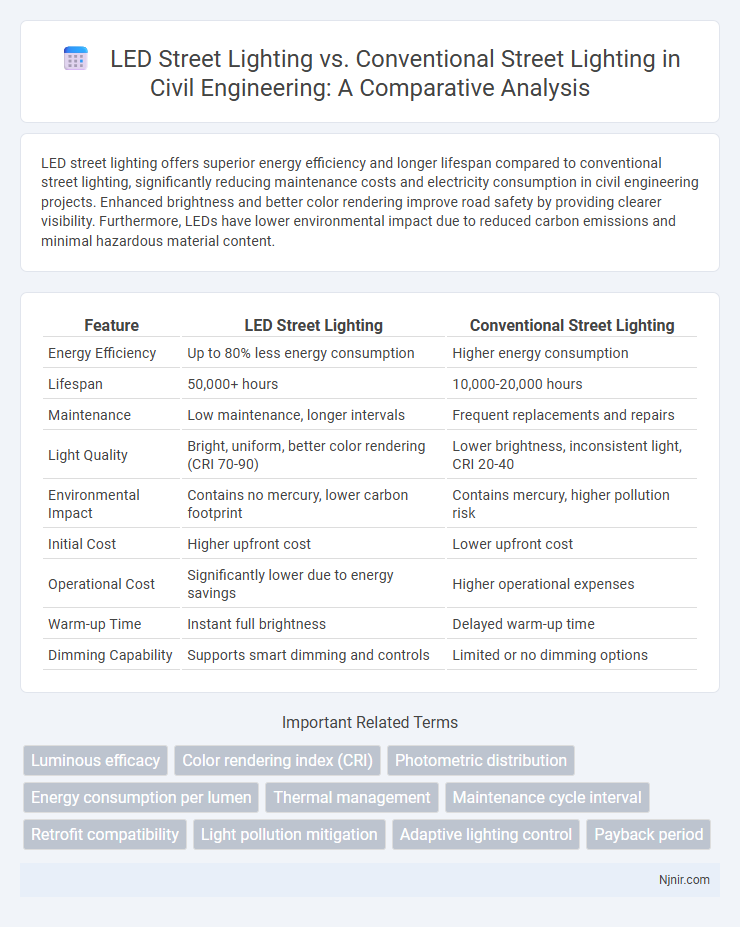

LED street lighting offers superior energy efficiency and longer lifespan compared to conventional street lighting, significantly reducing maintenance costs and electricity consumption in civil engineering projects. Enhanced brightness and better color rendering improve road safety by providing clearer visibility. Furthermore, LEDs have lower environmental impact due to reduced carbon emissions and minimal hazardous material content.

Table of Comparison

| Feature | LED Street Lighting | Conventional Street Lighting |

|---|---|---|

| Energy Efficiency | Up to 80% less energy consumption | Higher energy consumption |

| Lifespan | 50,000+ hours | 10,000-20,000 hours |

| Maintenance | Low maintenance, longer intervals | Frequent replacements and repairs |

| Light Quality | Bright, uniform, better color rendering (CRI 70-90) | Lower brightness, inconsistent light, CRI 20-40 |

| Environmental Impact | Contains no mercury, lower carbon footprint | Contains mercury, higher pollution risk |

| Initial Cost | Higher upfront cost | Lower upfront cost |

| Operational Cost | Significantly lower due to energy savings | Higher operational expenses |

| Warm-up Time | Instant full brightness | Delayed warm-up time |

| Dimming Capability | Supports smart dimming and controls | Limited or no dimming options |

Introduction to Street Lighting Technologies

LED street lighting offers enhanced energy efficiency and longer lifespan compared to conventional street lighting technologies such as high-pressure sodium and metal halide lamps. These advanced LEDs provide superior luminance, better color rendering, and reduced maintenance costs, making them ideal for modern urban infrastructure. Conventional street lighting often consumes more power and has a shorter operational life, leading to higher overall expenses and environmental impact.

Overview of LED Street Lighting Systems

LED street lighting systems utilize light-emitting diodes to provide energy-efficient illumination with longer lifespan and reduced maintenance compared to conventional high-pressure sodium or mercury vapor lamps. These systems offer superior color rendering, instant startup, and precise light direction, significantly reducing light pollution and operational costs. Integration with smart controls enables adaptive lighting that enhances urban safety and sustainability.

Conventional Street Lighting: Types and Features

Conventional street lighting primarily includes high-pressure sodium (HPS), mercury vapor, and metal halide lamps, each characterized by specific light quality and energy efficiency levels. HPS lamps produce a warm, amber glow with high luminous efficacy but limited color rendering, while mercury vapor lamps emit a bluish-white light with lower efficiency and shorter lifespan. Metal halide lamps offer better color rendering and brighter illumination but consume more energy and have a shorter operational life compared to modern LED systems.

Energy Efficiency Comparison: LED vs Conventional

LED street lighting consumes up to 50-70% less energy than conventional street lighting technologies, such as high-pressure sodium (HPS) and metal halide lamps. The superior luminous efficacy of LEDs, measured in lumens per watt, ranges from 80 to 150 lm/W, compared to 35-90 lm/W for conventional options, resulting in significant energy savings. Reduced energy consumption of LED lighting also leads to lower greenhouse gas emissions, supporting sustainable urban infrastructure goals.

Lifespan and Durability of Street Lighting Solutions

LED street lighting offers significantly longer lifespan, typically exceeding 50,000 hours, compared to conventional street lighting solutions that usually range between 10,000 to 20,000 hours. The durability of LED fixtures is enhanced by solid-state components, making them more resistant to shocks, vibrations, and harsh weather conditions than traditional metal halide or high-pressure sodium lamps. This extended lifespan and robust design reduce maintenance costs and replacement frequency, improving overall cost-efficiency for urban lighting infrastructure.

Maintenance Requirements and Costs

LED street lighting significantly reduces maintenance requirements and costs compared to conventional street lighting due to its longer lifespan, often exceeding 50,000 hours, which minimizes replacement frequency. Conventional streetlights, such as high-pressure sodium or metal halide lamps, typically require bulb replacements every 10,000 to 24,000 hours and frequent ballast maintenance, increasing labor and material expenses. Lower energy consumption of LEDs also contributes to overall cost savings by reducing electricity bills and infrastructure strain over time.

Environmental Impact Assessment

LED street lighting significantly reduces energy consumption by up to 50-70% compared to conventional high-pressure sodium or metal halide lamps, leading to lower greenhouse gas emissions and decreased carbon footprint. The longer lifespan of LED fixtures results in less frequent replacements and reduced waste generation, minimizing environmental strain associated with manufacturing and disposal. Moreover, LED technology limits light pollution and reduces harmful blue light emissions, promoting better ecosystem health and biodiversity preservation in urban and suburban areas.

Light Quality and Visibility Performance

LED street lighting provides superior light quality with higher color rendering index (CRI) values, enhancing visibility by producing clear, uniform, and glare-reduced illumination compared to conventional street lighting such as high-pressure sodium or metal halide lamps. The improved spectral distribution of LED technology supports better object recognition and safety on roads, leading to increased pedestrian and driver visibility during nighttime conditions. Conventional street lighting often suffers from lower CRI and uneven light patterns, resulting in reduced visual acuity and increased dark spots that compromise overall visibility performance.

Implementation Challenges and Considerations

Implementing LED street lighting involves challenges such as high upfront costs and compatibility with existing infrastructure, requiring careful financial planning and technical assessments. Considerations include ensuring proper light distribution to avoid glare and light pollution, as well as integrating smart controls for energy efficiency and maintenance monitoring. Conventional street lighting, often reliant on sodium vapor or metal halide lamps, faces issues like higher energy consumption and shorter lifespan, but benefits from established installation protocols and lower initial investment.

Future Trends in Street Lighting Technology

LED street lighting is rapidly overtaking conventional streetlighting due to its superior energy efficiency and longer lifespan, contributing to significant reductions in urban energy consumption. Future trends focus on smart street lighting systems that integrate IoT sensors and adaptive controls to optimize illumination based on real-time environmental data, enhancing safety and reducing operational costs. Emerging technologies also include solar-powered LEDs and advanced materials for improved durability, aligning with global sustainability goals.

Luminous efficacy

LED street lighting offers significantly higher luminous efficacy, often exceeding 100 lumens per watt, compared to conventional street lighting technologies like high-pressure sodium lamps, which typically provide around 50-70 lumens per watt.

Color rendering index (CRI)

LED street lighting typically offers a higher Color Rendering Index (CRI) of 70-90 compared to conventional street lighting's CRI of 20-50, resulting in better color accuracy and enhanced visibility for improved nighttime safety.

Photometric distribution

LED street lighting provides more precise photometric distribution with uniform luminance and reduced light pollution compared to conventional street lighting, enhancing visibility and energy efficiency.

Energy consumption per lumen

LED street lighting consumes up to 60% less energy per lumen compared to conventional street lighting, significantly enhancing energy efficiency and reducing operational costs.

Thermal management

LED street lighting features advanced thermal management systems that efficiently dissipate heat, extending lifespan and reducing maintenance costs compared to conventional street lighting.

Maintenance cycle interval

LED street lighting typically requires maintenance every 50,000 to 100,000 hours, significantly extending the maintenance cycle interval compared to conventional street lighting which often requires servicing every 10,000 to 20,000 hours.

Retrofit compatibility

LED street lighting offers superior retrofit compatibility with existing conventional street lighting fixtures, enabling cost-effective upgrades and enhanced energy efficiency without extensive infrastructure changes.

Light pollution mitigation

LED street lighting reduces light pollution by directing light precisely where needed, minimizing skyglow and glare compared to conventional street lighting.

Adaptive lighting control

Adaptive lighting control in LED street lighting reduces energy consumption by dynamically adjusting brightness based on real-time conditions, unlike conventional street lighting which operates at fixed illumination levels.

Payback period

LED street lighting offers a significantly shorter payback period, often between 2 to 4 years, compared to conventional street lighting due to lower energy consumption and maintenance costs.

LED street lighting vs Conventional street lighting Infographic

njnir.com

njnir.com