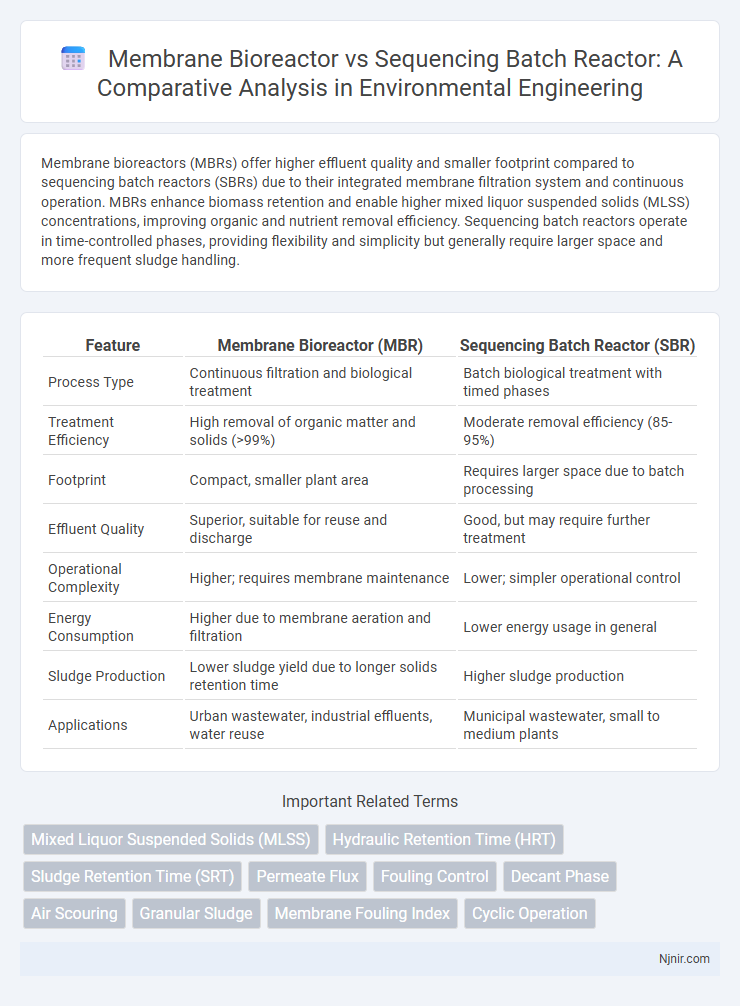

Membrane bioreactors (MBRs) offer higher effluent quality and smaller footprint compared to sequencing batch reactors (SBRs) due to their integrated membrane filtration system and continuous operation. MBRs enhance biomass retention and enable higher mixed liquor suspended solids (MLSS) concentrations, improving organic and nutrient removal efficiency. Sequencing batch reactors operate in time-controlled phases, providing flexibility and simplicity but generally require larger space and more frequent sludge handling.

Table of Comparison

| Feature | Membrane Bioreactor (MBR) | Sequencing Batch Reactor (SBR) |

|---|---|---|

| Process Type | Continuous filtration and biological treatment | Batch biological treatment with timed phases |

| Treatment Efficiency | High removal of organic matter and solids (>99%) | Moderate removal efficiency (85-95%) |

| Footprint | Compact, smaller plant area | Requires larger space due to batch processing |

| Effluent Quality | Superior, suitable for reuse and discharge | Good, but may require further treatment |

| Operational Complexity | Higher; requires membrane maintenance | Lower; simpler operational control |

| Energy Consumption | Higher due to membrane aeration and filtration | Lower energy usage in general |

| Sludge Production | Lower sludge yield due to longer solids retention time | Higher sludge production |

| Applications | Urban wastewater, industrial effluents, water reuse | Municipal wastewater, small to medium plants |

Introduction to Membrane Bioreactor (MBR) and Sequencing Batch Reactor (SBR) Technologies

Membrane Bioreactor (MBR) technology integrates activated sludge treatment with membrane filtration, enabling higher biomass concentration and superior effluent quality by effectively separating solids and microorganisms. Sequencing Batch Reactor (SBR) operates in time-sequenced phases, combining aeration and sedimentation in a single tank, allowing for flexible treatment cycles and efficient nutrient removal. Both technologies are pivotal in wastewater treatment, with MBR excelling in space-saving and effluent clarity, while SBR offers adaptability and operational simplicity.

Principles of Operation: MBR vs SBR

Membrane Bioreactors (MBRs) operate by combining conventional activated sludge treatment with membrane filtration, enabling solid-liquid separation through microfiltration or ultrafiltration membranes, which results in high-quality effluent and compact system footprint. Sequencing Batch Reactors (SBRs) function through time-sequenced phases including fill, react, settle, decant, and idle, allowing for controlled biological treatment and sedimentation in a single tank without continuous flow. MBRs maintain biomass retention and high mixed liquor suspended solids (MLSS) concentrations, while SBRs rely on gravity settling for biomass separation, influencing sludge age and treatment efficiency.

Comparative Treatment Efficiency: MBR and SBR

Membrane Bioreactors (MBRs) demonstrate higher treatment efficiency than Sequencing Batch Reactors (SBRs) due to their combination of activated sludge processes with membrane filtration, achieving superior solid-liquid separation and higher biomass concentrations. MBRs produce higher quality effluent with lower biochemical oxygen demand (BOD), total suspended solids (TSS), and pathogens, enabling more effective nutrient removal, particularly nitrogen and phosphorus. SBRs offer flexible operation and lower capital costs but generally exhibit lower effluent quality and reduced biomass retention compared to MBR systems.

Footprint and Space Requirements

Membrane bioreactors (MBRs) have a significantly smaller footprint compared to sequencing batch reactors (SBRs) due to their ability to combine biological treatment and membrane filtration within a single compact unit, allowing higher biomass concentration and enhanced treatment efficiency. SBRs require larger tanks and more space for sequential filling, reacting, settling, and decanting phases, which increases the overall footprint. MBRs are ideal for facilities with limited land availability, offering up to 50-70% space savings compared to conventional SBR systems.

Sludge Characteristics and Management

Membrane bioreactors (MBRs) produce higher quality sludge with lower solid retention times and reduced sludge volume, enhancing management efficiency and minimizing disposal costs. Sequencing batch reactors (SBRs) generate sludge with higher organic content and variable settling properties, requiring more frequent handling and careful control to prevent bulking or foaming issues. MBR systems offer superior sludge dewatering and stability, while SBRs demand more operational oversight to maintain optimal sludge characteristics.

Energy Consumption and Operational Costs

Membrane bioreactors (MBRs) typically have higher energy consumption due to aeration needs and membrane fouling control compared to sequencing batch reactors (SBRs), which operate in cyclic phases requiring less continuous aeration. Operational costs in MBRs are driven by membrane replacement, maintenance, and energy-intensive filtration, whereas SBRs benefit from lower maintenance and simpler mechanical systems, reducing overall expenses. Choosing between MBR and SBR depends on treatment capacity and water quality goals, as MBRs offer superior effluent quality at a higher operational cost.

Effluent Quality and Regulatory Compliance

Membrane bioreactors (MBRs) achieve superior effluent quality by combining microfiltration or ultrafiltration membranes with biological treatment, effectively removing suspended solids and pathogens to meet stringent regulatory standards. Sequencing batch reactors (SBRs), while flexible and effective for nutrient removal, often produce effluent with higher turbidity and require additional polishing steps to comply with strict discharge regulations. MBR technology consistently delivers lower biochemical oxygen demand (BOD), total suspended solids (TSS), and nitrogen levels, ensuring better regulatory compliance in wastewater treatment applications.

Flexibility and Scalability of Systems

Membrane bioreactors (MBRs) offer superior flexibility and scalability through modular designs that allow easy capacity expansion and integration into various wastewater treatment processes. Sequencing batch reactors (SBRs) provide operational flexibility via batch processing cycles adaptable to fluctuating influent loads but may face challenges in scaling up due to longer cycle times and footprint requirements. MBR systems typically achieve higher treatment efficiency in compact spaces, making them more suitable for scalable applications in urban and industrial settings.

Challenges and Limitations of MBR and SBR

Membrane bioreactors (MBRs) face challenges such as membrane fouling, which leads to increased operational costs and frequent maintenance requirements, limiting their long-term efficiency. Sequencing batch reactors (SBRs) encounter limitations in handling variable influent loads and require complex control systems to maintain treatment performance, often resulting in longer cycle times. Both technologies must address energy consumption concerns and sludge management issues to optimize overall wastewater treatment processes.

Future Trends and Innovations in Wastewater Treatment Technologies

Membrane bioreactors (MBRs) demonstrate advancing integration with smart sensors and AI-driven process control to enhance effluent quality and operational efficiency, while reducing energy consumption. Sequencing batch reactors (SBRs) are evolving toward hybrid configurations incorporating anammox processes and bioaugmentation techniques to improve nitrogen removal and sludge reduction. Future innovations emphasize sustainability, real-time monitoring, and automation to meet stricter discharge regulations and optimize resource recovery in wastewater treatment.

Mixed Liquor Suspended Solids (MLSS)

Membrane bioreactors (MBRs) typically sustain higher Mixed Liquor Suspended Solids (MLSS) concentrations, often exceeding 10,000 mg/L, compared to sequencing batch reactors (SBRs) which generally maintain MLSS levels around 3,000 to 5,000 mg/L, enhancing biomass retention and treatment efficiency.

Hydraulic Retention Time (HRT)

Membrane bioreactors typically have longer Hydraulic Retention Times (HRT) ranging from 6 to 12 hours compared to sequencing batch reactors, which usually operate with HRTs of 4 to 8 hours, enhancing treatment efficiency and biomass retention.

Sludge Retention Time (SRT)

Membrane bioreactors (MBRs) achieve higher Sludge Retention Time (SRT) compared to sequencing batch reactors (SBRs) due to membrane filtration allowing complete biomass retention and enhanced treatment efficiency.

Permeate Flux

Membrane bioreactors (MBRs) typically achieve higher permeate flux rates, ranging from 10 to 40 LMH (liters per square meter per hour), compared to sequencing batch reactors (SBRs), which usually rely on gravity-driven or low-pressure filtration resulting in significantly lower permeate flux.

Fouling Control

Membrane bioreactors (MBRs) achieve superior fouling control compared to sequencing batch reactors (SBRs) due to their integrated membrane filtration system enabling consistent biomass retention and reduced sludge production.

Decant Phase

The Decant Phase in sequencing batch reactors involves controlled wastewater removal to prevent solids loss, whereas membrane bioreactors eliminate the decant phase by using membranes for continuous solid-liquid separation.

Air Scouring

Membrane bioreactors utilize air scouring to effectively prevent membrane fouling by continuously dislodging particles, whereas sequencing batch reactors rely less on air scouring and more on periodic aeration cycles for microbial activity and mixing.

Granular Sludge

Granular sludge in sequencing batch reactors enhances biomass retention and substrate degradation, while membrane bioreactors provide superior filtration and effluent quality through membrane separation technology.

Membrane Fouling Index

Membrane bioreactors exhibit a lower Membrane Fouling Index (MFI) compared to sequencing batch reactors due to their enhanced filtration capability and consistent sludge quality.

Cyclic Operation

Membrane bioreactors use continuous filtration during cyclic operation to enhance sludge retention, while sequencing batch reactors rely on time-controlled batch processing phases for nutrient removal and biomass settling.

membrane bioreactor vs sequencing batch reactor Infographic

njnir.com

njnir.com