environmental regulations. Limited scalability and potential issues with salt disposal further complicate widespread adoption of ZLD solutions in various industrial sectors.

Future Trends in Wastewater Treatment Technologies

Zero Liquid Discharge (ZLD) technology is gaining traction over conventional effluent treatment due to its ability to eliminate liquid waste by recovering valuable resources and minimizing environmental impact. Future trends emphasize integrating advanced membrane filtration, evaporation, and crystallization processes combined with AI-driven monitoring systems to enhance efficiency and reduce operational costs. Sustainable wastewater treatment will increasingly rely on ZLD systems to meet stringent regulatory standards and support circular economy initiatives.

Brine Management

Zero Liquid Discharge systems achieve superior brine management by completely eliminating wastewater discharge, whereas conventional effluent treatment relies on partial brine reduction and disposal.

Membrane Bioreactor (MBR)

Zero Liquid Discharge (ZLD) systems using Membrane Bioreactor (MBR) technology achieve higher water recovery and lower environmental impact by completely recycling wastewater compared to Conventional Effluent Treatment, which typically discharges treated water with residual pollutants.

Reverse Osmosis Reject

Zero Liquid Discharge systems minimize environmental impact by fully recycling Reverse Osmosis reject brine, unlike Conventional Effluent treatment which discharges concentrated waste streams.

Thermal Evaporation

Thermal evaporation in Zero Liquid Discharge systems eliminates wastewater by converting effluent into solid residues and clean water vapor, significantly reducing environmental impact compared to conventional effluent treatment methods.

Wastewater Reclamation

Zero Liquid Discharge (ZLD) achieves superior wastewater reclamation by completely eliminating liquid waste through advanced treatment and recovery processes, whereas conventional effluent systems typically discharge treated water with residual contaminants.

Sludge Dewatering

Zero Liquid Discharge systems minimize sludge volume through enhanced dewatering techniques compared to conventional effluent treatment, resulting in reduced disposal costs and improved resource recovery.

Permeate Recovery

Zero Liquid Discharge systems achieve near 100% permeate recovery by recycling all treated water, whereas conventional effluent treatment typically recovers only 70-85%, resulting in significant liquid waste discharge.

Effluent Discharge Standards

Zero Liquid Discharge (ZLD) systems achieve effluent discharge standards by eliminating liquid waste through advanced treatment and recovery processes, whereas conventional effluent treatment often results in discharge that meets minimum regulatory limits but may still contain pollutants.

Salt Crystallization

Zero Liquid Discharge systems achieve superior salt crystallization compared to conventional effluent treatment by eliminating liquid waste and recovering salts as solid crystals for reuse or safe disposal.

Chemical Oxygen Demand (COD) Reduction

Zero Liquid Discharge systems achieve up to 99% Chemical Oxygen Demand (COD) reduction by recycling wastewater and eliminating effluent discharge, whereas conventional effluent treatment typically reduces COD by only 70-85% before releasing treated water.

Zero Liquid Discharge vs Conventional Effluent Infographic

njnir.com

njnir.com