Membrane bioreactors (MBRs) enhance wastewater treatment by combining biological degradation with membrane filtration, resulting in higher effluent quality and a smaller footprint than conventional activated sludge systems. The use of fine membranes in MBRs effectively removes suspended solids and pathogens, reducing the need for secondary clarifiers and improving sustainability. Operational flexibility and improved sludge retention time in MBRs lead to more efficient nutrient removal and lower sludge production compared to traditional activated sludge processes.

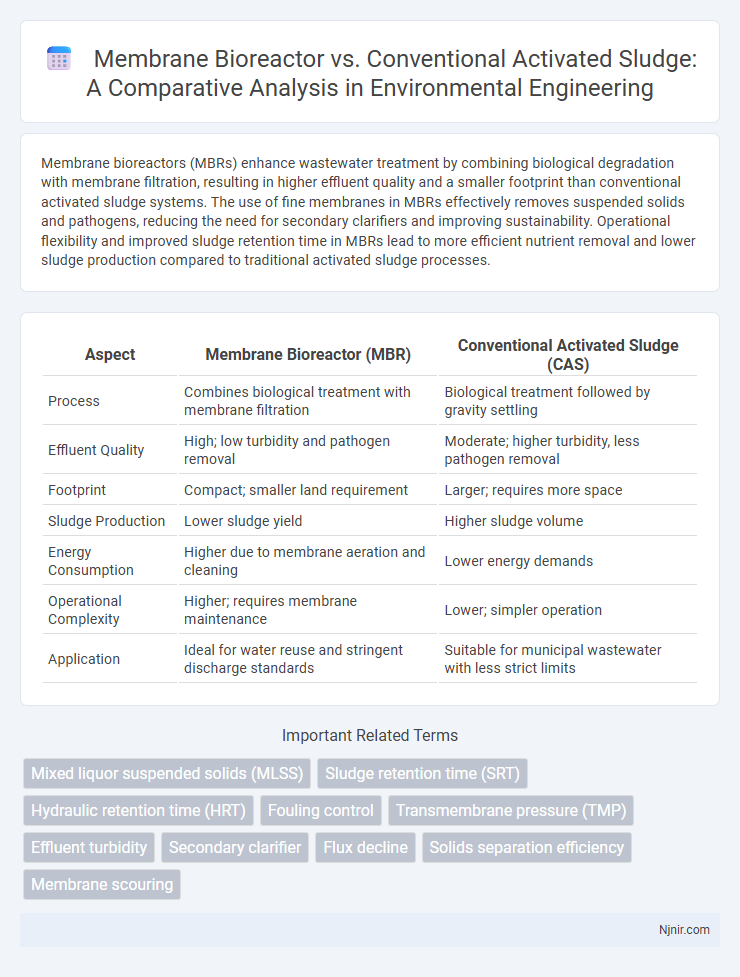

Table of Comparison

| Aspect | Membrane Bioreactor (MBR) | Conventional Activated Sludge (CAS) |

|---|---|---|

| Process | Combines biological treatment with membrane filtration | Biological treatment followed by gravity settling |

| Effluent Quality | High; low turbidity and pathogen removal | Moderate; higher turbidity, less pathogen removal |

| Footprint | Compact; smaller land requirement | Larger; requires more space |

| Sludge Production | Lower sludge yield | Higher sludge volume |

| Energy Consumption | Higher due to membrane aeration and cleaning | Lower energy demands |

| Operational Complexity | Higher; requires membrane maintenance | Lower; simpler operation |

| Application | Ideal for water reuse and stringent discharge standards | Suitable for municipal wastewater with less strict limits |

Overview of Membrane Bioreactor (MBR) and Conventional Activated Sludge (CAS) Systems

Membrane Bioreactor (MBR) systems combine activated sludge treatment with membrane filtration, enhancing solid-liquid separation and producing higher quality effluent with less sludge production compared to Conventional Activated Sludge (CAS) systems. CAS relies on gravity-based settling tanks for biomass separation, often resulting in larger footprint and less effective removal of suspended solids and pathogens. MBR technology offers superior operational flexibility, better effluent quality, and reduced environmental impact due to its compact design and advanced filtration membranes.

Fundamental Principles of MBR and CAS Technologies

Membrane bioreactors (MBR) combine activated sludge biological treatment with membrane filtration, allowing for higher biomass concentration and superior solid-liquid separation compared to conventional activated sludge (CAS) systems that rely on gravity settling of sludge. MBR systems utilize microfiltration or ultrafiltration membranes to retain microorganisms and suspended solids, enabling smaller footprint and better effluent quality with reduced sludge production. CAS technology depends on aeration and sedimentation tanks for organic matter degradation and sludge settling, which often leads to lower sludge retention times and potential issues with sludge bulking or insufficient solids separation.

Process Flow and Design Comparison

Membrane bioreactors (MBRs) integrate membrane filtration with activated sludge processes, replacing secondary clarifiers to provide enhanced solid-liquid separation and higher biomass concentrations. Conventional activated sludge (CAS) systems rely on gravity settling in secondary clarifiers, requiring larger footprints and often producing less effluent quality compared to MBRs. MBR design optimizes reactor volume by maintaining mixed liquor suspended solids (MLSS) concentrations typically between 8,000-12,000 mg/L, whereas CAS systems operate at lower MLSS levels around 2,500-4,000 mg/L, influencing aeration energy and hydraulic retention times.

Treatment Efficiency: BOD, COD, and Nutrient Removal

Membrane bioreactors (MBRs) achieve superior treatment efficiency compared to conventional activated sludge (CAS) systems by consistently removing 95-99% of biochemical oxygen demand (BOD) and chemical oxygen demand (COD), while CAS typically achieves 85-90% removal. MBRs excel in nutrient removal, particularly nitrogen and phosphorus, due to enhanced biomass concentration and extended sludge retention times, resulting in total nitrogen removal rates exceeding 70-80%, compared to 50-60% in CAS. The membrane filtration process in MBRs also ensures near-complete retention of suspended solids and microorganisms, leading to significantly improved effluent quality and reduced environmental impact.

Footprint and Space Requirements

Membrane bioreactor (MBR) systems typically require a significantly smaller footprint compared to conventional activated sludge (CAS) processes due to the integration of membrane filtration and biological treatment in a compact unit. MBRs enable higher mixed liquor suspended solids (MLSS) concentrations, reducing the volume of the bioreactor and eliminating the need for secondary clarifiers, resulting in space savings of up to 50-70%. This compact design makes MBRs especially suitable for urban or industrial applications where land availability is limited.

Sludge Production and Management

Membrane bioreactors (MBRs) significantly reduce sludge production compared to conventional activated sludge (CAS) systems by enhancing biomass retention and promoting higher microbial concentration. MBRs yield more concentrated, denser sludge with lower volume, simplifying sludge handling and reducing disposal costs. Conventional activated sludge generates larger sludge volumes with lower solids concentrations, requiring more frequent and complex sludge management processes.

Energy Consumption and Operational Costs

Membrane bioreactors (MBRs) generally consume more energy than conventional activated sludge (CAS) systems due to membrane aeration and filtration processes, with MBR energy use ranging from 0.6 to 1.2 kWh/m3 compared to CAS's 0.3 to 0.6 kWh/m3. Operational costs for MBRs are higher primarily because of membrane maintenance, replacement costs, and the need for specialized equipment, whereas CAS systems benefit from lower capital and operational expenditures. Energy efficiency improvements and longer membrane lifespans are critical factors that could reduce MBR operational costs in future wastewater treatment implementations.

Membrane Fouling Challenges vs. Settling Issues

Membrane bioreactors (MBRs) face significant challenges related to membrane fouling, which includes the accumulation of solids, biofilms, and extracellular polymeric substances that reduce permeability and increase operational costs. In contrast, conventional activated sludge systems primarily struggle with settling issues, such as sludge bulking and poor flocculation, leading to inefficient solid-liquid separation and potential effluent quality deterioration. Managing membrane fouling requires advanced cleaning protocols and membrane material innovations, while resolving settling problems often involves optimizing sludge retention time and chemical dosing strategies.

Application Suitability and Flexibility

Membrane bioreactors (MBRs) provide superior application suitability for wastewater treatment due to their ability to produce high-quality effluent suitable for reuse, making them ideal for applications requiring stringent discharge standards like industrial and municipal water reclamation. The compact design and modular nature of MBRs offer enhanced flexibility in plant expansion and operation under varying load conditions, outperforming conventional activated sludge (CAS) systems which require larger footprints and are less adaptable to fluctuating influent characteristics. MBR technology excels in scenarios demanding higher mixed liquor suspended solids (MLSS) concentrations and improved solids separation, whereas CAS systems remain cost-effective and simpler for large-scale, less stringent treatment needs.

Environmental Impact and Sustainability Assessment

Membrane bioreactors (MBRs) significantly reduce environmental impact by producing higher-quality effluent with lower suspended solids and pathogens than conventional activated sludge (CAS) systems, facilitating safer water reuse. MBRs require less footprint and enable better nutrient removal, contributing to enhanced sustainability through reduced sludge production and energy-efficient operation. While MBRs often have higher upfront costs, their long-term benefits include lower greenhouse gas emissions and minimized freshwater resource depletion compared to traditional CAS processes.

Mixed liquor suspended solids (MLSS)

Membrane bioreactors achieve higher Mixed Liquor Suspended Solids (MLSS) concentrations, typically up to 15,000 mg/L, compared to conventional activated sludge systems which usually operate around 2,000-4,000 mg/L, enabling improved biomass retention and treatment efficiency.

Sludge retention time (SRT)

Membrane bioreactors (MBRs) achieve higher sludge retention times (SRT) than conventional activated sludge systems by using membrane filtration for biomass separation, enhancing treatment efficiency and biomass concentration.

Hydraulic retention time (HRT)

Membrane bioreactors typically achieve a shorter hydraulic retention time (HRT) compared to conventional activated sludge systems due to their enhanced solid-liquid separation efficiency and higher biomass concentration.

Fouling control

Membrane bioreactors offer superior fouling control compared to conventional activated sludge systems by using fine membranes that effectively separate solids and reduce biomass washout, enhancing filtration and minimizing clogging.

Transmembrane pressure (TMP)

Membrane bioreactors maintain higher transmembrane pressure (TMP) levels than conventional activated sludge systems due to membrane fouling, necessitating frequent cleaning to ensure optimal filtration performance.

Effluent turbidity

Membrane bioreactors consistently achieve effluent turbidity levels below 1 NTU, significantly outperforming conventional activated sludge systems that typically produce turbidity ranging from 5 to 15 NTU.

Secondary clarifier

Membrane bioreactors eliminate the need for a secondary clarifier by integrating membrane filtration, improving effluent quality and reducing footprint compared to conventional activated sludge systems that rely on secondary clarifiers for solid-liquid separation.

Flux decline

Membrane bioreactors exhibit slower flux decline compared to conventional activated sludge systems due to enhanced solid-liquid separation and reduced fouling, improving operational stability and treatment efficiency.

Solids separation efficiency

Membrane bioreactors achieve superior solids separation efficiency compared to conventional activated sludge systems by utilizing advanced membrane filtration that captures finer particles and ensures higher biomass retention.

Membrane scouring

Membrane scouring in membrane bioreactors enhances filtration efficiency and reduces fouling compared to conventional activated sludge systems by continuously removing solids from membrane surfaces.

membrane bioreactor vs conventional activated sludge Infographic

njnir.com

njnir.com