Fly ash consists of fine particles captured from the flue gases of coal combustion, characterized by its pozzolanic properties that enhance concrete strength and durability. Bottom ash, coarser and heavier, accumulates at the furnace base and serves primarily as a structural fill material in construction projects. Effective management and reuse of both fly ash and bottom ash reduce landfill disposal, lower carbon emissions, and promote sustainable waste utilization in environmental engineering.

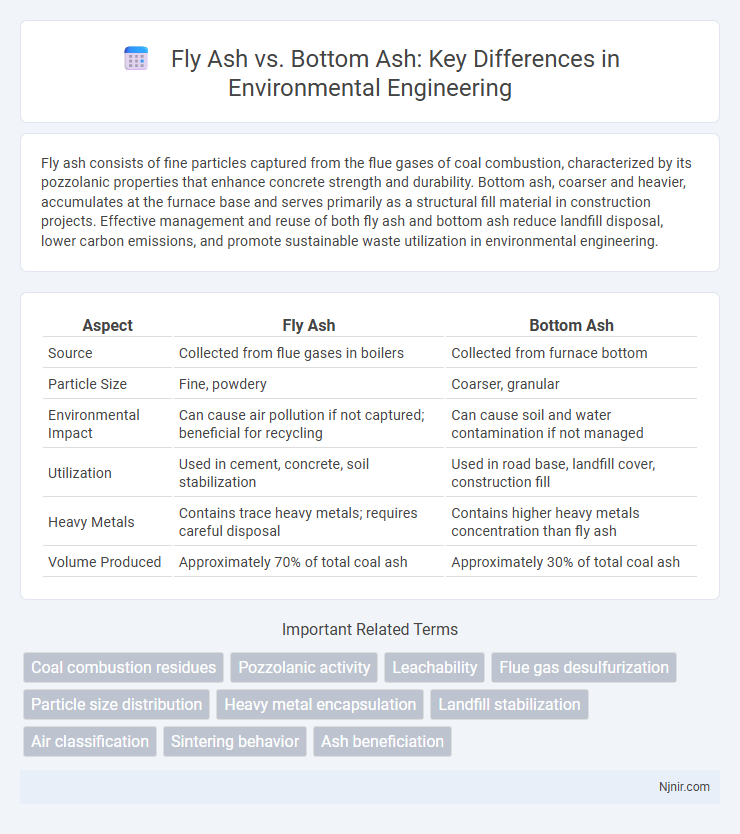

Table of Comparison

| Aspect | Fly Ash | Bottom Ash |

|---|---|---|

| Source | Collected from flue gases in boilers | Collected from furnace bottom |

| Particle Size | Fine, powdery | Coarser, granular |

| Environmental Impact | Can cause air pollution if not captured; beneficial for recycling | Can cause soil and water contamination if not managed |

| Utilization | Used in cement, concrete, soil stabilization | Used in road base, landfill cover, construction fill |

| Heavy Metals | Contains trace heavy metals; requires careful disposal | Contains higher heavy metals concentration than fly ash |

| Volume Produced | Approximately 70% of total coal ash | Approximately 30% of total coal ash |

Introduction to Fly Ash and Bottom Ash

Fly ash and bottom ash are two primary by-products of coal combustion in power plants, differing in texture and composition. Fly ash consists of fine, powdery particles captured from flue gases by electrostatic precipitators, whereas bottom ash is a coarser material collected at the furnace bottom. Both materials possess unique properties that influence their applications in construction, such as in cement, concrete, and road base production.

Formation Processes of Fly Ash and Bottom Ash

Fly ash forms during the combustion of pulverized coal, where fine particles are carried away with flue gases and collected by electrostatic precipitators or fabric filters, resulting in a fine, powdery material. Bottom ash, in contrast, originates from the molten ash that settles at the furnace's bottom, solidifying into coarser, heavier particles after cooling. The distinct formation processes influence their physical characteristics, reactivity, and potential applications in construction and environmental remediation.

Physical and Chemical Properties: Fly Ash vs Bottom Ash

Fly ash consists of fine, spherical particles with a high silica and alumina content, exhibiting pozzolanic properties that enhance cementitious reactions, while bottom ash is coarser with irregular, porous particles and higher carbon content. Chemically, fly ash typically contains lower unburned carbon and fewer heavy metals compared to bottom ash, which has higher iron and calcium oxides due to incomplete combustion. The physical fineness and chemical composition differences influence their suitability for various applications in construction and environmental management.

Environmental Impacts of Fly Ash and Bottom Ash Disposal

Fly ash disposal often raises concerns due to its fine particulate nature and potential for heavy metal leaching, posing risks to air and water quality, while bottom ash, being coarser and heavier, typically presents lower airborne pollution risks but requires careful management to prevent groundwater contamination. Landfilling fly ash can lead to toxic emissions and groundwater pollution if not properly contained, whereas bottom ash's larger particle size allows for safer reuse in construction materials, reducing environmental burdens. Proper disposal methods and recycling strategies for both ashes are critical to minimizing their ecological footprint and protecting surrounding ecosystems.

Utilization and Recycling Opportunities

Fly ash, a fine powder byproduct from coal combustion, is widely utilized in concrete production to enhance strength and durability, while bottom ash, coarser and heavier, finds applications in road base materials and structural fill. Recycling fly ash in cement manufacturing reduces landfill waste and lowers carbon emissions, whereas bottom ash is increasingly used in lightweight aggregate production and soil stabilization projects. Both ashes present significant opportunities for sustainable construction practices by diverting industrial waste into valuable raw materials.

Regulatory Standards and Guidelines

Fly ash and bottom ash are regulated under environmental standards such as the EPA's Coal Combustion Residuals (CCR) Rule, which classifies both as coal combustion byproducts requiring proper disposal and management to prevent groundwater contamination. Fly ash often faces stricter guidelines due to its finer particle size and higher potential for airborne dispersion, necessitating specific measures in storage and handling to comply with air quality standards. Bottom ash regulations emphasize stable landfilling and structural use criteria, ensuring materials meet safety thresholds for leaching and heavy metal content under hazardous waste regulations.

Leaching Potential and Toxicity Concerns

Fly ash exhibits a higher leaching potential for heavy metals such as arsenic, lead, and mercury compared to bottom ash, posing greater environmental risks when improperly managed. Bottom ash often contains coarser particles with lower surface area, resulting in reduced leachate toxicity but can still release contaminants under acidic conditions. Effective stabilization and encapsulation techniques are essential to mitigate leaching and toxicity concerns for both fly ash and bottom ash in construction and waste disposal applications.

Applications in Construction and Infrastructure

Fly ash is widely used as a supplementary cementitious material in concrete production, enhancing strength, durability, and workability, making it ideal for infrastructure projects like bridges, roads, and high-rise buildings. Bottom ash, with its coarser texture, is commonly utilized as a lightweight aggregate in road base layers, embankments, and drainage systems, providing excellent stability and permeability. Both materials contribute to sustainable construction by recycling industrial by-products, reducing landfill waste, and decreasing the environmental impact of traditional construction materials.

Advances in Treatment and Management Technologies

Recent advances in treatment and management technologies for fly ash and bottom ash focus on enhancing resource recovery and environmental safety. Innovations include the development of thermal stabilization, chemical solidification, and bioleaching techniques to immobilize heavy metals and reduce leachate toxicity. Advanced separation and valorization processes convert both fly ash and bottom ash into construction materials, promoting sustainable waste recycling and minimizing landfill dependency.

Future Trends and Research Directions

Future trends in fly ash and bottom ash utilization emphasize the development of advanced materials for sustainable construction, such as geopolymer cement and high-performance concrete composites. Research directions focus on improving ash beneficiation techniques to enhance their pozzolanic properties and reduce environmental impacts through carbon capture integration. Innovations in nano-engineering and hybrid ash blends aim to maximize resource efficiency and promote circular economy practices in the construction and energy sectors.

Coal combustion residues

Fly ash, composed mainly of fine particles collected from flue gases, has higher pozzolanic properties and is widely used in concrete production, whereas bottom ash consists of coarser, heavier particles collected from the furnace bottom, often utilized in construction fill and road base applications within coal combustion residues management.

Pozzolanic activity

Fly ash exhibits higher pozzolanic activity than bottom ash due to its finer particle size and greater silica and alumina content, enhancing cement hydration and strength development.

Leachability

Fly ash exhibits lower leachability of heavy metals compared to bottom ash, making it generally more environmentally stable for disposal and construction use.

Flue gas desulfurization

Fly ash contains higher silica and alumina content ideal for flue gas desulfurization sorbents, while bottom ash's coarser texture limits its effectiveness in capturing sulfur dioxide emissions during the desulfurization process.

Particle size distribution

Fly ash typically exhibits a finer particle size distribution, predominantly under 100 microns, while bottom ash consists of coarser particles generally larger than 500 microns.

Heavy metal encapsulation

Fly ash demonstrates superior heavy metal encapsulation compared to bottom ash due to its finer particle size and higher pozzolanic content, which enhance immobilization and reduce leaching risks in construction materials.

Landfill stabilization

Fly ash, with its finer particles and higher pozzolanic properties compared to bottom ash, significantly enhances landfill stabilization by improving soil strength and reducing leachate contaminants.

Air classification

Air classification of fly ash and bottom ash separates fine fly ash particles for cement additives while coarse bottom ash is screened for construction aggregates.

Sintering behavior

Fly ash demonstrates lower sintering temperatures and enhanced fusion characteristics compared to bottom ash, making it more suitable for high-strength cementitious applications.

Ash beneficiation

Fly ash, richer in pozzolanic properties and finer particles, offers higher efficiency in ash beneficiation processes compared to the coarser, denser bottom ash, enhancing its suitability for use in cement and construction materials.

fly ash vs bottom ash Infographic

njnir.com

njnir.com