Lead-free solder enhances environmental safety by eliminating toxic lead emissions commonly associated with traditional solder, reducing soil and water contamination risks. It offers improved compliance with global regulations such as RoHS, promoting sustainable manufacturing practices in electronic assembly. Despite higher melting points, advancements in lead-free solder formulations maintain reliable joint strength and electrical conductivity, supporting long-term device performance.

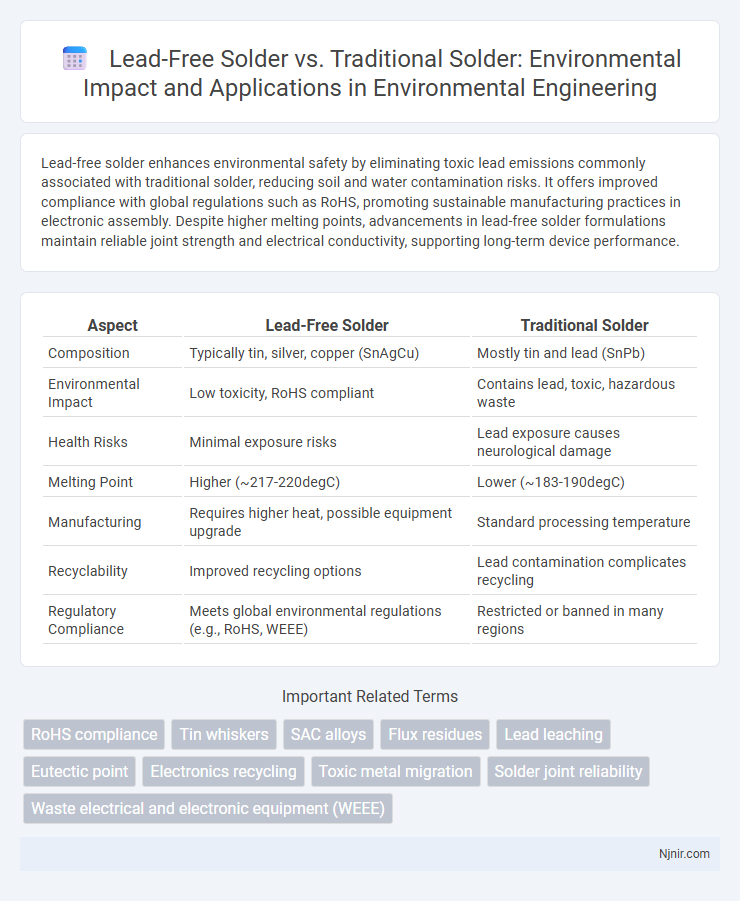

Table of Comparison

| Aspect | Lead-Free Solder | Traditional Solder |

|---|---|---|

| Composition | Typically tin, silver, copper (SnAgCu) | Mostly tin and lead (SnPb) |

| Environmental Impact | Low toxicity, RoHS compliant | Contains lead, toxic, hazardous waste |

| Health Risks | Minimal exposure risks | Lead exposure causes neurological damage |

| Melting Point | Higher (~217-220degC) | Lower (~183-190degC) |

| Manufacturing | Requires higher heat, possible equipment upgrade | Standard processing temperature |

| Recyclability | Improved recycling options | Lead contamination complicates recycling |

| Regulatory Compliance | Meets global environmental regulations (e.g., RoHS, WEEE) | Restricted or banned in many regions |

Introduction to Soldering in Environmental Engineering

Lead-free solder, primarily composed of tin, silver, and copper, offers a safer alternative to traditional lead-based solder, reducing toxic waste and environmental contamination in engineering applications. Its adoption in environmental engineering projects supports compliance with stringent regulations like the Restriction of Hazardous Substances (RoHS) Directive, promoting sustainable manufacturing processes. The performance characteristics of lead-free solder, including higher melting points and improved corrosion resistance, enhance reliability in critical infrastructure while minimizing ecological impact.

Composition: Lead-Free vs. Traditional Solder

Lead-free solder primarily consists of a tin (Sn) base alloyed with metals like silver (Ag), copper (Cu), and sometimes bismuth (Bi) to enhance mechanical properties and melting points, aligning with RoHS regulations. Traditional solder usually contains a mixture of tin and lead (Pb), commonly in a 60/40 or 63/37 ratio, offering a lower melting temperature and excellent wettability for efficient electronic assembly. The absence of lead in lead-free solder reduces toxicity but often requires higher reflow temperatures and impacts solder joint reliability due to differing metallurgical characteristics.

Environmental Impact of Lead-Containing Solder

Lead-containing solder poses significant environmental risks due to the toxic nature of lead, which can contaminate soil and water sources, leading to bioaccumulation in wildlife and humans. Lead-free solder, often composed of tin, silver, and copper, reduces these hazards by eliminating lead, thereby minimizing hazardous waste and promoting safer recycling processes. Regulations such as the EU's Restriction of Hazardous Substances (RoHS) Directive restrict lead use, driving industry adoption of lead-free alternatives to protect ecosystems and public health.

Regulatory Framework and Compliance Standards

Lead-free solder complies with international regulatory frameworks such as RoHS (Restriction of Hazardous Substances Directive), which limits the use of hazardous materials like lead in electronic components to reduce environmental and health risks. Traditional solder, containing up to 40% lead, faces restrictions and is increasingly phased out in consumer electronics to meet these global compliance standards. Manufacturers adopting lead-free solder align with EU, China, and California Proposition 65 regulations, ensuring safer and eco-friendly electronic assemblies.

Health Risks Associated with Lead Exposure

Lead-free solder eliminates the health risks associated with lead exposure, which include neurotoxicity, developmental delays, and kidney damage. Traditional solder contains lead, posing hazards through inhalation of fumes and skin contact during soldering processes. Transitioning to lead-free solder significantly reduces occupational and environmental lead contamination, promoting safer working conditions.

Performance and Reliability of Lead-Free Solder

Lead-free solder offers improved environmental compatibility but generally exhibits higher melting points and increased brittleness compared to traditional lead-based solder, impacting thermal and mechanical performance. Advances in lead-free alloy formulations, such as SAC305 (tin-silver-copper), have enhanced its reliability by reducing issues like tin whisker growth and improving joint strength under thermal cycling. Ongoing research demonstrates that, while lead-free solder joints may show slightly different failure modes, their long-term reliability in electronic assemblies meets industry standards for most consumer and industrial applications.

Cost Analysis: Lead-Free vs. Traditional Solder

Lead-free solder typically incurs higher material costs due to the use of expensive metals such as silver, bismuth, or copper, compared to the more affordable tin-lead alloys in traditional solder. Manufacturing processes may also require higher temperatures and longer reflow times, increasing energy consumption and equipment wear, which affects overall production expenses. Despite initial costs, lead-free solder aligns with environmental regulations and reduces hazardous waste disposal fees, potentially lowering long-term financial liabilities.

Waste Management and Recycling Challenges

Lead-free solder poses significant challenges in waste management and recycling due to its higher melting point and different chemical composition compared to traditional tin-lead solder. Electronic waste containing lead-free solder often requires specialized processes to separate and recover valuable metals, increasing recycling costs and complexity. Traditional solder, with its established recycling protocols, allows for more straightforward metal recovery, but its lead content raises environmental and health concerns during disposal and recycling.

Case Studies in Sustainable Soldering Practices

Case studies in sustainable soldering practices reveal that lead-free solder significantly reduces environmental toxicity compared to traditional tin-lead solder, aligning with regulations such as RoHS. Research conducted by the Electronics Sustainability Consortium highlights improved air quality and reduced hazardous waste generation in manufacturing facilities adopting lead-free alloys like SAC305 (tin-silver-copper). Further analysis shows that although lead-free solder may initially increase energy consumption due to higher melting points, long-term benefits include enhanced recyclability and compliance with global environmental standards.

Future Trends in Eco-Friendly Solder Materials

Lead-free solder is rapidly advancing with enhanced thermal and mechanical properties to meet stringent environmental regulations, reducing lead toxicity in electronics manufacturing. Emerging eco-friendly solder materials incorporate bismuth, silver, and copper alloys, which improve reliability and reduce environmental impact without compromising performance. Future trends emphasize biodegradable fluxes and energy-efficient soldering processes, aligning with global sustainability goals in electronic assembly.

RoHS compliance

Lead-free solder, compliant with RoHS regulations, eliminates hazardous lead content, ensuring safer electronics manufacturing compared to traditional lead-based solder.

Tin whiskers

Lead-free solder increases the risk of tin whisker growth compared to traditional leaded solder, potentially causing short circuits and reliability issues in electronic components.

SAC alloys

SAC alloys in lead-free solder outperform traditional tin-lead solder by offering higher melting points, improved mechanical strength, and better thermal fatigue resistance for modern electronics.

Flux residues

Lead-free solder typically produces more corrosive flux residues than traditional solder, requiring thorough cleaning to prevent long-term circuit damage.

Lead leaching

Lead-free solder significantly reduces the risk of lead leaching into the environment and products compared to traditional lead-based solder, enhancing safety and compliance with RoHS regulations.

Eutectic point

Lead-free solder typically has a higher eutectic point, around 217degC for Sn-Ag-Cu alloys, compared to traditional lead-based solder's eutectic point of 183degC for Sn-Pb alloys, affecting melting behavior and thermal profiles in electronics manufacturing.

Electronics recycling

Lead-free solder enhances electronics recycling by reducing toxic waste and enabling safer material recovery compared to traditional lead-based solder.

Toxic metal migration

Lead-free solder significantly reduces toxic metal migration compared to traditional lead-based solder, minimizing environmental contamination and health risks associated with lead exposure.

Solder joint reliability

Lead-free solder typically offers lower solder joint reliability compared to traditional leaded solder due to higher melting temperatures and increased susceptibility to brittleness and thermal fatigue.

Waste electrical and electronic equipment (WEEE)

Lead-free solder reduces toxic waste in Waste Electrical and Electronic Equipment (WEEE) recycling compared to traditional lead-based solder, minimizing environmental contamination and improving compliance with RoHS regulations.

lead-free solder vs traditional solder Infographic

njnir.com

njnir.com