Living building materials, such as mycelium-based composites and bio-cement, offer sustainable alternatives to traditional concrete by reducing carbon emissions and enhancing biodegradability. These materials actively contribute to carbon sequestration during their lifecycle, unlike conventional concrete, which is responsible for significant CO2 release during production. Incorporating living building materials into construction promotes environmental resilience and reduces the ecological footprint of infrastructure projects.

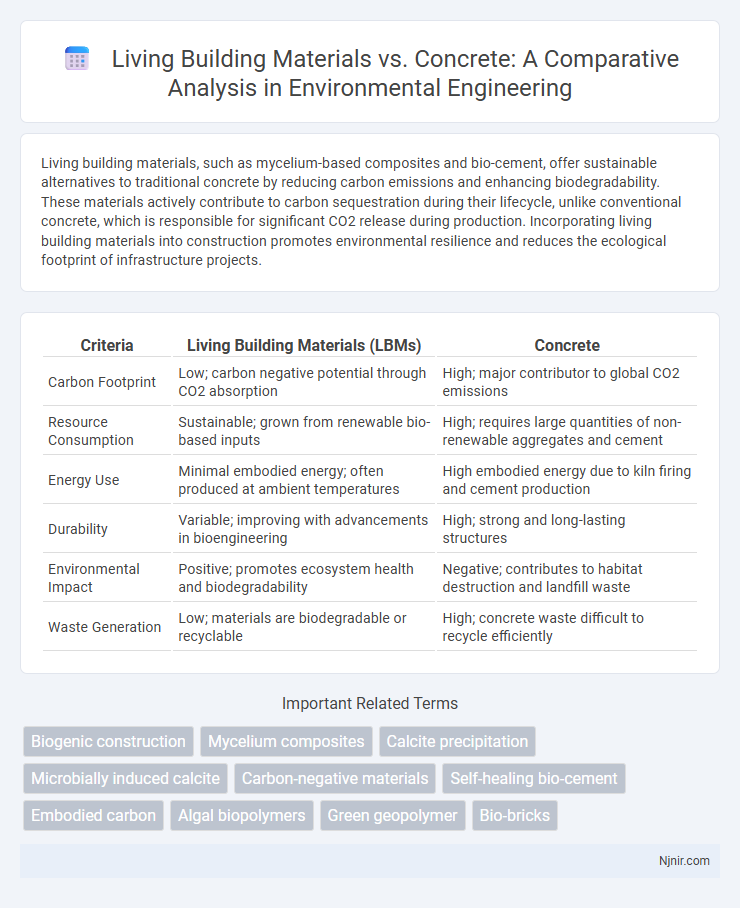

Table of Comparison

| Criteria | Living Building Materials (LBMs) | Concrete |

|---|---|---|

| Carbon Footprint | Low; carbon negative potential through CO2 absorption | High; major contributor to global CO2 emissions |

| Resource Consumption | Sustainable; grown from renewable bio-based inputs | High; requires large quantities of non-renewable aggregates and cement |

| Energy Use | Minimal embodied energy; often produced at ambient temperatures | High embodied energy due to kiln firing and cement production |

| Durability | Variable; improving with advancements in bioengineering | High; strong and long-lasting structures |

| Environmental Impact | Positive; promotes ecosystem health and biodegradability | Negative; contributes to habitat destruction and landfill waste |

| Waste Generation | Low; materials are biodegradable or recyclable | High; concrete waste difficult to recycle efficiently |

Introduction to Living Building Materials and Traditional Concrete

Living building materials, such as bio-based composites and self-healing concrete, offer sustainable alternatives by reducing carbon emissions and enhancing durability through natural processes. Traditional concrete, a composite of cement, water, sand, and aggregates, is widely used for its strength and versatility but generates significant CO2 during cement production. Emerging living materials integrate microorganisms like bacteria or fungi to repair cracks and improve longevity, presenting a promising shift towards eco-friendly construction.

Environmental Impact: Carbon Footprint Comparison

Living building materials, such as engineered wood and hempcrete, significantly reduce the carbon footprint compared to traditional concrete by sequestering carbon dioxide during growth and requiring less energy-intensive processing. Concrete production accounts for approximately 8% of global CO2 emissions due to the calcination of limestone and fossil fuel consumption, making it one of the largest industrial contributors to greenhouse gases. Utilizing living materials not only lowers embodied carbon but also promotes circular economy principles, offering sustainable alternatives with enhanced environmental performance in construction.

Material Composition and Sustainability

Living building materials consist primarily of organic components such as mycelium, bacteria, and natural fibers, which enable self-healing and carbon sequestration, significantly reducing environmental impact. Concrete is composed of cement, aggregates, and water, with cement production responsible for approximately 8% of global CO2 emissions, posing sustainability challenges. The biodegradability and regenerative properties of living materials contrast sharply with concrete's finite lifecycle and high embodied energy, positioning living materials as a more sustainable alternative for eco-friendly construction.

Structural Performance and Durability

Living building materials, such as mycelium composites or engineered bamboo, offer excellent structural performance with high strength-to-weight ratios and natural resilience, making them suitable for various load-bearing applications. These materials demonstrate superior durability through self-healing properties and biodegradability, reducing environmental degradation compared to traditional concrete. While concrete provides exceptional compressive strength and long-lasting durability in harsh conditions, its susceptibility to cracking and environmental impact highlights the advantages of sustainable living materials in modern construction.

Energy Efficiency and Thermal Properties

Living building materials such as rammed earth and straw bales offer superior energy efficiency by enhancing natural insulation and reducing reliance on artificial heating and cooling systems. Unlike conventional concrete, which has high thermal conductivity and retains heat, living materials provide better thermal mass regulation, stabilizing indoor temperatures and lowering energy consumption. This leads to reduced carbon footprints and improved sustainability in building design.

Life Cycle Assessment: Longevity and End-of-Life Options

Living building materials such as timber and mycelium composites demonstrate superior Life Cycle Assessment (LCA) profiles due to their renewability, carbon sequestration capabilities, and biodegradability, significantly reducing environmental impact over concrete. Concrete, while durable with a service life often exceeding 50 years, presents challenges at end-of-life due to energy-intensive recycling processes and limited biodegradability, resulting in higher embodied carbon. The longevity of living materials can be enhanced with proper treatments, and at end-of-life, they offer composting or repurposing options that align with circular economy principles, contrasting with the substantial landfill or downcycled aggregate utilization associated with concrete waste.

Innovations in Living Building Materials

Innovations in living building materials, such as mycelium-based composites and bio-cement, offer sustainable alternatives to traditional concrete by reducing carbon emissions and enhancing biodegradability. These materials harness natural processes and microorganisms to self-heal and improve insulation properties, contributing to energy-efficient construction. Emerging technologies focus on scalability and durability, enabling living materials to meet structural requirements while promoting environmental benefits over conventional concrete.

Cost Analysis and Economic Feasibility

Living building materials, such as mycelium-based composites and bio-bricks, generally have higher upfront costs compared to traditional concrete due to limited production scale and emerging technology. However, their potential for reduced environmental impact and lower lifecycle expenses, including energy savings and durability, can enhance long-term economic feasibility. Concrete remains more cost-effective for large-scale projects due to established supply chains and economies of scale, but rising carbon taxes and sustainability regulations are shifting economic incentives in favor of living building materials.

Regulatory Challenges and Standardization

Living building materials face significant regulatory challenges due to their innovative nature and lack of established testing protocols, resulting in limited building code acceptance compared to traditional concrete. Standardization efforts for living materials are still in early stages, complicating their widespread adoption and certification processes. Concrete benefits from decades of standardized regulations and well-defined performance criteria, enabling easier integration into construction projects worldwide.

Future Prospects for Sustainable Construction Materials

Living building materials, such as self-healing bio-concrete and mycelium-based composites, offer significant potential to reduce carbon footprints and enhance durability in sustainable construction. Unlike traditional concrete, which contributes to approximately 8% of global CO2 emissions, these innovative materials can absorb carbon and improve environmental resilience. Research and development in bioengineered materials are accelerating, suggesting a future where sustainable construction prioritizes renewable, eco-friendly alternatives over conventional cement-based products.

Biogenic construction

Biogenic construction materials, derived from sustainable organic sources like mycelium and algae, offer environmentally friendly, carbon-sequestering alternatives to traditional concrete, reducing emissions and enhancing building sustainability.

Mycelium composites

Mycelium composites, as sustainable and biodegradable alternatives to concrete, offer enhanced insulation, reduced carbon footprint, and regenerative growth properties for eco-friendly building materials.

Calcite precipitation

Living building materials enhance structural durability by promoting Calcite precipitation, which naturally strengthens concrete through biomineralization processes.

Microbially induced calcite

Microbially induced calcite precipitation (MICP) in living building materials offers sustainable, self-healing, and carbon-negative alternatives to traditional concrete, reducing environmental impact and enhancing durability.

Carbon-negative materials

Living building materials such as mycelium insulation and biochar composites offer carbon-negative alternatives to conventional concrete by sequestering CO2 during production and reducing overall emissions in construction.

Self-healing bio-cement

Self-healing bio-cement, a living building material, enhances durability and sustainability by autonomously repairing cracks, reducing maintenance costs and extending the lifespan of concrete structures.

Embodied carbon

Living building materials like timber and hempcrete significantly reduce embodied carbon by storing CO2, whereas concrete production emits high levels of embodied carbon due to cement manufacturing.

Algal biopolymers

Algal biopolymers in living building materials offer sustainable alternatives to concrete by enhancing biodegradability, reducing carbon emissions, and improving thermal insulation.

Green geopolymer

Green geopolymer, a sustainable alternative to concrete, reduces carbon emissions by utilizing industrial waste and natural materials, while enhancing durability and thermal performance in building applications.

Bio-bricks

Bio-bricks, made from organic waste and microorganisms, offer a sustainable alternative to concrete by reducing carbon emissions and enhancing biodegradability in building materials.

living building materials vs concrete Infographic

njnir.com

njnir.com