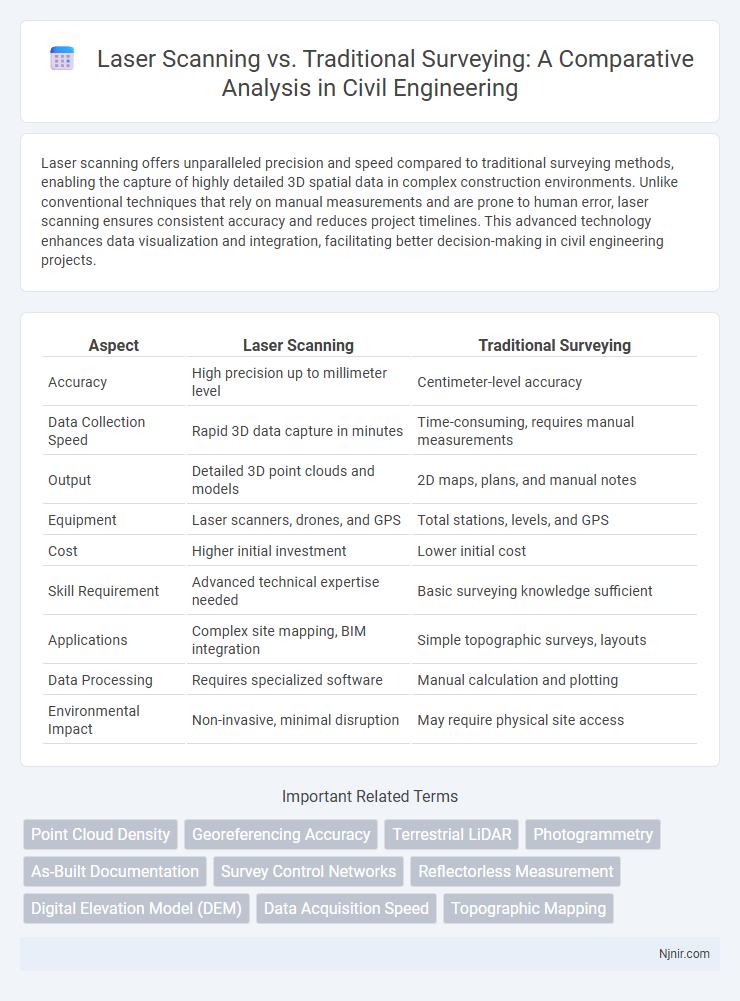

Laser scanning offers unparalleled precision and speed compared to traditional surveying methods, enabling the capture of highly detailed 3D spatial data in complex construction environments. Unlike conventional techniques that rely on manual measurements and are prone to human error, laser scanning ensures consistent accuracy and reduces project timelines. This advanced technology enhances data visualization and integration, facilitating better decision-making in civil engineering projects.

Table of Comparison

| Aspect | Laser Scanning | Traditional Surveying |

|---|---|---|

| Accuracy | High precision up to millimeter level | Centimeter-level accuracy |

| Data Collection Speed | Rapid 3D data capture in minutes | Time-consuming, requires manual measurements |

| Output | Detailed 3D point clouds and models | 2D maps, plans, and manual notes |

| Equipment | Laser scanners, drones, and GPS | Total stations, levels, and GPS |

| Cost | Higher initial investment | Lower initial cost |

| Skill Requirement | Advanced technical expertise needed | Basic surveying knowledge sufficient |

| Applications | Complex site mapping, BIM integration | Simple topographic surveys, layouts |

| Data Processing | Requires specialized software | Manual calculation and plotting |

| Environmental Impact | Non-invasive, minimal disruption | May require physical site access |

Introduction to Surveying Methods in Civil Engineering

Laser scanning in civil engineering delivers precise 3D point cloud data rapidly, enhancing accuracy and efficiency compared to traditional surveying. Traditional methods, such as total station and GPS surveying, rely on manual data collection and often require longer field time and post-processing. Integration of laser scanning streamlines topographic mapping and structural analysis, driving improved project outcomes and cost savings.

Fundamentals of Traditional Surveying Techniques

Traditional surveying techniques rely on established methods such as chain surveying, compass surveying, and leveling to measure land and map features. These methods emphasize manual data collection using tools like theodolites, prisms, and total stations, ensuring precise angular and distance measurements. Despite advancements, traditional surveying fundamentals remain crucial for understanding spatial relationships and providing a baseline for integrating modern technologies like laser scanning.

Overview of Laser Scanning Technology

Laser scanning technology employs LiDAR sensors to capture high-density, three-dimensional point clouds that accurately represent surfaces and structures, enhancing precision over traditional surveying methods. This technology enables rapid data acquisition across large areas, significantly reducing field time while increasing data detail and spatial resolution. Laser scanning also facilitates advanced digital modeling, supporting applications in construction, geology, and infrastructure monitoring.

Accuracy and Precision: Laser Scanning vs. Traditional Surveying

Laser scanning delivers superior accuracy and precision by capturing millions of data points in high resolution, enabling detailed 3D models and measurements with minimal human error. Traditional surveying methods, relying on manual measurements and instruments like total stations or GPS, often result in lower data density and potential for human-induced inaccuracies. Consequently, laser scanning enhances precision in complex environments and large-scale projects where exact spatial data is critical.

Data Collection Speed and Efficiency Comparison

Laser scanning captures millions of data points within seconds, significantly outperforming traditional surveying methods that rely on manual measurements and incremental data gathering. The high-speed data acquisition of laser scanning reduces field time by up to 70%, enhancing project efficiency and enabling rapid 3D model generation. Traditional surveying often requires multiple site visits and complex setups, whereas laser scanning provides comprehensive, accurate spatial data in a single session.

Cost Implications: Initial Investment and Long-term Benefits

Laser scanning requires a higher initial investment due to advanced equipment costs, typically ranging from $30,000 to $100,000, compared to traditional surveying tools that may cost under $10,000. Long-term benefits of laser scanning include increased data accuracy, faster project completion, and reduced labor expenses, which can significantly lower overall operational costs over time. Traditional surveying, while less expensive upfront, often incurs higher ongoing costs due to longer survey durations and potential for human error requiring rework.

Safety and Accessibility in Challenging Environments

Laser scanning significantly enhances safety by minimizing the need for surveyors to physically access hazardous or difficult-to-reach locations, reducing exposure to falls, unstable terrain, or toxic materials. Traditional surveying methods often require direct human presence on-site, increasing risk in challenging environments such as steep slopes, confined spaces, or contaminated zones. The remote data capture capabilities of laser scanning improve accessibility and data accuracy while ensuring personnel remain in secure areas.

Applications in Civil Engineering Projects

Laser scanning offers rapid, high-precision 3D data capture for detailed topographic mapping, structural analysis, and monitoring in civil engineering projects. Traditional surveying remains essential for boundary surveys, construction staking, and legal documentation due to its accuracy in horizontal and vertical control points. Integrating laser scanning with conventional methods enhances project efficiency, improves data accuracy, and facilitates better decision-making in infrastructure design, construction management, and quality control.

Integration with BIM and Digital Workflows

Laser scanning offers highly accurate 3D point cloud data that seamlessly integrates with BIM software, enhancing precision in digital workflows and enabling real-time model updates. Traditional surveying provides reliable geometric data but often requires conversion and manual input to fit BIM environments, which can slow down project timelines. Combining laser scanning with BIM accelerates project coordination, clash detection, and facility management by delivering richer datasets directly compatible with digital construction processes.

Future Trends and Technological Advancements

Laser scanning advances are revolutionizing future surveying by enabling faster data capture with higher accuracy and detailed 3D modeling, surpassing traditional methods reliant on manual measurements and optical instruments. Emerging technologies such as AI-driven data processing, drone-mounted LiDAR, and real-time cloud collaboration platforms are enhancing laser scanning efficiency and accessibility, reducing project timelines and costs. The integration of augmented reality (AR) and machine learning algorithms promises unprecedented precision in geospatial analysis, setting new industry standards beyond conventional surveying techniques.

Point Cloud Density

Laser scanning generates significantly higher point cloud density than traditional surveying methods, enabling more detailed and accurate 3D models for precise analysis and decision-making.

Georeferencing Accuracy

Laser scanning achieves higher georeferencing accuracy than traditional surveying by capturing dense spatial data with precise 3D coordinates and minimizing human error.

Terrestrial LiDAR

Terrestrial LiDAR offers higher accuracy, faster data collection, and detailed 3D modeling compared to traditional surveying methods, enhancing efficiency in topographic and structural assessments.

Photogrammetry

Laser scanning captures precise 3D data quickly, while traditional surveying with photogrammetry relies on overlapping images to create accurate spatial measurements but generally requires more processing time.

As-Built Documentation

Laser scanning provides faster, more accurate, and comprehensive as-built documentation compared to traditional surveying methods, significantly reducing data collection time and improving the precision of 3D building models.

Survey Control Networks

Laser scanning enhances survey control networks by providing high-density, accurate point clouds that reduce field time and improve data integration compared to the manual measurements and limited coverage of traditional surveying methods.

Reflectorless Measurement

Laser scanning with reflectorless measurement offers faster, more accurate data capture over traditional surveying by eliminating the need for physical targets and enabling remote surface detection.

Digital Elevation Model (DEM)

Laser scanning produces highly accurate and detailed Digital Elevation Models (DEMs) faster than traditional surveying, enabling superior terrain analysis and mapping precision.

Data Acquisition Speed

Laser scanning captures spatial data up to 10 times faster than traditional surveying methods, significantly reducing project timelines and increasing efficiency.

Topographic Mapping

Laser scanning provides highly accurate, detailed topographic mapping by rapidly capturing 3D surface data, surpassing the slower, less precise measurements of traditional surveying methods.

Laser Scanning vs Traditional Surveying Infographic

njnir.com

njnir.com