UV disinfection effectively inactivates a broad spectrum of pathogens without producing harmful disinfection byproducts, making it a safer alternative to chlorine. Unlike chlorine, which can form carcinogenic trihalomethanes, UV treatment preserves water quality and minimizes chemical residues. UV systems require less maintenance and offer rapid microbial inactivation, enhancing overall sustainability in water treatment processes.

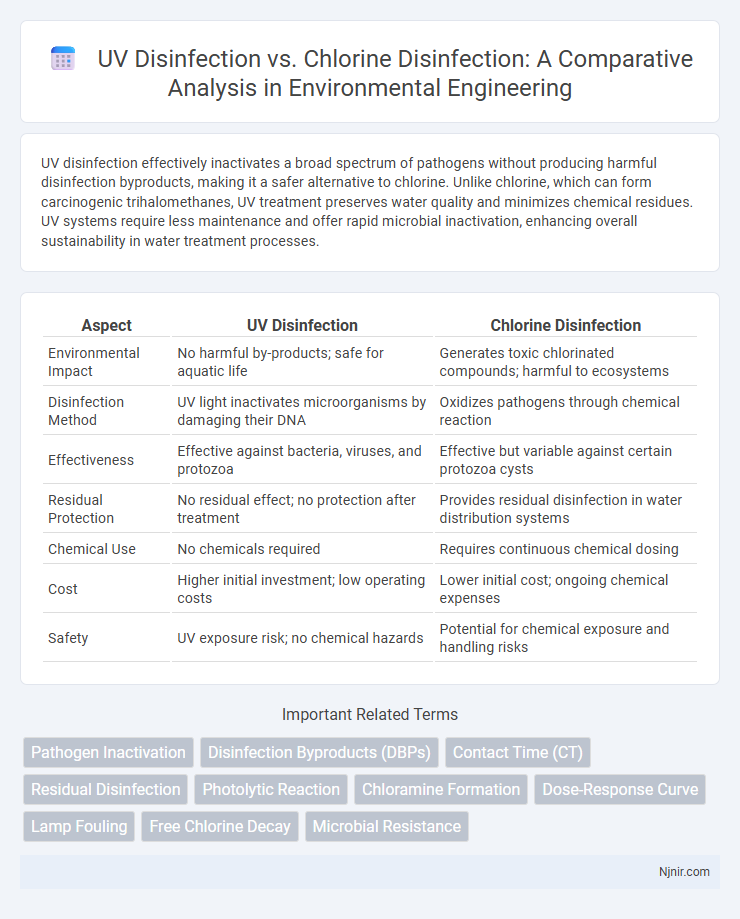

Table of Comparison

| Aspect | UV Disinfection | Chlorine Disinfection |

|---|---|---|

| Environmental Impact | No harmful by-products; safe for aquatic life | Generates toxic chlorinated compounds; harmful to ecosystems |

| Disinfection Method | UV light inactivates microorganisms by damaging their DNA | Oxidizes pathogens through chemical reaction |

| Effectiveness | Effective against bacteria, viruses, and protozoa | Effective but variable against certain protozoa cysts |

| Residual Protection | No residual effect; no protection after treatment | Provides residual disinfection in water distribution systems |

| Chemical Use | No chemicals required | Requires continuous chemical dosing |

| Cost | Higher initial investment; low operating costs | Lower initial cost; ongoing chemical expenses |

| Safety | UV exposure risk; no chemical hazards | Potential for chemical exposure and handling risks |

Overview of UV and Chlorine Disinfection Methods

UV disinfection employs ultraviolet light to inactivate microorganisms by disrupting their DNA, providing a chemical-free method effective against bacteria, viruses, and protozoa. Chlorine disinfection relies on chemical oxidation to destroy pathogens and maintain residual disinfectant levels in water distribution systems, widely used for its cost-effectiveness and long-lasting protection. Both methods play critical roles in water treatment, with UV favored for point-of-use applications and chlorine dominating large-scale municipal treatment for sustained microbial control.

Mechanisms of Action: UV Light vs Chlorine

UV disinfection works by emitting ultraviolet light that penetrates microbial cells, damaging their DNA and preventing replication, which effectively inactivates bacteria, viruses, and protozoa. Chlorine disinfection relies on chemical oxidation, where chlorine reacts with microbial cell membranes and essential enzymes, leading to cell lysis and metabolic disruption. Both methods offer pathogen control, but UV provides rapid, physical inactivation without harmful chemical byproducts, unlike chlorine which forms disinfection byproducts such as trihalomethanes.

Effectiveness Against Pathogens

UV disinfection inactivates a broad spectrum of pathogens by disrupting their DNA and RNA, making it highly effective against bacteria, viruses, and protozoa without leaving harmful residues. Chlorine disinfection works by oxidizing microbial cells, effectively killing most bacteria and viruses but may be less effective against certain protozoan cysts such as Cryptosporidium. UV systems provide rapid pathogen inactivation and reduced formation of disinfection byproducts, while chlorine offers residual protection in water distribution systems.

Environmental Impact and Byproduct Formation

UV disinfection significantly reduces environmental impact by avoiding the release of harmful chlorinated byproducts such as trihalomethanes (THMs) and haloacetic acids (HAAs), which are common in chlorine disinfection processes. Chlorine disinfection can contribute to ecological toxicity in aquatic systems due to residual chlorine and the formation of persistent disinfection byproducts (DBPs) that degrade water quality. UV systems provide an eco-friendly alternative by using ultraviolet light to inactivate pathogens without introducing chemical contaminants or residual pollutants.

Operational and Maintenance Requirements

UV disinfection systems require periodic cleaning of quartz sleeves and regular lamp replacements to maintain effective UV intensity, while chlorine disinfection demands continuous chemical dosing, monitoring, and storage of hazardous chemicals. UV systems typically have lower chemical handling risks and simpler compliance protocols but necessitate electrical power and skilled technicians for routine checks. In contrast, chlorine disinfection involves more frequent monitoring of residual chlorine levels and corrosion management in equipment, increasing overall operational complexity and safety measures.

Safety Considerations and Risks

UV disinfection offers a chemical-free method that eliminates pathogens without producing harmful byproducts, making it safer for human exposure and reducing environmental impact compared to chlorine disinfection. Chlorine disinfection involves the use of toxic chemicals that can cause skin and respiratory irritation, and its reaction with organic matter can generate carcinogenic disinfection byproducts like trihalomethanes (THMs). While UV systems require regular maintenance to ensure effective pathogen inactivation and prevent lamp degradation, chlorine poses risks of overdosing and chemical burns during handling and storage.

Cost Comparison and Economic Viability

UV disinfection systems typically have higher initial installation costs than chlorine disinfection but offer lower ongoing operational expenses due to minimal chemical requirements and reduced maintenance needs. Chlorine disinfection incurs lower upfront costs; however, continuous chemical procurement and handling increase long-term expenses, alongside potential costs related to byproduct management and safety measures. Economic viability favors UV disinfection in large-scale or long-term applications where durability and reduced chemical usage offset initial investment over time.

Regulatory Standards and Compliance

UV disinfection systems must comply with regulatory standards such as the U.S. EPA Guide Standard and Protocol for Testing Microbiological Water Purifiers, ensuring effective pathogen inactivation without harmful byproducts. Chlorine disinfection is governed by regulations like the Safe Drinking Water Act (SDWA) and must meet maximum residual disinfectant levels (MRDL) to control disinfection byproducts such as trihalomethanes (THMs) and haloacetic acids (HAAs). Both methods require routine monitoring and reporting to regulatory agencies to maintain compliance and safeguard public health in municipal and industrial water treatment applications.

Applications in Water and Wastewater Treatment

UV disinfection effectively inactivates bacteria, viruses, and protozoa in drinking water and wastewater without introducing harmful byproducts, making it ideal for municipal water treatment and advanced wastewater reuse. Chlorine disinfection remains widely used due to its residual effect, providing ongoing microbial control in distribution systems despite forming disinfection byproducts such as trihalomethanes. Both methods are integrated in water treatment plants to balance immediate pathogen inactivation and long-term microbial safety in potable water and effluent discharge.

Future Trends in Disinfection Technologies

UV disinfection is gaining traction due to its chemical-free process and effectiveness against antibiotic-resistant pathogens, aligning with increasing environmental regulations and sustainability goals. Emerging hybrid systems combining UV with advanced oxidation processes (AOP) promise enhanced pathogen control and reduction of disinfection byproducts compared to traditional chlorine methods. Innovations in LED-based UV technology offer lower energy consumption and longer lamp lifespans, driving future adoption in municipal and industrial water treatment sectors over chlorine disinfection.

Pathogen Inactivation

UV disinfection inactivates pathogens by disrupting their DNA or RNA, offering broad-spectrum effectiveness without harmful chemical residues, while chlorine disinfection kills pathogens through oxidative damage but may produce toxic byproducts and require longer contact times.

Disinfection Byproducts (DBPs)

UV disinfection produces significantly fewer harmful disinfection byproducts (DBPs) compared to chlorine disinfection, making it a safer choice for water treatment.

Contact Time (CT)

UV disinfection achieves effective microbial inactivation with significantly shorter contact time (CT) compared to chlorine disinfection, which requires prolonged CT to maintain residual effectiveness and prevent pathogen regrowth.

Residual Disinfection

UV disinfection provides effective immediate microbial inactivation but lacks residual disinfectant properties in distribution systems, whereas chlorine disinfection offers sustained residual protection to inhibit microbial regrowth and biofilm formation.

Photolytic Reaction

UV disinfection inactivates pathogens through a photolytic reaction that damages microbial DNA, offering a chemical-free alternative to chlorine disinfection, which relies on oxidative chemical reactions to kill microorganisms.

Chloramine Formation

Chlorine disinfection often leads to chloramine formation from the reaction with ammonia, whereas UV disinfection effectively inactivates pathogens without producing chloramines or harmful disinfection byproducts.

Dose-Response Curve

UV disinfection exhibits a steeper dose-response curve than chlorine disinfection, indicating more rapid microbial inactivation with increasing UV dose.

Lamp Fouling

UV disinfection efficacy decreases significantly due to lamp fouling caused by mineral deposits and biofilm accumulation, whereas chlorine disinfection maintains microbial control without such surface contamination issues.

Free Chlorine Decay

Free chlorine decay occurs rapidly in chlorine disinfection due to reactions with organic matter, whereas UV disinfection maintains water quality without chemical residue or free chlorine decay.

Microbial Resistance

UV disinfection effectively inactivates a broad spectrum of microbes without promoting microbial resistance, unlike chlorine disinfection which can lead to chlorine-resistant strains and biofilm formation.

UV Disinfection vs Chlorine Disinfection Infographic

njnir.com

njnir.com