Biochar offers a sustainable alternative to activated carbon in environmental engineering due to its lower production cost and renewable feedstock origins. Its porous structure enhances soil fertility and carbon sequestration while effectively adsorbing pollutants, making it ideal for water and air purification applications. Unlike activated carbon, biochar's environmental benefits include reduced greenhouse gas emissions and improved ecosystem health, supporting circular economy principles.

Table of Comparison

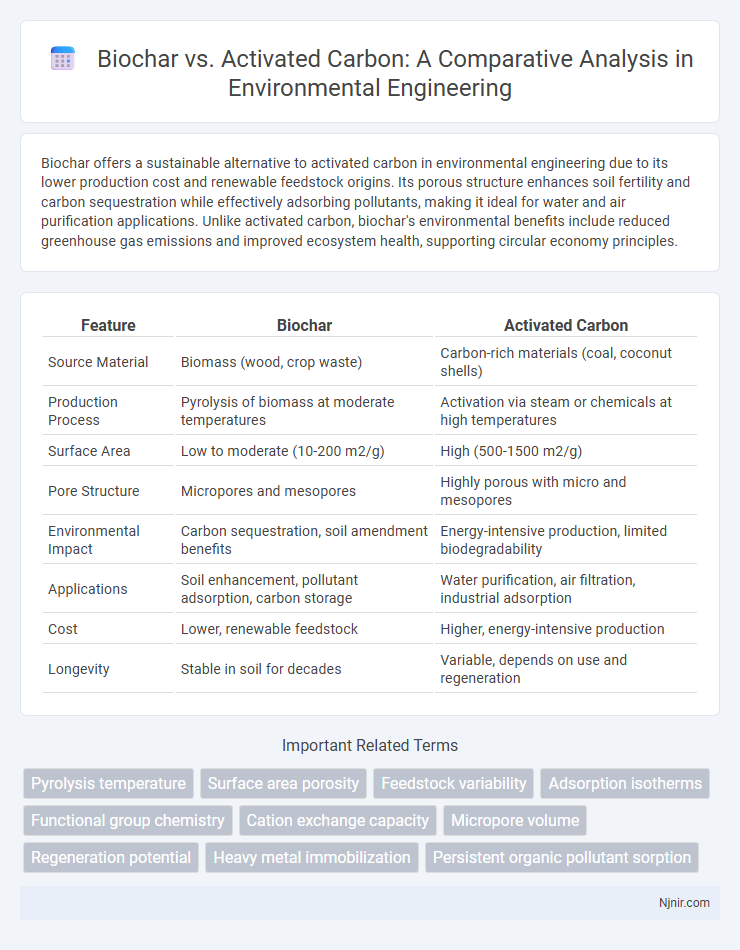

| Feature | Biochar | Activated Carbon |

|---|---|---|

| Source Material | Biomass (wood, crop waste) | Carbon-rich materials (coal, coconut shells) |

| Production Process | Pyrolysis of biomass at moderate temperatures | Activation via steam or chemicals at high temperatures |

| Surface Area | Low to moderate (10-200 m2/g) | High (500-1500 m2/g) |

| Pore Structure | Micropores and mesopores | Highly porous with micro and mesopores |

| Environmental Impact | Carbon sequestration, soil amendment benefits | Energy-intensive production, limited biodegradability |

| Applications | Soil enhancement, pollutant adsorption, carbon storage | Water purification, air filtration, industrial adsorption |

| Cost | Lower, renewable feedstock | Higher, energy-intensive production |

| Longevity | Stable in soil for decades | Variable, depends on use and regeneration |

Introduction to Biochar and Activated Carbon

Biochar is a carbon-rich product derived from the pyrolysis of biomass under limited oxygen conditions, primarily used for soil enhancement and carbon sequestration. Activated carbon, produced from charcoal, coal, or coconut shells through physical or chemical activation, features a highly porous structure ideal for adsorption in water and air purification. Both biochar and activated carbon offer significant environmental benefits, but their production methods and application purposes differ markedly.

Raw Materials and Production Processes

Biochar is primarily produced from biomass materials such as agricultural residues, wood chips, and organic waste through pyrolysis at temperatures between 350-700degC in an oxygen-limited environment. Activated carbon, conversely, is typically derived from charcoal, coal, coconut shells, or peat and undergoes physical or chemical activation involving higher temperatures (600-1200degC) and activating agents like steam or phosphoric acid to enhance porosity. The differing raw materials and production conditions result in distinct surface properties, with biochar often retaining more mineral content while activated carbon exhibits higher surface area and adsorption capacity.

Physical and Chemical Properties Comparison

Biochar exhibits a porous structure with a high surface area typically ranging between 200-400 m2/g, composed primarily of carbonized biomass rich in aromatic carbon compounds, while activated carbon boasts an even greater surface area often exceeding 1000 m2/g, characterized by a highly developed microporous network and abundant oxygen-containing functional groups. Chemically, biochar contains alkaline minerals such as calcium, potassium, and magnesium, contributing to a higher pH and cation exchange capacity, whereas activated carbon is predominantly pure carbon with controlled surface chemistry optimized for adsorption through acid treatments or steam activation. The differences in pore size distribution, surface functionality, and elemental composition directly influence their adsorption capacities and applications in environmental remediation and catalysis.

Applications in Water and Air Purification

Biochar and activated carbon serve as effective adsorbents in water and air purification, with biochar excelling in removing heavy metals, nutrients, and organic pollutants due to its porous structure derived from biomass pyrolysis. Activated carbon features a higher surface area and greater pore volume, enabling superior adsorption of volatile organic compounds (VOCs), odors, and toxic gases in air purification systems. Both materials contribute to sustainable environmental management, though activated carbon is preferred for industrial-scale filtration while biochar supports eco-friendly wastewater treatment and soil amendment.

Environmental Impact and Sustainability

Biochar and activated carbon both offer significant environmental benefits, but biochar is considered more sustainable due to its ability to sequester carbon in soils for decades, improving soil health and reducing greenhouse gas emissions. Activated carbon, while effective for pollutant adsorption in water and air, typically requires energy-intensive production processes that rely on non-renewable resources. The sustainable use of biochar supports circular bioeconomy principles by utilizing agricultural waste, enhancing carbon cycling, and reducing reliance on fossil-based materials.

Adsorption Capacity and Efficiency

Biochar and activated carbon differ significantly in adsorption capacity and efficiency, with activated carbon generally exhibiting higher surface area, often exceeding 1000 m2/g, compared to biochar's 100-400 m2/g range. The enhanced pore structure and functional groups in activated carbon contribute to superior removal of contaminants like heavy metals and organic pollutants in water treatment. However, biochar offers competitive adsorption efficiency in specific applications due to its lower production costs and sustainability benefits.

Cost Analysis and Economic Feasibility

Biochar typically offers a lower production cost compared to activated carbon due to its simpler pyrolysis processes and the use of abundant biomass waste, making it economically feasible for large-scale agricultural and environmental applications. Activated carbon requires higher energy input and chemical treatments, which increase its operational costs and market price, limiting its affordability for some industrial uses. Cost analysis shows biochar's potential as a sustainable, cost-effective alternative for water treatment and soil amendment, especially in resource-limited settings.

Regeneration and Reusability

Biochar exhibits moderate regeneration potential through thermal treatment but often suffers from reduced adsorption capacity after multiple cycles due to structural changes. Activated carbon demonstrates superior regeneration and reusability, maintaining high adsorption efficiency after repeated chemical or thermal regeneration processes. The enhanced porosity and surface area stability of activated carbon make it more suitable for applications requiring frequent regeneration and prolonged use.

Challenges and Limitations

Biochar faces challenges such as variable adsorption capacity due to feedstock inconsistency and lower surface area compared to activated carbon. Activated carbon, while highly effective for adsorption, suffers from high production costs and energy-intensive manufacturing processes. Both materials encounter limitations in regeneration efficiency and potential environmental impacts during disposal.

Future Trends in Environmental Remediation

Future trends in environmental remediation emphasize the growing use of biochar due to its sustainable production from biomass and high adsorption capacity for pollutants such as heavy metals and organic compounds. Activated carbon remains a benchmark for contaminant removal but faces challenges related to high production costs and non-renewability, driving research toward more eco-friendly alternatives like biochar. Advances in biochar modification techniques and integration with nanomaterials are expected to enhance its efficiency, positioning biochar as a key material in next-generation environmental cleanup technologies.

Pyrolysis temperature

Pyrolysis temperature significantly influences biochar's porous structure and adsorption capacity, with higher temperatures enhancing surface area and functionality compared to activated carbon typically produced at controlled elevated temperatures for consistent adsorption performance.

Surface area porosity

Biochar typically has lower surface area and less developed porosity compared to activated carbon, which features highly porous structures and significantly greater surface area, enhancing its adsorption capacity.

Feedstock variability

Biochar's feedstock variability significantly influences its porosity and adsorption capacity, whereas activated carbon typically derives from more consistent, high-carbon materials ensuring uniform performance.

Adsorption isotherms

Biochar exhibits distinct adsorption isotherms compared to activated carbon, typically showing lower adsorption capacity and different affinity patterns due to its porous structure and surface chemistry variations.

Functional group chemistry

Biochar contains abundant oxygen-containing functional groups such as hydroxyl, carboxyl, and carbonyl, enhancing its adsorption capacity, whereas activated carbon primarily features a higher density of aromatic and graphitic structures with surface functionalities that vary based on activation methods.

Cation exchange capacity

Biochar generally exhibits a lower cation exchange capacity (CEC) than activated carbon due to its porous structure and surface functional groups, making activated carbon more effective for ion exchange applications.

Micropore volume

Biochar typically exhibits lower micropore volume compared to activated carbon, which possesses a highly developed microporous structure essential for superior adsorption capacity.

Regeneration potential

Biochar demonstrates higher regeneration potential than activated carbon due to its stable porous structure and lower energy requirements for restoration.

Heavy metal immobilization

Biochar demonstrates superior heavy metal immobilization compared to activated carbon due to its higher cation exchange capacity and porous structure enhancing metal adsorption and stabilization in contaminated soils.

Persistent organic pollutant sorption

Biochar demonstrates competitive sorption capacities for persistent organic pollutants compared to activated carbon, benefiting from its porous structure and surface functional groups that enhance pollutant adsorption efficiency.

biochar vs activated carbon Infographic

njnir.com

njnir.com