Zero liquid discharge (ZLD) systems maximize water reuse by eliminating wastewater discharge through advanced treatment and evaporation techniques, significantly reducing environmental pollution. Conventional effluent treatment relies on treating wastewater to meet regulatory standards before discharge, often resulting in partial pollutant removal and potential ecological risks. Employing ZLD enhances sustainability by ensuring minimal environmental impact and promoting resource recovery.

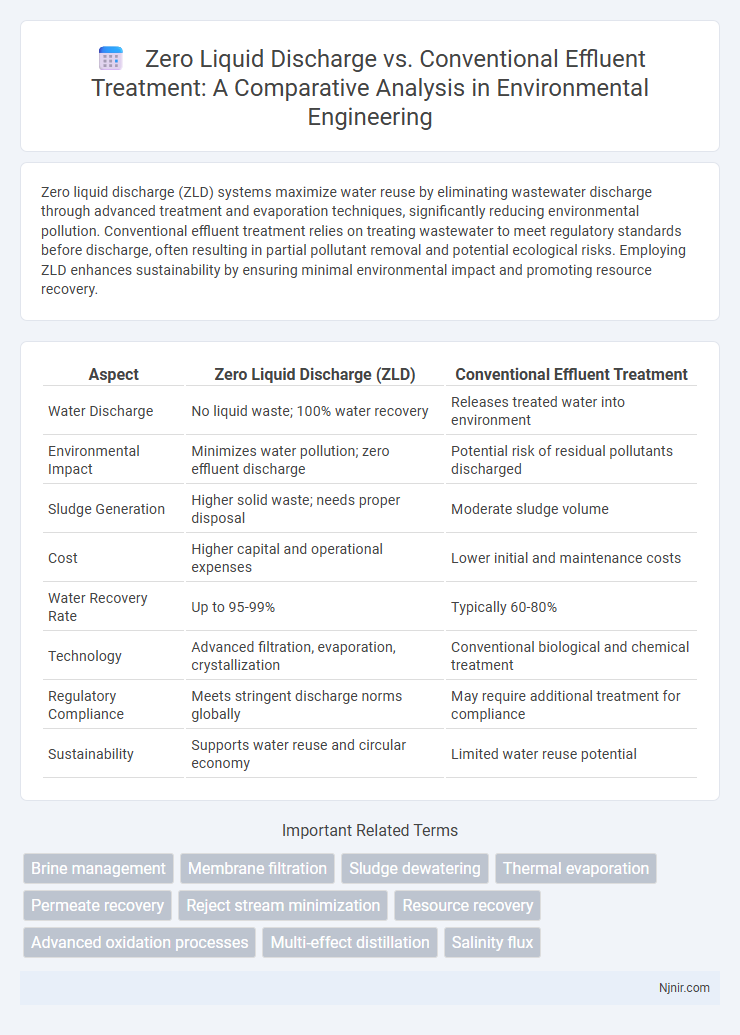

Table of Comparison

| Aspect | Zero Liquid Discharge (ZLD) | Conventional Effluent Treatment |

|---|---|---|

| Water Discharge | No liquid waste; 100% water recovery | Releases treated water into environment |

| Environmental Impact | Minimizes water pollution; zero effluent discharge | Potential risk of residual pollutants discharged |

| Sludge Generation | Higher solid waste; needs proper disposal | Moderate sludge volume |

| Cost | Higher capital and operational expenses | Lower initial and maintenance costs |

| Water Recovery Rate | Up to 95-99% | Typically 60-80% |

| Technology | Advanced filtration, evaporation, crystallization | Conventional biological and chemical treatment |

| Regulatory Compliance | Meets stringent discharge norms globally | May require additional treatment for compliance |

| Sustainability | Supports water reuse and circular economy | Limited water reuse potential |

Introduction to Effluent Management in Environmental Engineering

Zero Liquid Discharge (ZLD) is an advanced effluent management technique designed to eliminate all liquid waste from industrial processes, ensuring no discharge into the environment, which significantly reduces water pollution and conserves resources. Conventional effluent treatment typically involves primary, secondary, and tertiary treatment stages to reduce contaminants before releasing treated water, but it often results in residual liquid discharge that may still impact aquatic ecosystems. In environmental engineering, understanding the distinction between ZLD's complete recycling and reuse of wastewater versus conventional methods' partial treatment is crucial for sustainable water resource management and regulatory compliance.

Overview of Zero Liquid Discharge (ZLD) Technology

Zero Liquid Discharge (ZLD) technology achieves complete elimination of liquid waste by recovering and reusing all water from industrial effluents, minimizing environmental pollution. Unlike conventional effluent treatment that partially treats wastewater and discharges treated water, ZLD employs advanced processes like evaporation, crystallization, and membrane filtration to extract salts and solids, ensuring zero discharge. This technology is crucial for industries facing stringent regulatory standards and water scarcity challenges, enhancing sustainability and resource efficiency.

Fundamentals of Conventional Effluent Treatment Systems

Conventional effluent treatment systems primarily rely on physical, chemical, and biological processes to remove contaminants from wastewater, including sedimentation, aeration, and biodegradation. These systems typically discharge treated water back into the environment, meeting regulatory standards but often leaving residual pollutants or requiring further dilution. The core fundamentals address pollutant reduction through activated sludge, chemical precipitation, and filtration, focusing on minimizing toxicity rather than achieving complete water reuse.

Key Differences Between ZLD and Conventional Methods

Zero Liquid Discharge (ZLD) systems achieve complete elimination of liquid waste by recovering and recycling all wastewater, whereas conventional effluent treatment typically involves treating wastewater to meet discharge standards without total elimination. ZLD incorporates advanced technologies like evaporation and crystallization, driving up operational complexity and costs compared to the simpler biological and physico-chemical processes in conventional methods. The primary benefit of ZLD lies in its environmental compliance and water conservation, while conventional treatment focuses more on reducing pollutant loads to comply with regulatory limits.

Water Recovery and Resource Optimization

Zero Liquid Discharge (ZLD) systems achieve nearly 100% water recovery by recycling and reusing wastewater through advanced treatment technologies like reverse osmosis and evaporation, significantly reducing freshwater consumption. Conventional effluent treatment typically recovers less than 70% of water, leading to higher discharge volumes and increased environmental impact. ZLD optimizes resource utilization by converting waste brine into reusable solids or chemicals, promoting sustainable water management and minimizing landfill waste.

Environmental Impact and Compliance

Zero liquid discharge (ZLD) systems minimize environmental impact by eliminating wastewater discharge, reducing water pollution, and promoting water reuse, which supports stringent environmental regulations and sustainability goals. Conventional effluent treatment plants (ETPs) primarily focus on reducing pollutant levels but still discharge treated water, potentially impacting aquatic ecosystems and facing stricter regulatory limits on effluent quality. Compliance with environmental standards is more robust in ZLD systems due to complete recovery and recycle of wastewater, making them preferable for industries in water-scarce regions or with high regulatory scrutiny.

Operational Costs and Economic Considerations

Zero liquid discharge (ZLD) systems involve higher initial capital expenditure and increased operational costs due to complex treatment stages such as evaporation and crystallization, compared to conventional effluent treatment plants that rely on biological and chemical processes with relatively lower energy consumption. However, ZLD offers economic benefits through water recovery, reduced environmental compliance penalties, and potential reuse of salts and other byproducts, which can offset higher operational expenses over time. Conventional systems may incur ongoing costs related to sludge disposal, discharge fees, and potential environmental fines, making ZLD economically viable in regions with strict discharge regulations and water scarcity.

Technological Advancements in Effluent Treatment

Zero Liquid Discharge (ZLD) technology leverages advanced membrane filtration, evaporation, and crystallization techniques to achieve near-complete water recovery and minimal waste generation, surpassing conventional effluent treatment methods that primarily rely on biological and chemical processes. Innovations in ZLD systems incorporate energy-efficient thermal designs and automated control systems for optimized resource utilization and reduced operational costs. Enhanced monitoring technologies and integration of artificial intelligence further improve process stability, ensuring compliance with stringent environmental regulations and promoting sustainable water management.

Implementation Challenges and Solutions

Zero Liquid Discharge (ZLD) systems face implementation challenges such as high capital costs, complex operation, and the need for advanced technology to achieve near-complete water recovery. Conventional effluent treatment processes struggle with insufficient pollutant removal and generating secondary waste, leading to regulatory non-compliance risks. Solutions for ZLD include adopting modular system designs, integrating energy-efficient technologies, and utilizing real-time monitoring to optimize performance and reduce operational complexity.

Future Trends in Industrial Effluent Management

Future trends in industrial effluent management emphasize the shift from conventional effluent treatment processes to zero liquid discharge (ZLD) systems, driven by stricter environmental regulations and the need for sustainable water use. Innovations in membrane technology, advanced crystallizers, and energy-efficient evaporators are enhancing ZLD feasibility by minimizing waste and enabling complete water reuse. The integration of digital monitoring and automation further optimizes ZLD operations, supporting industries in meeting zero discharge mandates and reducing their environmental footprint.

Brine management

Zero liquid discharge technology eliminates brine disposal by recovering all water and converting remaining solids into reusable byproducts, whereas conventional effluent treatment typically discharges concentrated brine into the environment, posing higher ecological risks.

Membrane filtration

Zero liquid discharge systems utilize advanced membrane filtration techniques such as reverse osmosis and ultrafiltration to achieve near-complete water recovery and eliminate liquid waste, whereas conventional effluent treatment relies primarily on biological and chemical processes with limited membrane integration and typically discharges treated water.

Sludge dewatering

Zero liquid discharge systems significantly reduce sludge volume and enhance dewatering efficiency compared to conventional effluent treatment by recycling process water and concentrating solids.

Thermal evaporation

Zero liquid discharge (ZLD) systems utilize thermal evaporation to completely eliminate liquid waste by converting effluent into solid residues and reusable water, whereas conventional effluent treatment primarily reduces contaminants without fully preventing liquid discharge.

Permeate recovery

Zero liquid discharge achieves near 100% permeate recovery by recycling all treated water, whereas conventional effluent treatment typically recovers only 70-80%, resulting in significant wastewater discharge.

Reject stream minimization

Zero liquid discharge systems minimize reject streams by recycling and reusing all wastewater, contrasting with conventional effluent treatment that often generates significant liquid waste requiring disposal.

Resource recovery

Zero liquid discharge systems maximize resource recovery by recycling nearly 100% of water and extracting valuable byproducts, outperforming conventional effluent treatment which typically prioritizes pollutant removal over resource reuse.

Advanced oxidation processes

Advanced oxidation processes in zero liquid discharge systems achieve superior contaminant degradation and water recovery compared to conventional effluent treatment methods by generating highly reactive radicals that break down persistent organic pollutants.

Multi-effect distillation

Multi-effect distillation in zero liquid discharge systems recovers up to 98% water from industrial effluents, reducing wastewater volume significantly compared to conventional effluent treatment methods.

Salinity flux

Zero liquid discharge systems minimize salinity flux by completely recycling wastewater and eliminating saline discharge, whereas conventional effluent treatment often releases brine or saline effluent, contributing to higher environmental salinity flux.

zero liquid discharge vs conventional effluent treatment Infographic

njnir.com

njnir.com