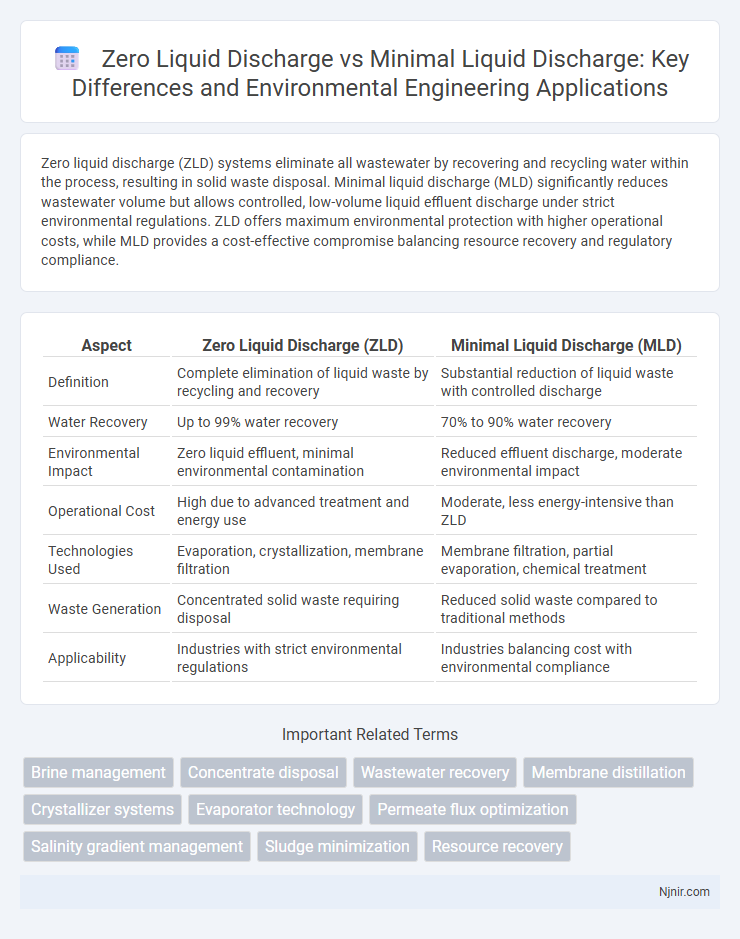

Zero liquid discharge (ZLD) systems eliminate all wastewater by recovering and recycling water within the process, resulting in solid waste disposal. Minimal liquid discharge (MLD) significantly reduces wastewater volume but allows controlled, low-volume liquid effluent discharge under strict environmental regulations. ZLD offers maximum environmental protection with higher operational costs, while MLD provides a cost-effective compromise balancing resource recovery and regulatory compliance.

Table of Comparison

| Aspect | Zero Liquid Discharge (ZLD) | Minimal Liquid Discharge (MLD) |

|---|---|---|

| Definition | Complete elimination of liquid waste by recycling and recovery | Substantial reduction of liquid waste with controlled discharge |

| Water Recovery | Up to 99% water recovery | 70% to 90% water recovery |

| Environmental Impact | Zero liquid effluent, minimal environmental contamination | Reduced effluent discharge, moderate environmental impact |

| Operational Cost | High due to advanced treatment and energy use | Moderate, less energy-intensive than ZLD |

| Technologies Used | Evaporation, crystallization, membrane filtration | Membrane filtration, partial evaporation, chemical treatment |

| Waste Generation | Concentrated solid waste requiring disposal | Reduced solid waste compared to traditional methods |

| Applicability | Industries with strict environmental regulations | Industries balancing cost with environmental compliance |

Introduction to Zero Liquid Discharge (ZLD) and Minimal Liquid Discharge (MLD)

Zero Liquid Discharge (ZLD) is an advanced wastewater treatment process designed to eliminate all liquid waste from a facility, recovering and recycling nearly 100% of water, which minimizes environmental impact and conserves resources. Minimal Liquid Discharge (MLD) reduces wastewater volume significantly but allows a controlled, minimal discharge that meets regulatory standards, balancing operational costs with environmental compliance. Both ZLD and MLD are critical in industries such as power generation, textiles, and chemicals, where water reuse and zero-contamination discharge are increasingly mandated.

Key Principles and Definitions of ZLD and MLD

Zero Liquid Discharge (ZLD) is a wastewater management process that aims to eliminate all liquid waste by recovering and reusing water through advanced treatment technologies, producing solid residues instead of liquid effluents. Minimal Liquid Discharge (MLD) reduces liquid waste to a minimal volume by concentrating and recycling most of the wastewater, allowing for a small, controlled discharge that meets environmental standards. Both ZLD and MLD prioritize water conservation and pollution control but differ in discharge policies, with ZLD targeting zero effluent release and MLD accepting limited discharge to balance operational and economic feasibility.

Technological Processes in ZLD and MLD Systems

Zero Liquid Discharge (ZLD) systems employ advanced evaporation and crystallization processes to recover nearly all water from wastewater, producing solid residues and eliminating liquid discharge entirely. Minimal Liquid Discharge (MLD) uses membrane filtration and selective evaporation to reduce liquid effluent volume substantially while allowing controlled discharge within regulatory limits. Both technologies integrate thermal and membrane-based methods, but ZLD emphasizes complete water recovery, whereas MLD balances water reuse with minimized effluent release.

Comparative Analysis: ZLD vs. MLD Efficiency

Zero Liquid Discharge (ZLD) systems achieve near-total elimination of liquid waste by recovering almost all water through advanced processes like multiple-effect evaporators and crystallizers, resulting in solid waste byproducts. Minimal Liquid Discharge (MLD) systems focus on significantly reducing liquid effluent volumes but still discharge a controlled, minimal amount of treated water, allowing for lower energy consumption and operational costs compared to ZLD. Efficiency comparisons show that ZLD maximizes water recovery and environmental compliance but at higher capital and energy expenditures, while MLD balances water reuse with cost-effectiveness, making it suitable for facilities with moderate discharge regulations.

Environmental Impact of ZLD and MLD Approaches

Zero Liquid Discharge (ZLD) systems eliminate all liquid waste by recycling and recovering water, significantly reducing freshwater consumption and preventing harmful effluents from polluting water bodies. Minimal Liquid Discharge (MLD) strategies reduce liquid waste by concentrating effluents but still discharge minimal amounts, which can contain pollutants impacting aquatic ecosystems if not managed properly. Compared to MLD, ZLD offers superior environmental protection by completely avoiding liquid effluent release, supporting sustainable water management and minimizing ecological risks.

Economic Considerations: Cost Comparison Between ZLD and MLD

Zero Liquid Discharge (ZLD) systems have significantly higher capital and operational costs compared to Minimal Liquid Discharge (MLD) due to advanced treatment technologies like multiple-effect evaporators and crystallizers, leading to increased energy consumption and maintenance expenses. MLD offers a cost-effective alternative by allowing a controlled discharge of treated wastewater, reducing investment and operational demands while still meeting environmental compliance. Industries must weigh the economic trade-offs between the stringent pollution control of ZLD and the lower costs and flexibility of MLD when selecting wastewater management strategies.

Regulatory Drivers and Compliance for ZLD and MLD

Regulatory drivers for Zero Liquid Discharge (ZLD) focus on stringent effluent standards and zero discharge mandates enforced by environmental agencies to prevent water pollution and ensure resource sustainability. Minimal Liquid Discharge (MLD) compliance aligns with regulations that permit limited effluent release under strict quality parameters, aiming to reduce water consumption while meeting statutory limits. Industries adopt ZLD and MLD systems to achieve compliance with discharge norms such as the Clean Water Act in the U.S. and the Water Framework Directive in the EU, balancing operational costs with regulatory adherence.

Operational Challenges in Implementing ZLD and MLD

Implementing Zero Liquid Discharge (ZLD) systems presents operational challenges such as high energy consumption, complex maintenance requirements, and difficulty in managing concentrated brine byproducts. Minimal Liquid Discharge (MLD) systems face challenges in balancing reduced water discharge with partial waste handling, necessitating advanced treatment technologies to prevent environmental impact. Both approaches require robust monitoring and control systems to ensure compliance with stringent environmental regulations while maintaining operational efficiency.

Case Studies: Industry Applications of ZLD and MLD

Case studies reveal that Zero Liquid Discharge (ZLD) is extensively applied in textile, chemical, and power plants to achieve near-complete wastewater recycling, significantly reducing environmental impact and regulatory penalties. Minimal Liquid Discharge (MLD) finds traction in industries like oil refining and food processing where partial water recovery balances operational costs with sustainability goals. Comparative analysis shows ZLD offers stringent compliance benefits, while MLD provides cost-effective wastewater treatment adaptable to fluctuating feedwater quality.

Future Trends and Innovations in Liquid Discharge Management

Future trends in liquid discharge management emphasize advanced membrane technologies and integrated treatment systems that enhance water recovery rates beyond 95%, supporting zero liquid discharge (ZLD) objectives. Innovations in energy-efficient evaporation and crystallization processes reduce operational costs, making minimal liquid discharge (MLD) systems more economically viable for industries aiming to minimize environmental impact. Digital monitoring and AI-driven process optimization further enable real-time management of discharge parameters, ensuring compliance with increasingly stringent environmental regulations.

Brine management

Zero liquid discharge systems achieve complete brine recovery and reuse by eliminating all liquid effluents, while minimal liquid discharge systems reduce brine volume significantly but still produce a controlled concentration of liquid waste for easier management.

Concentrate disposal

Zero liquid discharge eliminates concentrate disposal by recycling all wastewater, whereas minimal liquid discharge reduces concentrate volume but requires controlled disposal methods.

Wastewater recovery

Zero liquid discharge achieves 100% wastewater recovery by eliminating liquid waste, whereas minimal liquid discharge reduces liquid waste volume but allows limited effluent discharge.

Membrane distillation

Membrane distillation enhances zero liquid discharge systems by enabling efficient separation of contaminants and water recovery, whereas minimal liquid discharge processes using membrane distillation focus on reducing brine volume with manageable liquid waste output.

Crystallizer systems

Zero Liquid Discharge crystallizer systems achieve complete water recycling by converting all wastewater into solid salts, whereas Minimal Liquid Discharge crystallizers reduce waste volume significantly but still discharge a small liquid effluent.

Evaporator technology

Evaporator technology in zero liquid discharge (ZLD) systems enables complete recovery of water by concentrating brine to solids, while minimal liquid discharge (MLD) uses similar evaporators but allows a controlled volume of liquid waste, balancing operational cost and environmental impact.

Permeate flux optimization

Zero liquid discharge systems maximize permeate flux through advanced membrane technologies and thorough contaminant rejection, whereas minimal liquid discharge prioritizes permeate flux optimization by balancing recovery rates with manageable brine volumes to reduce wastewater disposal.

Salinity gradient management

Zero liquid discharge achieves complete salinity gradient management by recycling all wastewater, whereas minimal liquid discharge reduces effluent volume but requires additional treatment to control salinity levels.

Sludge minimization

Zero liquid discharge (ZLD) systems achieve greater sludge minimization compared to minimal liquid discharge (MLD) by maximizing water recovery and recycling while concentrating and solidifying residual waste to reduce sludge volume.

Resource recovery

Zero liquid discharge maximizes resource recovery by completely eliminating liquid waste through advanced treatment processes, while minimal liquid discharge reduces waste volume but allows controlled liquid effluent release, balancing recovery efficiency with operational cost.

zero liquid discharge vs minimal liquid discharge Infographic

njnir.com

njnir.com