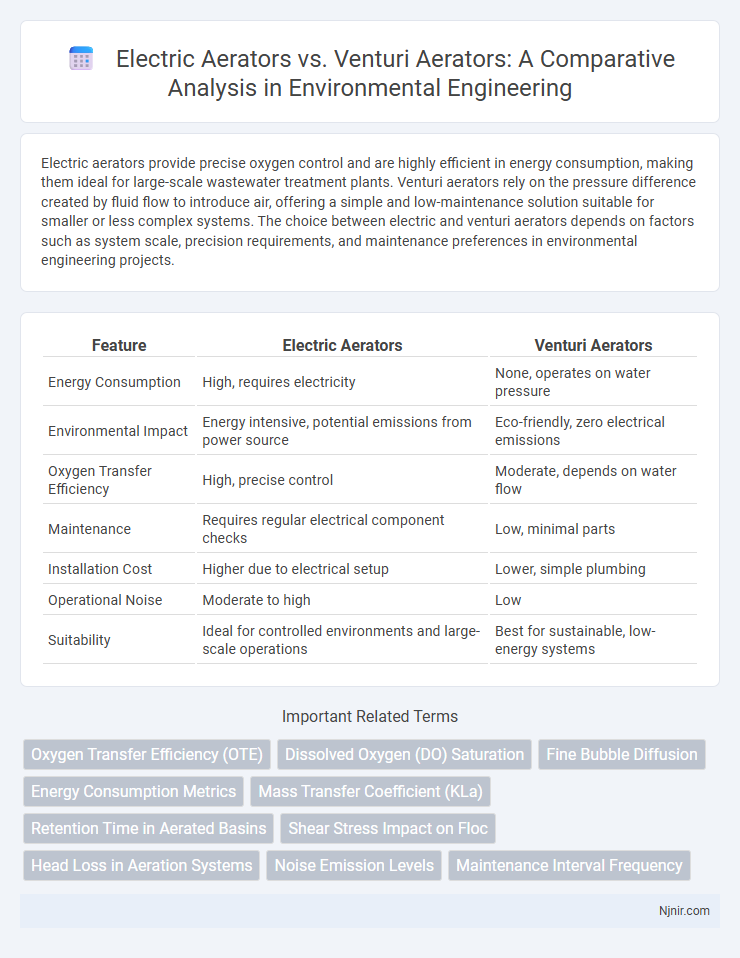

Electric aerators provide precise oxygen control and are highly efficient in energy consumption, making them ideal for large-scale wastewater treatment plants. Venturi aerators rely on the pressure difference created by fluid flow to introduce air, offering a simple and low-maintenance solution suitable for smaller or less complex systems. The choice between electric and venturi aerators depends on factors such as system scale, precision requirements, and maintenance preferences in environmental engineering projects.

Table of Comparison

| Feature | Electric Aerators | Venturi Aerators |

|---|---|---|

| Energy Consumption | High, requires electricity | None, operates on water pressure |

| Environmental Impact | Energy intensive, potential emissions from power source | Eco-friendly, zero electrical emissions |

| Oxygen Transfer Efficiency | High, precise control | Moderate, depends on water flow |

| Maintenance | Requires regular electrical component checks | Low, minimal parts |

| Installation Cost | Higher due to electrical setup | Lower, simple plumbing |

| Operational Noise | Moderate to high | Low |

| Suitability | Ideal for controlled environments and large-scale operations | Best for sustainable, low-energy systems |

Introduction to Aeration Technologies in Environmental Engineering

Electric aerators utilize mechanical energy to introduce oxygen into water, enhancing biochemical processes in wastewater treatment and aquaculture systems. Venturi aerators leverage fluid dynamics by forcing water through a constricted throat, creating a vacuum that draws and mixes air efficiently into the liquid stream. Both technologies optimize oxygen transfer rates critical for microbial activity and pollutant degradation in environmental engineering applications.

Principles of Electric Aerators

Electric aerators operate by using a motor-driven impeller or turbine to force air directly into the water, creating fine bubbles that enhance oxygen transfer efficiently. This mechanical mechanism ensures consistent aeration pressure and flow rates, optimizing dissolved oxygen levels crucial for aquatic systems or wastewater treatment. Unlike venturi aerators that rely on water velocity to draw in air, electric aerators provide precise control over aeration intensity and can handle varying water qualities with greater reliability.

Principles of Venturi Aerators

Venturi aerators operate on the principle of fluid dynamics, using the Venturi effect to inject air into water by creating a pressure difference as water flows through a narrowed section of pipe. This causes air to be drawn into the stream without the need for electrical power, making Venturi aerators energy-efficient and low-maintenance. Unlike electric aerators, which rely on mechanical components and electricity to mix air and water, Venturi aerators use hydraulic pressure variations to achieve effective aeration.

Energy Efficiency Comparison: Electric vs. Venturi Aerators

Electric aerators consume less energy by utilizing advanced motor technology to maximize oxygen transfer efficiency, often achieving oxygen transfer efficiencies (OTE) of up to 3.0 kg O2/kWh. Venturi aerators, relying on fluid dynamics without external power, have lower energy input but typically achieve OTE between 1.5 to 2.0 kg O2/kWh, resulting in higher energy consumption per unit of oxygen transferred when powered by pumps. Comparing energy efficiency, electric aerators offer superior performance in oxygen transfer per kilowatt-hour, making them more cost-effective and environmentally sustainable for high-demand aeration systems.

Operational and Maintenance Requirements

Electric aerators require continuous power supply and periodic motor maintenance, including lubrication and electrical inspections, to ensure efficient operation, while venturi aerators operate without external power, relying solely on water flow, resulting in lower energy costs and simpler mechanical upkeep. Venturi aerators have fewer moving parts, minimizing wear and reducing downtime, but they may need regular cleaning to prevent clogging and maintain optimal performance. Both systems require monitoring to avoid fouling and ensure consistent oxygen transfer rates, although electric aerators typically demand more frequent maintenance interventions due to their mechanical complexity.

Oxygen Transfer Rates and Aeration Effectiveness

Electric aerators deliver higher oxygen transfer rates (OTR) by actively forcing air or oxygen into water through mechanical agitation, ensuring enhanced aeration effectiveness in various aquatic environments. Venturi aerators rely on the pressure differential created by water flow to draw air into the water, typically resulting in lower OTR compared to electric models but offering energy-efficient operation. For applications demanding rapid oxygen replenishment, electric aerators provide superior performance, while venturi aerators excel in systems prioritizing low energy consumption and simplicity.

Environmental Impact and Sustainability

Electric aerators consume electrical energy, potentially contributing to carbon emissions depending on the energy source, but they provide precise oxygenation control, enhancing water quality and supporting aquatic ecosystems sustainably. Venturi aerators operate without external power using water flow to introduce air, minimizing energy consumption and greenhouse gas emissions, which aligns with eco-friendly and low-carbon water management practices. Both systems impact environmental sustainability, with electric aerators offering advanced control for intensive applications and venturi aerators excelling in energy-efficient, passive oxygenation methods.

Cost Analysis: Installation and Long-term Operation

Electric aerators generally have higher initial installation costs due to complex components and power requirements, while Venturi aerators are more affordable to install with simpler designs and no need for external power sources. Long-term operation costs favor Venturi aerators because they rely on system pressure rather than electricity, reducing ongoing energy expenses, whereas electric aerators incur continuous power consumption and potential maintenance of mechanical parts. Considering both installation and operational expenses, Venturi aerators offer greater cost-efficiency for large-scale or long-duration aeration projects.

Suitability for Various Applications and Environments

Electric aerators provide precise oxygen control and are suitable for large-scale aquaculture and industrial wastewater treatment due to their high efficiency and adaptability to varying environmental conditions. Venturi aerators excel in energy-efficient oxygen transfer with minimal maintenance, making them ideal for ponds, tanks, and rural applications where power supply is limited. Selection depends on site-specific factors such as water volume, oxygen demand, and power availability, ensuring optimal aeration performance across diverse applications.

Future Trends in Aeration Technology

Electric aerators are advancing with energy-efficient designs and IoT integration for real-time monitoring, enhancing precision in oxygen delivery. Venturi aerators are evolving through optimized nozzle geometry and hybrid models to improve gas transfer rates while reducing maintenance. Future trends indicate a convergence of smart technology and sustainable materials, driving higher productivity and lower environmental impact in aeration systems.

Oxygen Transfer Efficiency (OTE)

Electric aerators typically achieve higher Oxygen Transfer Efficiency (OTE) than Venturi aerators due to their controlled airflow and consistent mixing mechanisms.

Dissolved Oxygen (DO) Saturation

Electric aerators achieve higher Dissolved Oxygen (DO) saturation levels compared to venturi aerators due to their enhanced oxygen transfer efficiency and consistent aeration performance.

Fine Bubble Diffusion

Electric aerators generate highly efficient fine bubble diffusion by using mechanical agitation, whereas Venturi aerators rely on fluid flow dynamics to produce fine bubbles, resulting in differing oxygen transfer rates and energy efficiencies.

Energy Consumption Metrics

Electric aerators typically consume 30-50% less energy than Venturi aerators while delivering equivalent oxygen transfer rates in wastewater treatment applications.

Mass Transfer Coefficient (KLa)

Electric aerators generally achieve higher Mass Transfer Coefficient (KLa) values compared to venturi aerators, enhancing oxygen dissolution efficiency in water treatment processes.

Retention Time in Aerated Basins

Electric aerators provide more consistent and adjustable oxygen transfer rates, resulting in optimized retention time and improved treatment efficiency in aerated basins compared to Venturi aerators, which rely on fluid velocity and may have less precise control over retention time.

Shear Stress Impact on Floc

Electric aerators generate higher shear stress that can damage floc structure, whereas venturi aerators provide gentler mixing, preserving floc integrity and enhancing sedimentation efficiency.

Head Loss in Aeration Systems

Electric aerators typically exhibit lower head loss compared to venturi aerators, enhancing overall system efficiency by reducing energy consumption in aeration processes.

Noise Emission Levels

Electric aerators typically emit lower noise levels, averaging around 50-60 decibels, whereas venturi aerators produce higher noise emissions, often exceeding 70 decibels.

Maintenance Interval Frequency

Electric aerators require maintenance every 6 to 12 months, while Venturi aerators typically need servicing less frequently, about every 12 to 18 months, due to their simpler design and fewer moving parts.

electric aerators vs venturi aerators Infographic

njnir.com

njnir.com