Biodegradable plastics break down naturally by microorganisms over time but may leave behind microplastics and residues, whereas compostable plastics decompose fully into non-toxic components within a specific timeframe under industrial composting conditions. Compostable plastics require regulated environments with controlled temperature, humidity, and microbial activity to achieve complete degradation, ensuring minimal environmental impact. Understanding the distinctions between these materials helps improve waste management strategies and reduces plastic pollution in ecosystems.

Table of Comparison

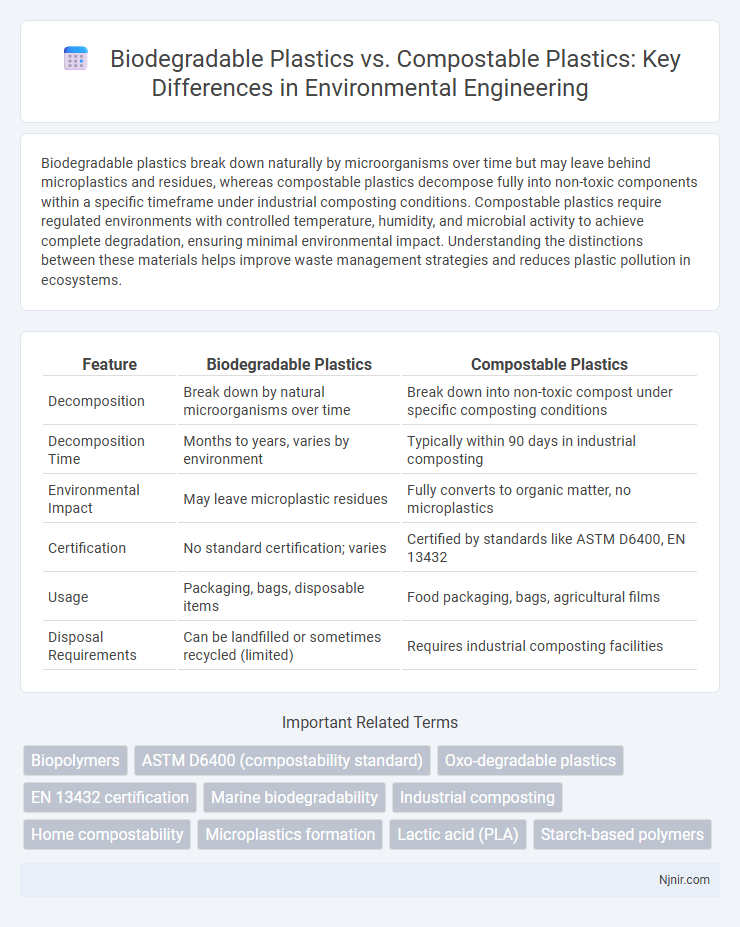

| Feature | Biodegradable Plastics | Compostable Plastics |

|---|---|---|

| Decomposition | Break down by natural microorganisms over time | Break down into non-toxic compost under specific composting conditions |

| Decomposition Time | Months to years, varies by environment | Typically within 90 days in industrial composting |

| Environmental Impact | May leave microplastic residues | Fully converts to organic matter, no microplastics |

| Certification | No standard certification; varies | Certified by standards like ASTM D6400, EN 13432 |

| Usage | Packaging, bags, disposable items | Food packaging, bags, agricultural films |

| Disposal Requirements | Can be landfilled or sometimes recycled (limited) | Requires industrial composting facilities |

Introduction to Biodegradable and Compostable Plastics

Biodegradable plastics break down naturally through microbial activity into water, carbon dioxide, and biomass under various environmental conditions, though the time frame and completeness vary. Compostable plastics are a subset of biodegradable plastics designed to decompose within industrial composting settings, meeting specific standards such as ASTM D6400 or EN 13432, resulting in non-toxic, nutrient-rich compost. Understanding the distinctions helps in selecting appropriate materials for sustainable waste management and environmental impact reduction.

Defining Biodegradable Plastics

Biodegradable plastics are materials designed to break down naturally through microbial activity over time, reducing environmental impact compared to traditional plastics. These plastics degrade into water, carbon dioxide, and biomass, but degradation rates and conditions vary widely depending on the polymer composition and environmental factors. Unlike compostable plastics, biodegradable plastics do not require specific industrial composting conditions to decompose.

Understanding Compostable Plastics

Compostable plastics are designed to break down completely into natural elements within a specific timeframe under industrial composting conditions, leaving no toxic residue. Unlike general biodegradable plastics that only partially decompose and may release microplastics, compostable plastics meet strict standards such as ASTM D6400 or EN 13432 for environmental safety and degradation. These plastics primarily utilize plant-based materials like polylactic acid (PLA) or starch blends, making them a sustainable choice for reducing landfill waste and supporting circular economy initiatives.

Key Differences: Biodegradable vs Compostable Plastics

Biodegradable plastics break down through microbial activity over time but may leave behind microplastics or harmful residues, whereas compostable plastics decompose into non-toxic, nutrient-rich compost within a specific timeframe under industrial composting conditions. Compostable plastics require controlled environments with precise temperature, humidity, and oxygen levels to fully degrade, while biodegradable plastics can degrade in a wider range of conditions but with less predictable results. Key differences include environmental impact, degradation speed, and standards compliance, where compostable plastics meet strict certifications like ASTM D6400 or EN 13432, unlike many biodegradable plastics.

Environmental Impact Comparison

Biodegradable plastics break down through microbial activity over varying timeframes but may leave harmful residues, whereas compostable plastics decompose fully into non-toxic components within specific industrial composting conditions. Compostable plastics offer a clearer environmental benefit by reducing landfill waste and minimizing soil and water contamination compared to some biodegradable options that degrade incompletely. The environmental impact of compostable plastics is generally lower due to their compatibility with established composting systems that support nutrient recycling and reduce greenhouse gas emissions.

Decomposition Processes and Conditions

Biodegradable plastics break down through microbial activity into water, carbon dioxide, and biomass under various environmental conditions but may leave behind microplastics if not fully degraded. Compostable plastics require specific industrial composting conditions, such as high temperature (around 58degC), humidity, and oxygen levels, to decompose completely within a set timeframe, typically 90 to 180 days. The distinct decomposition processes determine their environmental impact, as compostable plastics ensure full assimilation into organic matter, while biodegradable plastics' degradation can be slower and less predictable in natural settings.

Certification Standards and Regulations

Biodegradable plastics and compostable plastics are distinguished primarily by certification standards such as ASTM D6400 and EN 13432, which validate compostability based on specific degradation rates and environmental conditions. Biodegradable plastics may break down under variable conditions without guaranteed timelines, whereas compostable plastics must decompose completely within industrial composting facilities, leaving no toxic residues. Regulatory frameworks like the U.S. Federal Trade Commission's Green Guides and the European Union's Packaging Directive enforce labeling accuracy, ensuring consumer transparency and environmental compliance.

Challenges in Waste Management

Biodegradable plastics often fail to degrade efficiently in standard landfill conditions due to limited oxygen and microbial activity, complicating waste management systems. Compostable plastics require industrial composting facilities with precise temperature and humidity control, which are not universally available, leading to contamination in recycling streams. Both types challenge waste sorting infrastructure and create confusion among consumers, hindering effective recycling and composting processes.

Innovations and Future Trends

Biodegradable plastics are evolving with advanced enzyme formulations that accelerate breakdown in diverse environments, while compostable plastics prioritize materials like polylactic acid (PLA) for efficient decomposition in industrial composting systems. Innovations include integrating bio-based additives that enhance mechanical properties and reduce carbon footprints, alongside smart polymers that trigger degradation upon specific environmental cues. Future trends indicate a convergence of biodegradability and compostability standards to create hybrid materials optimized for circular economy applications and regulatory compliance globally.

Choosing the Sustainable Option

Biodegradable plastics break down through microbial action but may leave behind microplastics, whereas compostable plastics completely degrade into non-toxic components under specific composting conditions. Selecting compostable plastics ensures a more environmentally friendly disposal process by reducing pollution and supporting soil health. Understanding certification labels like ASTM D6400 or EN 13432 helps consumers choose truly compostable products over merely biodegradable ones.

Biopolymers

Biopolymers used in biodegradable plastics break down through microbial activity under natural conditions, while compostable plastics, often derived from biopolymers, require specific industrial composting environments to fully decompose into non-toxic components.

ASTM D6400 (compostability standard)

Biodegradable plastics break down through microbial action under various conditions, whereas compostable plastics must meet ASTM D6400 standards, ensuring complete decomposition into carbon dioxide, water, inorganic compounds, and biomass within a specific timeframe in industrial composting facilities.

Oxo-degradable plastics

Oxo-degradable plastics contain additives that accelerate fragmentation but do not fully biodegrade, unlike compostable plastics designed to break down completely into non-toxic components under composting conditions.

EN 13432 certification

EN 13432 certification ensures compostable plastics meet strict biodegradability, disintegration, and eco-toxicity criteria, distinguishing them from biodegradable plastics without standardized certification.

Marine biodegradability

Compostable plastics break down completely in marine environments within months under industrial composting conditions, whereas biodegradable plastics may fragment but often persist longer and can produce microplastics harmful to marine ecosystems.

Industrial composting

Industrial composting facilities efficiently break down compostable plastics into non-toxic, nutrient-rich compost within 90 to 180 days, whereas biodegradable plastics may only partially degrade and often require specific environmental conditions not guaranteed in these facilities.

Home compostability

Compostable plastics certified for home composting break down safely within 90 days, unlike many biodegradable plastics that may require industrial facilities or longer times to decompose effectively.

Microplastics formation

Compostable plastics break down into non-toxic organic matter without producing microplastics, whereas biodegradable plastics can fragment into harmful microplastics that persist in the environment.

Lactic acid (PLA)

Lactic acid-based polylactic acid (PLA) is a compostable plastic derived from renewable resources that breaks down fully in industrial composting conditions, unlike some biodegradable plastics which may fragment without complete biodegradation.

Starch-based polymers

Starch-based polymers in biodegradable plastics break down through microbial activity but compostable plastics require specific conditions like industrial composting facilities to fully decompose.

biodegradable plastics vs compostable plastics Infographic

njnir.com

njnir.com