Small modular reactors (SMRs) offer scalable power generation with enhanced safety features and the potential for cost-effective mass production, making them suitable for regional grids and industrial applications. Microreactors provide ultra-compact designs optimized for remote locations and emergency scenarios, delivering rapid deployment and minimal onsite infrastructure requirements. Both technologies advance nuclear engineering by improving flexibility and accessibility of clean energy solutions but differ primarily in size, power output, and deployment scope.

Table of Comparison

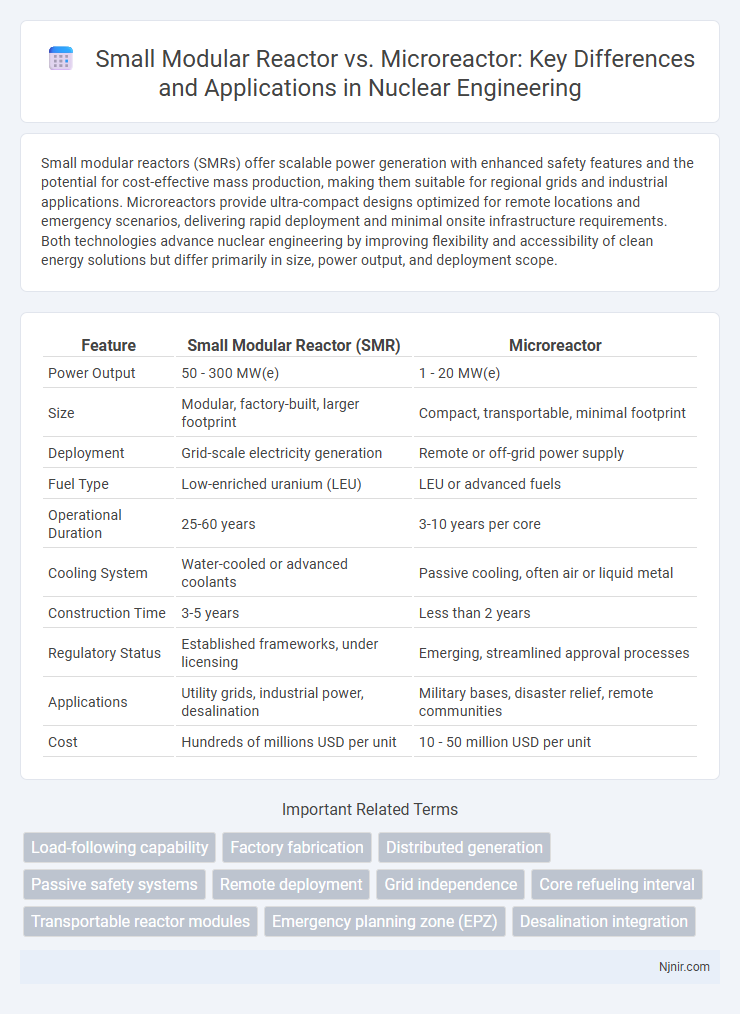

| Feature | Small Modular Reactor (SMR) | Microreactor |

|---|---|---|

| Power Output | 50 - 300 MW(e) | 1 - 20 MW(e) |

| Size | Modular, factory-built, larger footprint | Compact, transportable, minimal footprint |

| Deployment | Grid-scale electricity generation | Remote or off-grid power supply |

| Fuel Type | Low-enriched uranium (LEU) | LEU or advanced fuels |

| Operational Duration | 25-60 years | 3-10 years per core |

| Cooling System | Water-cooled or advanced coolants | Passive cooling, often air or liquid metal |

| Construction Time | 3-5 years | Less than 2 years |

| Regulatory Status | Established frameworks, under licensing | Emerging, streamlined approval processes |

| Applications | Utility grids, industrial power, desalination | Military bases, disaster relief, remote communities |

| Cost | Hundreds of millions USD per unit | 10 - 50 million USD per unit |

Introduction to Small Modular Reactors and Microreactors

Small modular reactors (SMRs) are compact nuclear power plants typically producing up to 300 MW of electricity, designed for factory fabrication and simplified installation. Microreactors are even smaller, often under 10 MW, tailored for remote locations or specialized applications with enhanced portability and rapid deployment capabilities. Both reactor types emphasize scalable, flexible, and safer nuclear energy solutions to complement traditional large-scale reactors.

Design Differences Between SMRs and Microreactors

Small modular reactors (SMRs) typically feature power outputs ranging from 50 to 300 megawatts electric (MWe) and consist of multiple modules designed for factory fabrication and on-site assembly, emphasizing scalability and ease of integration into existing grids. Microreactors operate at a much smaller scale, generally below 20 MWe, prioritizing ultra-compact designs with enhanced portability, rapid deployment, and simplified systems to support remote or off-grid applications. The fundamental design differences lie in SMRs' modular scalability for larger, distributed power generation versus microreactors' focus on minimal footprint and autonomous operation in isolated environments.

Power Output and Capacity Comparison

Small modular reactors (SMRs) typically generate between 50 and 300 megawatts electric (MWe), making them suitable for medium-scale power generation and grid integration. Microreactors, in contrast, have a significantly lower power output, generally ranging from 1 to 20 MWe, designed for remote or off-grid applications. The capacity difference highlights SMRs' role in supplementing traditional power plants, while microreactors prioritize portability and rapid deployment in localized energy needs.

Deployment Flexibility and Applications

Small modular reactors (SMRs) offer scalable energy solutions suitable for grid integration and industrial applications, with power outputs typically ranging from 50 to 300 megawatts electric (MWe). Microreactors, producing less than 10 MWe, emphasize deployment flexibility by enabling transportable and rapid setup for remote locations, military bases, and disaster relief efforts. The compact design of microreactors supports off-grid power generation and specialized applications where traditional SMRs are less practical due to size and infrastructure requirements.

Safety Features and Passive Systems

Small modular reactors (SMRs) incorporate advanced safety features such as passive cooling systems that rely on natural circulation to remove heat without external power or operator intervention, significantly reducing the risk of meltdown. Microreactors, being even smaller, emphasize inherent safety through robust containment structures and simplified designs that allow for passive shutdown and long-term cooling without active systems. Both technologies prioritize passive safety mechanisms, but microreactors excel in rapid deployment and enhanced autonomy, ensuring secure operation in remote areas or off-grid applications.

Licensing and Regulatory Pathways

Small modular reactors (SMRs) typically face established licensing processes by regulatory bodies like the U.S. Nuclear Regulatory Commission (NRC), leveraging experience from larger reactors but require detailed design certification and site-specific approvals. Microreactors, being newer and smaller, encounter evolving regulatory frameworks with experimental licensure models that emphasize expedited review to support rapid deployment and diverse applications. Both reactor types must meet stringent safety, security, and environmental standards, but microreactors benefit from adaptability in regulatory pathways that accommodate their innovative and often remote-use cases.

Economic Considerations and Cost Analysis

Small modular reactors (SMRs) generally exhibit higher upfront capital costs but benefit from economies of scale and standardized manufacturing processes that reduce per-unit costs over time, making them economically viable for larger grid applications. Microreactors feature significantly lower initial investment and shorter construction timelines, catering to niche markets with remote or limited-capacity power needs, though they typically have higher cost per megawatt-hour due to smaller output. Evaluating levelized cost of electricity (LCOE) reveals that SMRs tend to offer better cost efficiency in larger deployments, whereas microreactors provide flexible, on-demand power solutions with potentially higher operational expenses.

Fuel Types and Life Cycles

Small modular reactors (SMRs) typically use low-enriched uranium (LEU) fuel with enriched levels around 3-5%, supporting operational life cycles of 3 to 7 years before refueling is required. Microreactors often employ high-assay low-enriched uranium (HALEU) or TRISO fuel particles, enabling extended life cycles ranging from 5 to 10 years with minimal maintenance and potential for sealed operation. The choice of fuel in microreactors enhances safety and flexibility, while SMRs leverage established fuel technologies optimized for larger scale, longer-duration energy production.

Grid Integration and Off-Grid Potential

Small modular reactors (SMRs) offer scalable power generation with strong grid integration capabilities, supporting load following and enhancing grid stability through advanced control systems and higher output ranging from 50 to 300 MW. Microreactors, typically producing under 50 MW, excel in off-grid applications due to their compact size, rapid deployment, and autonomous operation, serving remote or critical infrastructure where grid access is limited or non-existent. Both technologies complement energy strategies by balancing continuous, reliable power supply with flexibility for diverse grid demands and isolated energy needs.

Future Outlook and Technological Advancements

Small modular reactors (SMRs) and microreactors both represent key advancements in nuclear technology, with SMRs offering scalable, flexible power solutions suited for grid integration, while microreactors prioritize compactness and portability for remote or specialized applications. Future outlooks emphasize SMRs' potential in decarbonizing large-scale energy grids through enhanced safety features, modular construction, and improved fuel efficiency. Microreactors advance with breakthroughs in rapid deployment, autonomous operation, and minimal waste production, targeting markets like military bases, disaster relief, and off-grid communities.

Load-following capability

Small modular reactors offer greater load-following capability with higher operational flexibility compared to microreactors, which are typically designed for stable, consistent power output in remote or off-grid locations.

Factory fabrication

Small modular reactors feature factory fabrication of standardized modules for scalable power generation, while microreactors prioritize ultra-compact, fully factory-built units enabling rapid deployment and minimal onsite assembly.

Distributed generation

Small modular reactors provide scalable, grid-compatible power ideal for distributed generation, while microreactors offer ultra-compact, low-capacity solutions optimized for remote or off-grid distributed energy applications.

Passive safety systems

Small modular reactors incorporate advanced passive safety systems utilizing natural circulation and gravity-driven mechanisms, while microreactors prioritize ultra-compact, inherently safe designs with simplified passive cooling to enhance deployment flexibility in remote locations.

Remote deployment

Small modular reactors enable efficient remote deployment with scalable power output, while microreactors offer ultra-compact, portable solutions ideal for extremely isolated locations requiring rapid setup and minimal infrastructure.

Grid independence

Small modular reactors provide scalable grid-connected power solutions, while microreactors enable compact, fully grid-independent energy supply for remote or off-grid locations.

Core refueling interval

Small modular reactors typically require refueling every 18 to 24 months, while microreactors can operate for 3 to 5 years without core refueling due to their compact, long-life core designs.

Transportable reactor modules

Small modular reactors (SMRs) typically range from 50 to 300 MW and offer scalable power for larger grids, while microreactors are compact, transportable units under 10 MW designed for rapid deployment in remote or emergency settings.

Emergency planning zone (EPZ)

Small modular reactors (SMRs) typically have an Emergency Planning Zone (EPZ) radius of 5 to 10 miles due to moderate power output, whereas microreactors, with output below 50 MW, often have significantly smaller or no formal EPZ, reflecting reduced radiological risk.

Desalination integration

Small modular reactors provide higher capacity and longer operational durations for large-scale desalination projects, while microreactors offer compact, flexible solutions ideal for remote or small-scale freshwater production.

small modular reactor vs microreactor Infographic

njnir.com

njnir.com