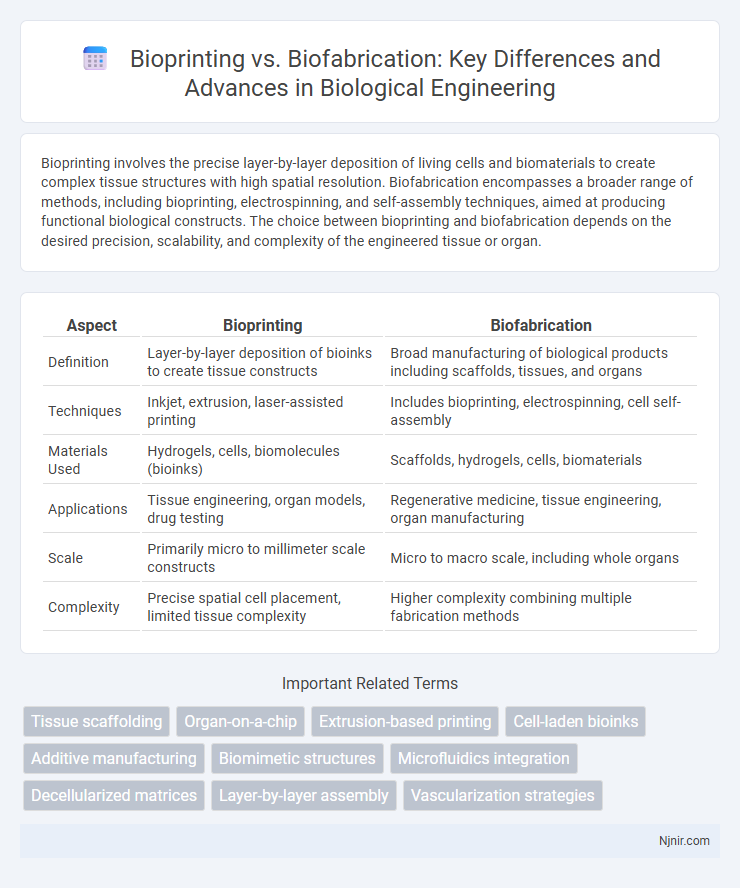

Bioprinting involves the precise layer-by-layer deposition of living cells and biomaterials to create complex tissue structures with high spatial resolution. Biofabrication encompasses a broader range of methods, including bioprinting, electrospinning, and self-assembly techniques, aimed at producing functional biological constructs. The choice between bioprinting and biofabrication depends on the desired precision, scalability, and complexity of the engineered tissue or organ.

Table of Comparison

| Aspect | Bioprinting | Biofabrication |

|---|---|---|

| Definition | Layer-by-layer deposition of bioinks to create tissue constructs | Broad manufacturing of biological products including scaffolds, tissues, and organs |

| Techniques | Inkjet, extrusion, laser-assisted printing | Includes bioprinting, electrospinning, cell self-assembly |

| Materials Used | Hydrogels, cells, biomolecules (bioinks) | Scaffolds, hydrogels, cells, biomaterials |

| Applications | Tissue engineering, organ models, drug testing | Regenerative medicine, tissue engineering, organ manufacturing |

| Scale | Primarily micro to millimeter scale constructs | Micro to macro scale, including whole organs |

| Complexity | Precise spatial cell placement, limited tissue complexity | Higher complexity combining multiple fabrication methods |

Introduction to Bioprinting and Biofabrication

Bioprinting is an advanced additive manufacturing process that creates three-dimensional biological structures by precisely depositing bioinks containing living cells and biomaterials, enabling the fabrication of complex tissues and organs. Biofabrication encompasses a broader field, integrating multiple techniques including bioprinting, cell self-assembly, and scaffold-based methods to engineer functional biological constructs. Both approaches aim to revolutionize regenerative medicine by addressing the challenges of tissue engineering, with bioprinting offering high-resolution spatial control and biofabrication providing versatile strategies for tissue complexity.

Defining Bioprinting: Concepts and Techniques

Bioprinting is a precise additive manufacturing process that creates three-dimensional living tissues by depositing bioinks containing cells and biomaterials layer-by-layer. Techniques such as inkjet, extrusion, and laser-assisted bioprinting enable the fabrication of complex tissue structures with high spatial resolution and cell viability. This approach contrasts with broader biofabrication, which encompasses a range of methods including scaffold-based assembly and cell self-organization to engineer biological constructs.

What Is Biofabrication? Scope and Methods

Biofabrication encompasses advanced techniques for creating biological products by assembling living cells, biomaterials, and bioactive molecules into functional tissues or organs using methods such as 3D bioprinting, robotic-assisted cell patterning, and scaffold-based fabrication. Its scope extends across regenerative medicine, tissue engineering, and drug development, aiming to replicate native tissue architecture and function. Cutting-edge biofabrication leverages additive manufacturing technologies, microfluidics, and biomaterial science to achieve precise spatial control of cellular microenvironments and complex tissue constructs.

Key Differences Between Bioprinting and Biofabrication

Bioprinting is a subset of biofabrication that specifically involves the layer-by-layer deposition of living cells and biomaterials to create tissue-like structures with precise spatial control. Biofabrication encompasses a broader range of techniques, including bioprinting, electrospinning, and self-assembly, aimed at producing complex biological constructs for regenerative medicine and tissue engineering. The key difference lies in bioprinting's focus on additive manufacturing technology using bioinks, while biofabrication integrates multiple fabrication methods to build functional biological tissues.

Materials Used: Bioinks vs Biomaterials

Bioinks in bioprinting are specialized formulations containing living cells suspended within hydrogels, designed to maintain cell viability and promote tissue formation during the layer-by-layer printing process. In contrast, biofabrication uses a broader range of biomaterials, including synthetic polymers, ceramics, and composite scaffolds, to build complex tissue architectures through various assembly techniques beyond printing, such as self-assembly and directed organization. The choice between bioinks and biomaterials depends on the desired tissue complexity, mechanical properties, and biological functionality required for applications in regenerative medicine and tissue engineering.

Technological Advances in Both Fields

Bioprinting leverages precise layer-by-layer deposition of biomaterials and living cells to create complex tissue structures with high spatial resolution, using techniques such as inkjet, extrusion, and laser-assisted printing. Biofabrication encompasses a broader range of automated processes, including scaffold-free methods and microfluidic devices, aimed at fabricating functional biological constructs that mimic native tissue architecture. Recent technological advances in both fields highlight improved biomaterial formulations, enhanced cell viability, and integration of real-time monitoring systems to accelerate tissue engineering and regenerative medicine applications.

Applications in Regenerative Medicine

Bioprinting enables precise placement of living cells and biomaterials to create complex tissue structures, making it ideal for customized tissue engineering in regenerative medicine. Biofabrication encompasses a broader range of techniques, including bioprinting, that fabricate biological products such as scaffolds, organoids, and implantable tissues for tissue repair and replacement. Both methods significantly advance regenerative therapies by facilitating the development of functional tissues that promote healing and restore damaged organs.

Current Challenges and Limitations

Bioprinting faces significant challenges including limited resolution, scaffold material biocompatibility, and maintaining cell viability during the printing process. Biofabrication struggles with replicating complex tissue structures and vascularization critical for functional tissue integration. Both fields confront scalability issues and regulatory hurdles that impede clinical translation and widespread application.

Future Trends in Bioprinting and Biofabrication

Future trends in bioprinting and biofabrication include enhanced precision through advanced biomaterials and improved multi-cellular printing techniques that enable the creation of complex tissue structures. Integration of artificial intelligence and machine learning optimizes biofabrication processes, leading to personalized regenerative therapies and scalable production of organoids. Emerging innovations focus on vascularization and dynamic bioinks, crucial for functional tissue viability and long-term transplantation success.

Conclusion: Choosing the Right Approach

Selecting between bioprinting and biofabrication depends on the desired complexity, precision, and scalability of tissue engineering projects. Bioprinting excels in layer-by-layer deposition for intricate cellular architectures, while biofabrication offers versatile methods, including scaffold-based and scaffold-free techniques, for generating functional tissues. Optimizing the choice requires evaluating factors like biomaterial compatibility, cell viability, and application-specific requirements to achieve successful regenerative outcomes.

Tissue scaffolding

Bioprinting precisely deposits living cells and biomaterials layer-by-layer to create complex tissue scaffolds, while biofabrication encompasses broader techniques including self-assembly and electrospinning to engineer functional tissue scaffolds for regenerative medicine.

Organ-on-a-chip

Organ-on-a-chip technology integrates bioprinting and biofabrication techniques to create precisely structured microfluidic devices that mimic organ-level functions for advanced drug testing and disease modeling.

Extrusion-based printing

Extrusion-based bioprinting, a subset of biofabrication, uses precise deposition of bioinks to create complex tissue structures with high cell viability and spatial resolution.

Cell-laden bioinks

Cell-laden bioinks in bioprinting offer precise spatial control for tissue engineering, whereas biofabrication encompasses broader scaffold-based assembly techniques integrating bioinks for complex tissue structures.

Additive manufacturing

Additive manufacturing in bioprinting precisely deposits bioinks layer-by-layer to create complex tissue structures, while biofabrication encompasses a broader range of techniques including scaffold-based and scaffold-free methods for constructing biological constructs.

Biomimetic structures

Bioprinting precisely deposits living cells layer-by-layer to create complex biomimetic structures, while biofabrication encompasses diverse techniques integrating cells, biomaterials, and bioactive molecules for constructing functional tissue-like architectures.

Microfluidics integration

Microfluidics integration enhances bioprinting by enabling precise cell placement and controlled bioink flow, while in biofabrication it improves complex tissue structuring through dynamic microenvironment modulation.

Decellularized matrices

Decellularized matrices in bioprinting provide structurally precise scaffolds derived from native tissues, whereas biofabrication utilizes these matrices to create complex, functional tissue constructs by integrating cells and biomaterials.

Layer-by-layer assembly

Layer-by-layer assembly in bioprinting precisely deposits cells and biomaterials through controlled extrusion or inkjet techniques, whereas biofabrication encompasses broader methods including scaffold-free and modular assembly approaches for constructing complex tissue structures.

Vascularization strategies

Bioprinting employs precise layer-by-layer deposition of bioinks to create complex vascular networks, while biofabrication integrates multiple techniques like self-assembly and scaffold-based methods to enhance vascularization strategies for tissue engineering.

Bioprinting vs Biofabrication Infographic

njnir.com

njnir.com