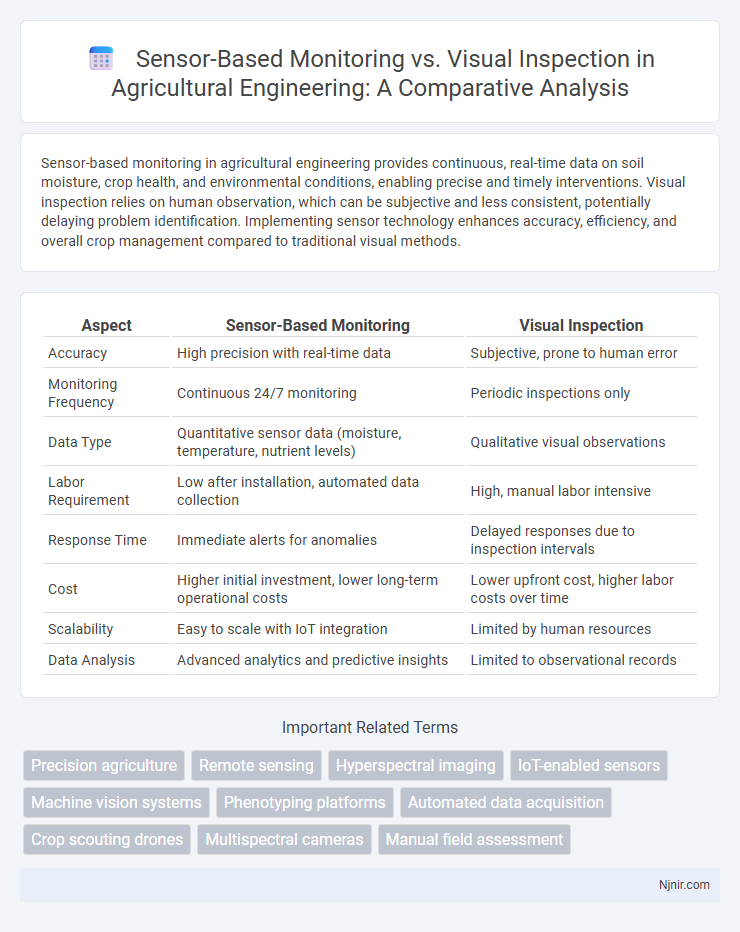

Sensor-based monitoring in agricultural engineering provides continuous, real-time data on soil moisture, crop health, and environmental conditions, enabling precise and timely interventions. Visual inspection relies on human observation, which can be subjective and less consistent, potentially delaying problem identification. Implementing sensor technology enhances accuracy, efficiency, and overall crop management compared to traditional visual methods.

Table of Comparison

| Aspect | Sensor-Based Monitoring | Visual Inspection |

|---|---|---|

| Accuracy | High precision with real-time data | Subjective, prone to human error |

| Monitoring Frequency | Continuous 24/7 monitoring | Periodic inspections only |

| Data Type | Quantitative sensor data (moisture, temperature, nutrient levels) | Qualitative visual observations |

| Labor Requirement | Low after installation, automated data collection | High, manual labor intensive |

| Response Time | Immediate alerts for anomalies | Delayed responses due to inspection intervals |

| Cost | Higher initial investment, lower long-term operational costs | Lower upfront cost, higher labor costs over time |

| Scalability | Easy to scale with IoT integration | Limited by human resources |

| Data Analysis | Advanced analytics and predictive insights | Limited to observational records |

Introduction to Crop Monitoring Techniques

Sensor-based monitoring utilizes advanced technologies like infrared and multispectral sensors to capture precise data on crop health, growth patterns, and environmental conditions, enabling real-time and continuous analysis. Visual inspection relies on human observation to detect visible signs of stress or disease but is limited by subjective interpretation and periodic assessment. Integrating sensor-based monitoring with traditional visual inspection enhances accuracy and efficiency in crop management, supporting timely decision-making for increased yield and sustainability.

Overview of Sensor-Based Monitoring Systems

Sensor-based monitoring systems utilize advanced technologies such as IoT sensors, machine learning algorithms, and real-time data analytics to continuously track equipment performance and environmental conditions. These systems provide precise, objective measurements of parameters like temperature, vibration, and pressure, enabling early detection of anomalies and predictive maintenance. Compared to visual inspection, sensor-based monitoring reduces human error, increases monitoring frequency, and enhances reliability through automated data collection and centralized reporting.

Visual Inspection Methods in Agriculture

Visual inspection methods in agriculture involve the manual examination of crops, plants, and soil by experts to identify diseases, pests, nutrient deficiencies, and growth anomalies. This approach leverages human expertise to interpret subtle visual cues such as discoloration, wilting, or deformation, offering a direct and intuitive assessment. While labor-intensive and subjective, visual inspection remains critical for early problem detection and decision-making in field management.

Accuracy: Sensors vs. Human Observation

Sensor-based monitoring delivers higher accuracy than visual inspection by consistently capturing real-time data with minimal human error, enabling precise detection of anomalies or changes. Advanced sensors can measure parameters such as temperature, pressure, and vibration at a granular level, surpassing the subjective limitations of human observation. Visual inspections rely heavily on the inspector's experience and conditions like lighting, leading to potential inconsistencies and missed defects.

Data Collection and Analysis Capabilities

Sensor-based monitoring offers continuous, real-time data collection with high precision and the ability to capture quantitative measurements such as temperature, vibration, and pressure, enabling advanced analytics and predictive maintenance. Visual inspection relies on periodic, manual observation that is subjective and often limited to surface-level anomalies detectable by the human eye. Data analysis from sensor inputs supports automated trend detection and anomaly identification, whereas visual inspection data requires manual recording and interpretation, resulting in lower consistency and delayed response times.

Labor and Resource Efficiency Comparison

Sensor-based monitoring significantly reduces labor requirements by enabling continuous, automated data collection and real-time analysis, minimizing the need for manual inspections. Visual inspection demands more human resources due to its dependence on skilled personnel to perform periodic evaluations, which can be time-consuming and prone to human error. Implementing sensor technology optimizes resource allocation, enhances efficiency, and lowers operational costs compared to traditional visual inspection methods.

Real-Time Monitoring and Response

Sensor-based monitoring enables real-time data collection and analysis, providing continuous, precise insights into system performance and environmental changes. Visual inspection relies on periodic human observations, often resulting in delayed detection and response to issues. Real-time monitoring through sensors facilitates immediate alerts and automated corrective actions, enhancing operational efficiency and reducing downtime.

Cost Implications of Sensor and Visual Approaches

Sensor-based monitoring systems often require higher initial capital investment due to the cost of advanced hardware and installation, but they provide continuous data collection that can reduce long-term maintenance expenses by enabling predictive maintenance. Visual inspection typically incurs lower upfront costs but demands frequent manual labor, leading to higher operational expenses and potential downtime due to missed defects or human error. Over time, sensor-based approaches tend to offer better cost-efficiency through improved asset lifespan and reduced unscheduled repairs compared to traditional visual inspection methods.

Scalability in Large-Scale Farming Operations

Sensor-based monitoring offers unparalleled scalability in large-scale farming by enabling continuous, real-time data collection across vast acres without the need for proportional increases in labor. Visual inspection, limited by human resources and time, often becomes impractical and less accurate as farm size expands. Integrating IoT sensors with advanced analytics ensures efficient resource management, early threat detection, and optimized crop yields at scale.

Future Trends: Integrating Sensors and Visual Inspection

Future trends in maintenance emphasize the integration of sensor-based monitoring with visual inspection to enhance accuracy and efficiency. Combining real-time data from IoT sensors with high-resolution imaging technology enables predictive analytics, reducing downtime and improving asset reliability. Advanced AI algorithms process multi-source inputs, facilitating early fault detection and comprehensive condition assessment in industrial applications.

Precision agriculture

Sensor-based monitoring in precision agriculture offers real-time, accurate data on soil moisture, nutrient levels, and crop health, significantly improving decision-making compared to traditional visual inspection methods.

Remote sensing

Remote sensing in sensor-based monitoring provides continuous, real-time data acquisition for accurate, large-scale environmental analysis, surpassing the spatial limitations and subjectivity inherent in traditional visual inspection methods.

Hyperspectral imaging

Hyperspectral imaging provides precise sensor-based monitoring by capturing detailed spectral data for early anomaly detection, outperforming traditional visual inspection in accuracy and efficiency.

IoT-enabled sensors

IoT-enabled sensor-based monitoring provides continuous, real-time data collection and predictive insights that significantly enhance accuracy and efficiency compared to intermittent, subjective visual inspections.

Machine vision systems

Machine vision systems offer sensor-based monitoring that ensures higher accuracy, real-time data analysis, and automated defect detection compared to traditional visual inspection methods.

Phenotyping platforms

Sensor-based monitoring in phenotyping platforms offers continuous, high-throughput data collection with precise quantification compared to the subjective and labor-intensive nature of visual inspection.

Automated data acquisition

Sensor-based monitoring enables automated data acquisition with continuous, real-time accuracy, surpassing the intermittent and subjective nature of traditional visual inspection.

Crop scouting drones

Crop scouting drones equipped with sensor-based monitoring provide precise, real-time data on plant health, enabling early pest and disease detection compared to traditional visual inspection methods.

Multispectral cameras

Multispectral cameras enable more precise sensor-based monitoring by capturing diverse wavelength data beyond human visual range, significantly enhancing early detection accuracy compared to traditional visual inspection.

Manual field assessment

Manual field assessment relies heavily on expert visual inspection, which can be subjective and time-consuming compared to continuous, objective sensor-based monitoring systems.

sensor-based monitoring vs visual inspection Infographic

njnir.com

njnir.com