Active cooling in aerospace engineering utilizes mechanical systems like pumps and fans to efficiently remove heat from critical components, ensuring optimal performance under extreme conditions. Passive cooling relies on materials and design features such as heat sinks, radiative surfaces, and thermal coatings to dissipate heat without moving parts, reducing weight and increasing reliability. Choosing between active and passive cooling depends on mission requirements, including thermal load, system complexity, and energy availability.

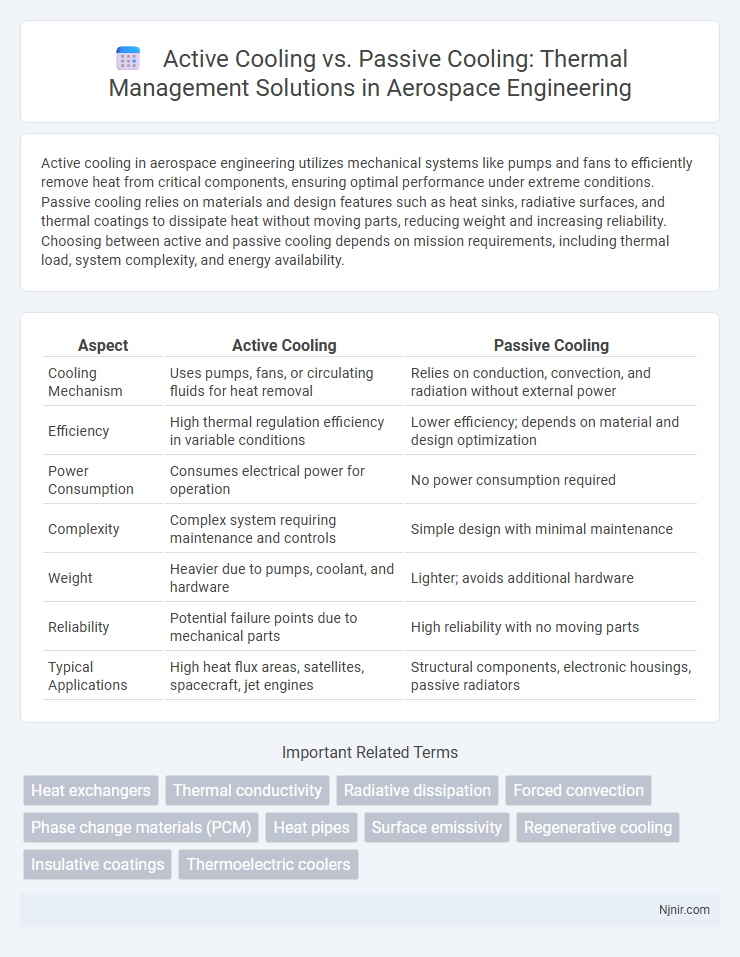

Table of Comparison

| Aspect | Active Cooling | Passive Cooling |

|---|---|---|

| Cooling Mechanism | Uses pumps, fans, or circulating fluids for heat removal | Relies on conduction, convection, and radiation without external power |

| Efficiency | High thermal regulation efficiency in variable conditions | Lower efficiency; depends on material and design optimization |

| Power Consumption | Consumes electrical power for operation | No power consumption required |

| Complexity | Complex system requiring maintenance and controls | Simple design with minimal maintenance |

| Weight | Heavier due to pumps, coolant, and hardware | Lighter; avoids additional hardware |

| Reliability | Potential failure points due to mechanical parts | High reliability with no moving parts |

| Typical Applications | High heat flux areas, satellites, spacecraft, jet engines | Structural components, electronic housings, passive radiators |

Introduction to Thermal Management in Aerospace Engineering

Thermal management in aerospace engineering involves controlling heat transfer to maintain optimal spacecraft and aircraft performance and avoid system failure. Active cooling uses mechanical components such as pumps, fans, and refrigeration cycles to remove excess heat, providing precise temperature regulation. Passive cooling relies on natural heat dissipation methods like radiation, conduction, and convection, offering simplicity and reliability without additional power consumption.

Fundamentals of Heat Transfer Mechanisms

Active cooling relies on external energy sources such as fans or pumps to enhance heat transfer via forced convection, improving temperature regulation in electronic devices. Passive cooling depends on natural convection, conduction, and radiation, utilizing heat sinks or finned surfaces to dissipate heat without moving parts or energy consumption. Understanding conduction through solids, convection from surfaces, and radiation emission is essential for designing efficient thermal management systems in various applications.

Overview of Active Cooling Systems

Active cooling systems utilize mechanical components such as fans, pumps, and refrigeration units to dissipate heat efficiently in thermal management applications. These systems actively transfer heat away from critical components, maintaining optimal operating temperatures and enhancing device performance. Common examples include liquid cooling loops and forced-air cooling, which provide precise temperature control compared to passive cooling methods.

Overview of Passive Cooling Techniques

Passive cooling techniques in thermal management rely on natural convection, conduction, and radiation to dissipate heat without the use of external energy sources. Common methods include heat sinks, thermal interface materials, phase change materials, and strategically designed ventilation pathways that enhance airflow and temperature regulation. These techniques are favored for their energy efficiency, reliability, and minimal maintenance requirements in applications ranging from electronics to building climate control.

Comparative Analysis: Efficiency of Active vs Passive Cooling

Active cooling systems, such as fans and liquid cooling, provide superior thermal management by actively dissipating heat and maintaining lower temperatures under high thermal loads. Passive cooling relies on heat sinks and natural convection, offering energy-efficient and maintenance-free operation but with limited capacity in high-performance or densely packed environments. Efficiency of active cooling surpasses passive solutions in scenarios demanding rapid heat removal, while passive cooling excels in silent, low-power applications with moderate heat generation.

Applications of Active Cooling in Aerospace Systems

Active cooling in aerospace systems plays a critical role in managing high thermal loads generated by engines, avionics, and electronic components to ensure reliable operation and safety. Applications include liquid-cooled heat exchangers, jet engine cooling channels, and cabin environmental control systems that maintain optimal temperatures under extreme flight conditions. The precise temperature regulation enabled by active cooling enhances aircraft performance, extends component lifespan, and supports advanced technologies such as high-power radar and propulsion systems.

Applications of Passive Cooling in Aerospace Systems

Passive cooling in aerospace systems is extensively applied in satellite thermal management, where radiators and heat pipes dissipate excess heat without mechanical components, ensuring reliability in space's harsh environment. This method is favored for its zero power consumption and minimal maintenance, critical for long-duration missions and unmanned spacecraft. Thermal coatings and phase change materials also play significant roles in stabilizing temperatures within aerospace electronics and instruments through passive means.

Design Considerations and Material Selection

Design considerations for active cooling emphasize integrating components like fans or liquid pumps to enhance heat dissipation, requiring careful evaluation of power consumption, noise levels, and system complexity. Passive cooling relies on materials with high thermal conductivity such as aluminum or copper and optimized fin geometry to maximize surface area for natural convection and radiation without mechanical parts. Selecting phase change materials or heat pipes can further improve passive solutions by storing or transferring heat efficiently while maintaining system reliability and minimizing maintenance.

Challenges and Limitations in Aerospace Cooling

Active cooling systems in aerospace face challenges such as high energy consumption, increased weight, and mechanical complexity, which can impact overall aircraft efficiency and reliability. Passive cooling relies on materials and design to dissipate heat without energy input but is limited by the thermal conductivity of materials and the aerodynamic constraints of aerospace structures. Both methods must contend with extreme environmental conditions, making thermal management a critical challenge for maintaining optimal performance and safety in aerospace applications.

Future Trends in Aerospace Thermal Management

Future trends in aerospace thermal management emphasize advanced active cooling systems utilizing phase change materials and microchannel heat exchangers for precise temperature control in extreme environments. Passive cooling techniques are evolving through the integration of multifunctional materials with enhanced radiative properties to reduce weight and improve energy efficiency. Hybrid thermal management solutions combining active and passive methods are gaining prominence to optimize system reliability and performance in next-generation aerospace designs.

Heat exchangers

Heat exchangers in active cooling systems use forced convection to efficiently transfer heat away from components, while passive cooling relies on natural convection and conduction without mechanical assistance.

Thermal conductivity

Active cooling enhances thermal conductivity through forced convection and heat transfer mechanisms, while passive cooling relies on material thermal conductivity and natural convection to dissipate heat effectively.

Radiative dissipation

Radiative dissipation enhances passive cooling by effectively emitting thermal radiation to manage heat without energy consumption, contrasting with energy-dependent active cooling systems.

Forced convection

Forced convection in active cooling systems enhances thermal management efficiency by using fans or pumps to increase heat transfer rates compared to passive cooling methods relying on natural convection and conduction.

Phase change materials (PCM)

Phase change materials (PCM) enhance passive cooling efficiency in thermal management by absorbing and releasing latent heat during phase transitions, offering energy-efficient temperature regulation compared to active cooling systems.

Heat pipes

Heat pipes in passive cooling systems efficiently transfer heat through phase change without external power, offering reliability and silent operation compared to energy-dependent active cooling methods.

Surface emissivity

Higher surface emissivity significantly enhances passive cooling efficiency by maximizing thermal radiation, whereas active cooling systems rely less on emissivity due to mechanical heat dissipation methods.

Regenerative cooling

Regenerative cooling enhances thermal management by actively circulating coolant through heat-intensive components to absorb and dissipate heat more effectively than passive cooling methods relying solely on natural convection and radiation.

Insulative coatings

Insulative coatings enhance passive cooling by reducing heat transfer through thermal barriers, offering energy-efficient temperature regulation compared to energy-consuming active cooling systems.

Thermoelectric coolers

Thermoelectric coolers provide active cooling by using the Peltier effect to transfer heat efficiently without moving parts, offering precise thermal management compared to passive cooling methods relying on natural convection and conduction.

active cooling vs passive cooling (thermal management) Infographic

njnir.com

njnir.com