Hydraulic fracturing enhances natural rock permeability by injecting high-pressure fluids to release trapped hydrocarbons, making it more effective than conventional drilling in accessing deep shale formations. Conventional drilling relies on vertical wells and natural reservoir pressure, often limiting extraction to accessible zones with higher permeability. The advanced technology of hydraulic fracturing significantly increases production rates but raises environmental concerns like groundwater contamination and induced seismicity.

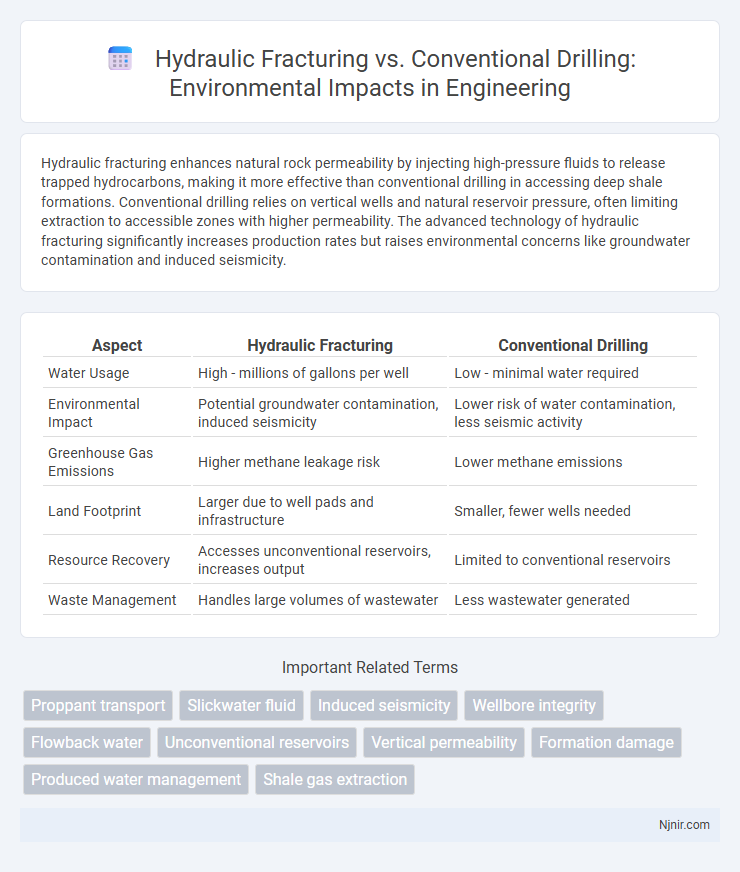

Table of Comparison

| Aspect | Hydraulic Fracturing | Conventional Drilling |

|---|---|---|

| Water Usage | High - millions of gallons per well | Low - minimal water required |

| Environmental Impact | Potential groundwater contamination, induced seismicity | Lower risk of water contamination, less seismic activity |

| Greenhouse Gas Emissions | Higher methane leakage risk | Lower methane emissions |

| Land Footprint | Larger due to well pads and infrastructure | Smaller, fewer wells needed |

| Resource Recovery | Accesses unconventional reservoirs, increases output | Limited to conventional reservoirs |

| Waste Management | Handles large volumes of wastewater | Less wastewater generated |

Introduction to Hydraulic Fracturing and Conventional Drilling

Hydraulic fracturing, commonly known as fracking, involves injecting high-pressure fluid into subterranean rock formations to create fractures, enhancing oil and gas extraction from shale formations. Conventional drilling relies on vertical boreholes targeting porous rock reservoirs where hydrocarbons naturally accumulate, requiring less intensive stimulation. Hydraulic fracturing significantly increases access to otherwise inaccessible resources, revolutionizing energy production by unlocking vast shale gas and oil reserves.

Overview of Extraction Methods

Hydraulic fracturing involves injecting high-pressure fluid to create fractures in rock formations, enabling the extraction of oil and gas from shale and tight reservoirs. Conventional drilling accesses reservoirs with naturally occurring permeability, relying on the natural flow of hydrocarbons into the wellbore. Both methods differ significantly in technology, environmental impact, and the types of geological formations they target.

Geological Suitability and Site Selection

Hydraulic fracturing is best suited for unconventional reservoirs such as shale, tight sandstones, and coal beds where natural permeability is low, enabling enhanced hydrocarbon flow through induced fractures. Conventional drilling targets reservoirs with sufficient natural porosity and permeability, typically found in sandstone or carbonate formations, requiring less complex stimulation techniques. Site selection for hydraulic fracturing demands detailed geological analysis including rock brittleness, stress orientation, and depth to optimize fracture propagation, whereas conventional drilling prioritizes reservoir thickness, trap integrity, and hydrocarbon saturation for efficient production.

Water Usage and Management

Hydraulic fracturing consumes significantly more water than conventional drilling, often requiring millions of gallons per well to fracture rock formations and release hydrocarbons. Effective water management strategies in hydraulic fracturing include recycling flowback and produced water to reduce freshwater withdrawal and minimize environmental impact. Conventional drilling typically uses less water, relying mainly on water-based mud and drilling fluids, but its water footprint increases when enhanced recovery methods are employed.

Chemical Additives and Environmental Risks

Hydraulic fracturing utilizes chemical additives such as biocides, surfactants, and corrosion inhibitors to enhance fluid performance, whereas conventional drilling relies on fewer chemicals primarily for lubrication and mud control. The extensive use of chemicals in hydraulic fracturing increases the risk of groundwater contamination and surface spills, posing significant environmental hazards. Conventional drilling's environmental risks center mostly on soil disturbance and waste drilling fluids, which are generally less chemically intensive compared to fracking operations.

Surface and Groundwater Contamination

Hydraulic fracturing involves injecting high-pressure fluids to create fractures in underground rock formations, which increases the risk of surface spills and groundwater contamination due to chemical additives and flowback water leakage. Conventional drilling typically poses a lower contamination risk as it relies on more straightforward extraction methods with fewer chemical inputs, reducing the likelihood of groundwater infiltration. Both methods require stringent monitoring and containment measures to protect surface and groundwater quality from potential contamination.

Air Quality Impacts and Emissions

Hydraulic fracturing generates higher levels of volatile organic compounds (VOCs) and methane emissions compared to conventional drilling, significantly contributing to ground-level ozone formation and greenhouse gas accumulation. Diesel engines used in hydraulic fracturing operations emit nitrogen oxides (NOx) and particulate matter that deteriorate local air quality near well sites. Conventional drilling typically results in lower overall emissions due to less intensive extraction processes and reduced flaring and venting activities.

Land Disturbance and Habitat Disruption

Hydraulic fracturing typically causes less surface land disturbance compared to conventional drilling due to its ability to access multiple reservoirs from a single well pad, minimizing the overall footprint. Conventional drilling requires multiple well sites, leading to extensive clearing and fragmentation of habitats, which significantly disrupts local ecosystems. The concentrated nature of hydraulic fracturing operations reduces habitat loss, but risks such as groundwater contamination still pose environmental challenges.

Waste Generation and Disposal Concerns

Hydraulic fracturing generates significantly more wastewater compared to conventional drilling, often containing higher concentrations of hazardous chemicals, heavy metals, and radioactive materials. Proper disposal of fracking fluids requires advanced treatment methods or deep well injection to prevent soil and water contamination, posing substantial environmental challenges. In contrast, conventional drilling produces less waste with lower toxicity, simplifying disposal but still requiring careful management to avoid pollution risks.

Regulatory Frameworks and Environmental Compliance

Hydraulic fracturing operations are subject to stringent regulatory frameworks that mandate comprehensive environmental compliance measures such as groundwater protection, air quality standards, and waste management protocols. Conventional drilling, while also regulated, typically faces less intensive oversight due to its lower risk profile in relation to induced seismicity and chemical usage. Regulatory agencies enforce rigorous monitoring and reporting requirements for both methods to mitigate environmental impacts and ensure adherence to federal and state laws.

Proppant transport

Hydraulic fracturing enhances proppant transport efficiency by creating high-conductivity fractures, enabling greater hydrocarbon flow compared to conventional drilling's limited natural fracture networks.

Slickwater fluid

Slickwater fluid enhances hydraulic fracturing by reducing friction and increasing fracture complexity, resulting in higher hydrocarbon recovery compared to conventional drilling methods.

Induced seismicity

Hydraulic fracturing induces seismicity by creating microseismic events typically below magnitude 3, whereas conventional drilling rarely triggers noticeable seismic activity due to minimal subsurface pressure changes.

Wellbore integrity

Hydraulic fracturing enhances hydrocarbon recovery but poses greater wellbore integrity risks compared to conventional drilling due to increased pressure-induced fractures and cement degradation.

Flowback water

Flowback water from hydraulic fracturing contains higher concentrations of chemicals and contaminants compared to conventional drilling, posing greater environmental and treatment challenges.

Unconventional reservoirs

Hydraulic fracturing enhances oil and gas extraction from unconventional reservoirs by creating artificial fractures to improve permeability, unlike conventional drilling that relies on natural reservoir permeability.

Vertical permeability

Hydraulic fracturing significantly enhances vertical permeability in shale formations compared to conventional drilling, enabling increased hydrocarbon flow through otherwise low-permeability rocks.

Formation damage

Hydraulic fracturing mitigates formation damage by enhancing reservoir permeability through induced fractures, whereas conventional drilling often causes significant formation damage due to mechanical disruption and fluid invasion.

Produced water management

Produced water management in hydraulic fracturing requires advanced treatment technologies to handle higher volumes and complex chemical compositions compared to conventional drilling.

Shale gas extraction

Hydraulic fracturing significantly enhances shale gas extraction by increasing well productivity and accessing otherwise impermeable rock formations compared to conventional drilling methods.

hydraulic fracturing vs conventional drilling Infographic

njnir.com

njnir.com