Thermal desorption uses heat to volatilize contaminants from soil, enabling the extraction of pollutants that are otherwise difficult to remove. Soil vapor extraction relies on vacuum pressure to remove volatile organic compounds by extracting vapors from the soil gas phase. Thermal desorption often achieves deeper contaminant removal, while soil vapor extraction is more cost-effective and suitable for lighter, more volatile substances.

Table of Comparison

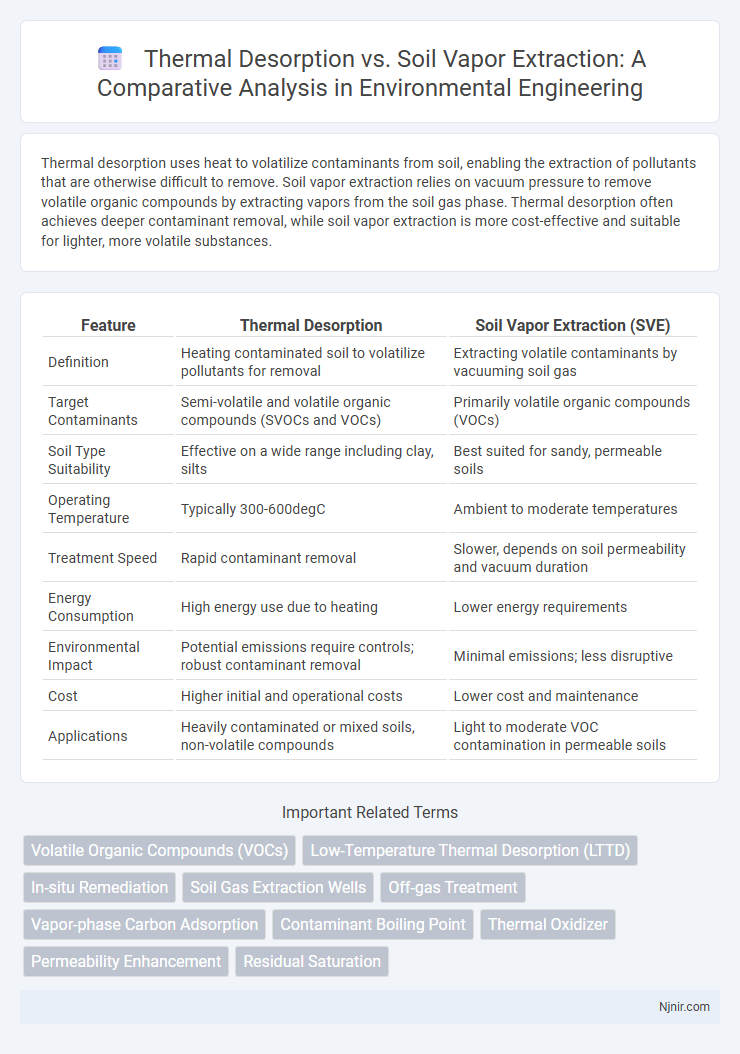

| Feature | Thermal Desorption | Soil Vapor Extraction (SVE) |

|---|---|---|

| Definition | Heating contaminated soil to volatilize pollutants for removal | Extracting volatile contaminants by vacuuming soil gas |

| Target Contaminants | Semi-volatile and volatile organic compounds (SVOCs and VOCs) | Primarily volatile organic compounds (VOCs) |

| Soil Type Suitability | Effective on a wide range including clay, silts | Best suited for sandy, permeable soils |

| Operating Temperature | Typically 300-600degC | Ambient to moderate temperatures |

| Treatment Speed | Rapid contaminant removal | Slower, depends on soil permeability and vacuum duration |

| Energy Consumption | High energy use due to heating | Lower energy requirements |

| Environmental Impact | Potential emissions require controls; robust contaminant removal | Minimal emissions; less disruptive |

| Cost | Higher initial and operational costs | Lower cost and maintenance |

| Applications | Heavily contaminated or mixed soils, non-volatile compounds | Light to moderate VOC contamination in permeable soils |

Introduction to Soil Remediation Technologies

Thermal desorption and soil vapor extraction are prominent soil remediation technologies used to treat contaminated sites by removing volatile and semi-volatile organic compounds. Thermal desorption utilizes heat to volatilize pollutants for subsequent capture or destruction, effectively treating soils with heavy contamination or complex mixtures. Soil vapor extraction, relying on vacuum systems to extract volatile contaminants from unsaturated soils, is more efficient for light to moderate hydrocarbon pollution in vadose zones.

Principles of Thermal Desorption

Thermal desorption utilizes controlled heating to volatilize organic contaminants in soil, separating pollutants from the solid matrix without combustion. It operates by raising soil temperature to a point where contaminants evaporate and can be collected or treated in a secondary system. This method contrasts with soil vapor extraction, which relies on vacuum-induced airflow to remove volatile compounds, focusing on gas-phase extraction rather than altering soil temperature directly.

Mechanisms of Soil Vapor Extraction

Soil vapor extraction (SVE) works by applying vacuum to the subsurface, inducing airflow that volatilizes and transports contaminants from soil pores to the surface for capture and treatment. This mechanism relies on the physical process of volatilization and advective mass transfer driven by changes in pressure gradients. In contrast, thermal desorption uses heat to increase contaminant volatility, significantly enhancing contaminant removal from soil particles before vapor extraction occurs.

Key Differences: Thermal Desorption vs. Soil Vapor Extraction

Thermal desorption uses high temperatures to volatilize contaminants from soil, making it effective for treating a wide range of hazardous compounds, including semi-volatile organic compounds and heavy hydrocarbons. Soil vapor extraction (SVE) relies on vacuum suction to remove volatile contaminants as gas from the soil's unsaturated zone, primarily targeting lighter hydrocarbons and volatile organic compounds. The key difference lies in thermal desorption's ability to treat more complex contaminants through heat, while SVE is limited to volatilizing and extracting more readily evaporated pollutants.

Contaminant Types Best Suited for Each Method

Thermal desorption is most effective for removing heavy hydrocarbons, polycyclic aromatic hydrocarbons (PAHs), and other semi-volatile organic compounds (SVOCs) due to its ability to heat soil and volatilize contaminants at higher temperatures. Soil vapor extraction (SVE) targets volatile organic compounds (VOCs) such as benzene, toluene, ethylbenzene, and xylene (BTEX), efficiently capturing vapors from lighter contaminants at ambient or slightly elevated temperatures. The choice between these methods depends largely on contaminant volatility and soil matrix characteristics, with thermal desorption preferred for less volatile, higher molecular weight compounds and SVE for lighter, more volatile substances.

Process Efficiency and Treatment Time

Thermal desorption achieves higher process efficiency by applying direct heat to contaminated soil, enabling rapid volatilization of pollutants and treatment times ranging from hours to days. Soil vapor extraction relies on airflow to remove volatile compounds, resulting in longer treatment durations often spanning weeks to months due to slower contaminant removal rates. The higher thermal energy input in thermal desorption accelerates contaminant desorption, making it more effective for dense or heavily polluted soils compared to soil vapor extraction.

Environmental Impacts and Safety Considerations

Thermal desorption effectively treats contaminated soils by heating them to volatilize pollutants, minimizing hazardous waste generation but requiring careful control of emissions to prevent air pollution. Soil vapor extraction (SVE) removes volatile contaminants from the subsurface using vacuum suction, which poses lower risks of thermal hazards but may lead to the dispersal of vapor-phase contaminants if not properly managed. Both methods demand strict monitoring to ensure worker safety and environmental compliance, with thermal desorption requiring additional safeguards against high-temperature exposure and potential off-gas toxicity.

Cost Comparison and Economic Feasibility

Thermal desorption typically entails higher upfront capital and operational costs due to its energy-intensive heating process, making it more expensive than soil vapor extraction (SVE) for treating contaminated soils. SVE is generally more cost-effective for volatile organic compounds (VOCs) in unsaturated soils, offering lower installation and maintenance expenses with faster remediation cycles. Economic feasibility depends on contaminant type, soil conditions, and cleanup goals, where thermal desorption excels in treating complex, high-contamination sites despite its higher cost.

Case Studies: Real-World Applications

Thermal desorption has been effectively utilized in case studies involving heavy hydrocarbon contamination at former industrial sites, achieving significant pollutant removal through heating and volatilization. Soil vapor extraction (SVE) is widely applied in real-world scenarios targeting volatile organic compounds (VOCs) in unsaturated soils, with documented success in reducing contamination levels in groundwater protection zones. Comparative analyses demonstrate that thermal desorption offers higher treatment efficiency for dense, recalcitrant contaminants, whereas SVE is cost-effective and suitable for ongoing remediation of lighter, more volatile compounds.

Future Trends in Soil Remediation Technologies

Thermal desorption and soil vapor extraction (SVE) are evolving with innovations in energy efficiency and real-time contaminant monitoring, enhancing their effectiveness in soil remediation. Advances in hybrid systems combining thermal desorption's ability to treat heavily contaminated soils with SVE's efficiency in volatile organic compound extraction are becoming prominent. Integration of AI-driven predictive modeling and sustainable energy sources is anticipated to drive future developments in these soil remediation technologies.

Volatile Organic Compounds (VOCs)

Thermal desorption effectively removes high concentrations of Volatile Organic Compounds (VOCs) from contaminated soils by heating, while soil vapor extraction primarily targets lighter VOCs through subsurface air flow and vapor removal.

Low-Temperature Thermal Desorption (LTTD)

Low-Temperature Thermal Desorption (LTTD) effectively treats contaminated soils by heating them to 90-320degC to volatilize hazardous organic compounds, unlike soil vapor extraction which primarily removes volatile contaminants through airflow without thermal treatment.

In-situ Remediation

Thermal desorption and soil vapor extraction are in-situ remediation techniques where thermal desorption uses controlled heating to volatilize contaminants from soil, while soil vapor extraction relies on vacuum extraction of vaporized pollutants from the subsurface.

Soil Gas Extraction Wells

Soil Gas Extraction Wells in thermal desorption systems enhance contaminant removal by heating soil to volatilize pollutants, while in soil vapor extraction, they primarily rely on vacuum pressure to extract volatile contaminants from unsaturated soil zones.

Off-gas Treatment

Thermal desorption requires high-temperature off-gas treatment systems to effectively capture and destroy concentrated contaminants, whereas soil vapor extraction employs lower-temperature off-gas treatment primarily using activated carbon or biofilters for dilute vapor streams.

Vapor-phase Carbon Adsorption

Vapor-phase carbon adsorption in thermal desorption systems effectively captures volatilized contaminants by adsorbing vapors onto activated carbon, offering higher efficiency and longer operational lifespan compared to soil vapor extraction methods.

Contaminant Boiling Point

Thermal desorption effectively removes contaminants with boiling points above 100degC by heating soil to volatilize pollutants, whereas soil vapor extraction primarily targets volatile contaminants with lower boiling points below 100degC.

Thermal Oxidizer

Thermal oxidizers in thermal desorption systems efficiently destroy volatile organic compounds by heating extracted soil vapors to high temperatures, providing a more complete contaminant breakdown compared to soil vapor extraction alone.

Permeability Enhancement

Thermal desorption significantly enhances soil permeability by heating contaminants to volatilize them, whereas soil vapor extraction relies on existing permeability and may require additional measures to improve vapor flow.

Residual Saturation

Thermal desorption achieves lower residual saturation of contaminants compared to soil vapor extraction by heating soil to release trapped pollutants more effectively.

thermal desorption vs soil vapor extraction Infographic

njnir.com

njnir.com