Algal biofuel offers higher lipid content and faster growth rates compared to cellulosic biofuel, making it a more efficient source for sustainable energy production. Cellulosic biofuel, derived from plant biomass such as agricultural residues, provides a renewable alternative with lower competition for food resources. Both biofuels present promising solutions for reducing greenhouse gas emissions and advancing renewable energy technologies in biological engineering.

Table of Comparison

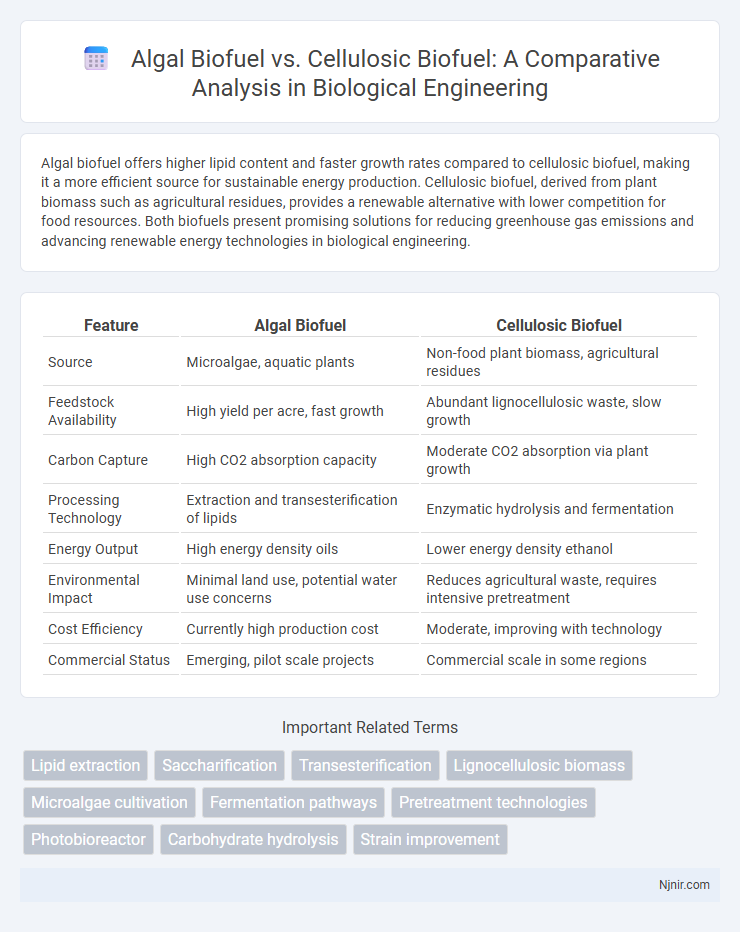

| Feature | Algal Biofuel | Cellulosic Biofuel |

|---|---|---|

| Source | Microalgae, aquatic plants | Non-food plant biomass, agricultural residues |

| Feedstock Availability | High yield per acre, fast growth | Abundant lignocellulosic waste, slow growth |

| Carbon Capture | High CO2 absorption capacity | Moderate CO2 absorption via plant growth |

| Processing Technology | Extraction and transesterification of lipids | Enzymatic hydrolysis and fermentation |

| Energy Output | High energy density oils | Lower energy density ethanol |

| Environmental Impact | Minimal land use, potential water use concerns | Reduces agricultural waste, requires intensive pretreatment |

| Cost Efficiency | Currently high production cost | Moderate, improving with technology |

| Commercial Status | Emerging, pilot scale projects | Commercial scale in some regions |

Introduction to Algal and Cellulosic Biofuels

Algal biofuels are derived from microalgae, which have high lipid content suitable for conversion into biodiesel, offering rapid growth rates and the ability to thrive in diverse environments. Cellulosic biofuels are produced from lignocellulosic biomass, such as agricultural residues, grasses, and wood, utilizing cellulose and hemicellulose components to generate ethanol or other biofuels through enzymatic hydrolysis and fermentation. Both biofuels present sustainable alternatives to fossil fuels by leveraging renewable biological materials with significant potential for reducing greenhouse gas emissions.

Feedstock Sources and Availability

Algal biofuel is derived from algae, which can be cultivated in diverse environments including freshwater, marine waters, and wastewater, offering high yield per acre without competing for arable land. Cellulosic biofuel, on the other hand, relies on lignocellulosic biomass such as agricultural residues, grasses, and wood chips, which are abundant but subject to seasonal availability and require extensive processing to break down cellulose. The scalability of algal biofuel depends on controlled growth conditions and nutrient supply, whereas cellulosic biofuel leverages waste materials, making it more accessible in regions with established agricultural industries.

Biomass Conversion Technologies

Algal biofuel production relies on lipid extraction and transesterification processes to convert microalgae biomass into biodiesel, leveraging high oil yields and rapid growth rates. Cellulosic biofuel utilizes enzymatic hydrolysis and fermentation technologies to break down lignocellulosic biomass into fermentable sugars, which are then converted into ethanol or other biofuels. Advanced thermochemical methods, such as pyrolysis and gasification, are also explored to enhance conversion efficiency and expand feedstock versatility in both biofuel types.

Energy Yield and Efficiency Comparisons

Algal biofuel demonstrates significantly higher energy yield per acre compared to cellulosic biofuel, producing up to 5,000 gallons per acre annually versus 200-400 gallons for cellulosic sources like switchgrass or miscanthus. The lipid content in algae allows for more efficient conversion to biodiesel, with energy efficiencies reaching approximately 3-5 times greater than cellulose-based biofuels, which rely on complex enzymatic hydrolysis and fermentation processes. While cellulosic biofuels benefit from abundant feedstock availability, algal biofuels offer superior carbon fixation rates and faster biomass production cycles, contributing to enhanced overall energy efficiency.

Environmental Impact and Sustainability

Algal biofuel offers significant environmental benefits by utilizing non-arable land and requiring less freshwater, resulting in lower greenhouse gas emissions and reduced competition with food crops. Cellulosic biofuel, derived from agricultural residues and dedicated energy crops, promotes waste utilization and enhances carbon sequestration but may involve higher land and water use compared to algal sources. Both biofuels contribute to sustainability through renewable energy production, yet algal biofuels demonstrate superior potential in minimizing environmental footprint and conserving natural resources.

Land and Water Resource Requirements

Algal biofuel production requires significantly less arable land compared to cellulosic biofuel, as algae can be cultivated on non-arable land and in controlled aquatic environments. Water usage for algal biofuels, while high due to cultivation in bioreactors or ponds, can utilize saline or wastewater, reducing competition for freshwater resources essential in cellulosic biofuel production from terrestrial crops. This makes algal biofuels more sustainable in terms of land and freshwater conservation, particularly in regions facing agricultural land scarcity and water stress.

Economic Viability and Scalability

Algal biofuel offers high productivity rates with potential yields up to 10 times greater than cellulosic biofuel from terrestrial biomass, but currently faces high capital and operational costs limiting economic viability. Cellulosic biofuel benefits from established agricultural feedstock supply chains and lower production expenses, enhancing near-term scalability despite lower energy density and slower growth rates. Advances in genetically engineered algae strains and biorefinery integration could reduce costs and improve scalability, yet cellulosic pathways remain more commercially mature with pilot-scale refineries demonstrating economic potential.

Carbon Footprint and Greenhouse Gas Emissions

Algal biofuel exhibits a significantly lower carbon footprint compared to cellulosic biofuel due to higher photosynthetic efficiency and rapid biomass production, enabling greater carbon sequestration. Life cycle assessments indicate algal biofuels can reduce greenhouse gas emissions by up to 60-80%, whereas cellulosic biofuels typically achieve a 40-60% reduction relative to fossil fuels. The cultivation of algae in controlled environments minimizes land use change emissions, a common issue in cellulosic biofuel feedstock production such as miscanthus or switchgrass.

Challenges in Commercialization

Algal biofuel faces commercialization challenges due to high cultivation costs, energy-intensive harvesting processes, and the need for large-scale photobioreactor infrastructure. Cellulosic biofuel commercialization struggles with efficient pretreatment methods, low enzyme activity for biomass conversion, and supply chain complexities in sourcing diverse feedstocks. Both biofuels require advancements in technology to reduce production costs and improve scalability for competitive market viability.

Future Prospects in Biofuel Development

Algal biofuel offers significant future prospects due to its high yield per acre, ability to grow on non-arable land, and strong potential for carbon dioxide sequestration, making it a sustainable alternative to fossil fuels. Cellulosic biofuel, derived from agricultural residues and non-food biomass, promises scalability and cost-effectiveness in biofuel production, leveraging advancements in enzyme technology and fermentation processes. Both biofuels are critical in diversifying energy sources and reducing greenhouse gas emissions, with ongoing research focusing on improving conversion efficiency and economic viability.

Lipid extraction

Algal biofuel production achieves higher lipid extraction efficiency compared to cellulosic biofuel, leveraging microalgae's rapid lipid accumulation for superior biodiesel yield.

Saccharification

Saccharification efficiency in algal biofuel production is generally higher than in cellulosic biofuel due to the simpler carbohydrate structure of algae, enabling faster enzymatic conversion into fermentable sugars.

Transesterification

Transesterification efficiently converts algal biofuel into biodiesel with higher lipid content compared to cellulosic biofuel, which requires additional pretreatment steps to access fermentable sugars.

Lignocellulosic biomass

Lignocellulosic biomass in cellulosic biofuel offers sustainable, abundant feedstock with higher carbon efficiency compared to algae-based biofuels, which rely on aquatic photosynthetic organisms but face challenges in scalability and harvesting.

Microalgae cultivation

Microalgae cultivation for algal biofuel offers higher lipid productivity and faster growth rates compared to cellulosic biofuel derived from lignocellulosic biomass, making it a more efficient and sustainable feedstock for renewable energy production.

Fermentation pathways

Algal biofuel primarily utilizes lipid extraction and transesterification while cellulosic biofuel relies on fermentation pathways such as enzymatic hydrolysis followed by microbial conversion of cellulose-derived sugars into ethanol.

Pretreatment technologies

Algal biofuel pretreatment primarily involves hydrothermal liquefaction and enzymatic hydrolysis to efficiently break down lipids and carbohydrates, whereas cellulosic biofuel relies on advanced mechanical, chemical, and enzymatic pretreatments like steam explosion, acid hydrolysis, and cellulase enzymes to deconstruct lignocellulosic biomass.

Photobioreactor

Photobioreactors enhance algal biofuel production by optimizing light exposure and nutrient delivery, offering higher yields and faster growth rates compared to cellulosic biofuel processes reliant on lignocellulosic biomass conversion.

Carbohydrate hydrolysis

Algal biofuel utilizes enzymatic carbohydrate hydrolysis to efficiently break down complex polysaccharides into fermentable sugars, while cellulosic biofuel relies on pretreatment techniques to overcome lignin barriers for effective hydrolysis of cellulose and hemicellulose into bioavailable sugars.

Strain improvement

Strain improvement in algal biofuel focuses on enhancing lipid productivity and stress tolerance through genetic engineering, while cellulosic biofuel strain improvement prioritizes increasing cellulose-degrading enzyme efficiency and biomass yield.

Algal biofuel vs Cellulosic biofuel Infographic

njnir.com

njnir.com