Precast concrete offers superior quality control and faster construction times due to factory fabrication, reducing site labor and weather-related delays. Cast-in-situ concrete provides enhanced adaptability on-site, allowing for complex shapes and modifications during construction that precast elements may not accommodate. Choosing between precast and cast-in-situ concrete depends on project-specific factors such as structural design, site conditions, and schedule constraints.

Table of Comparison

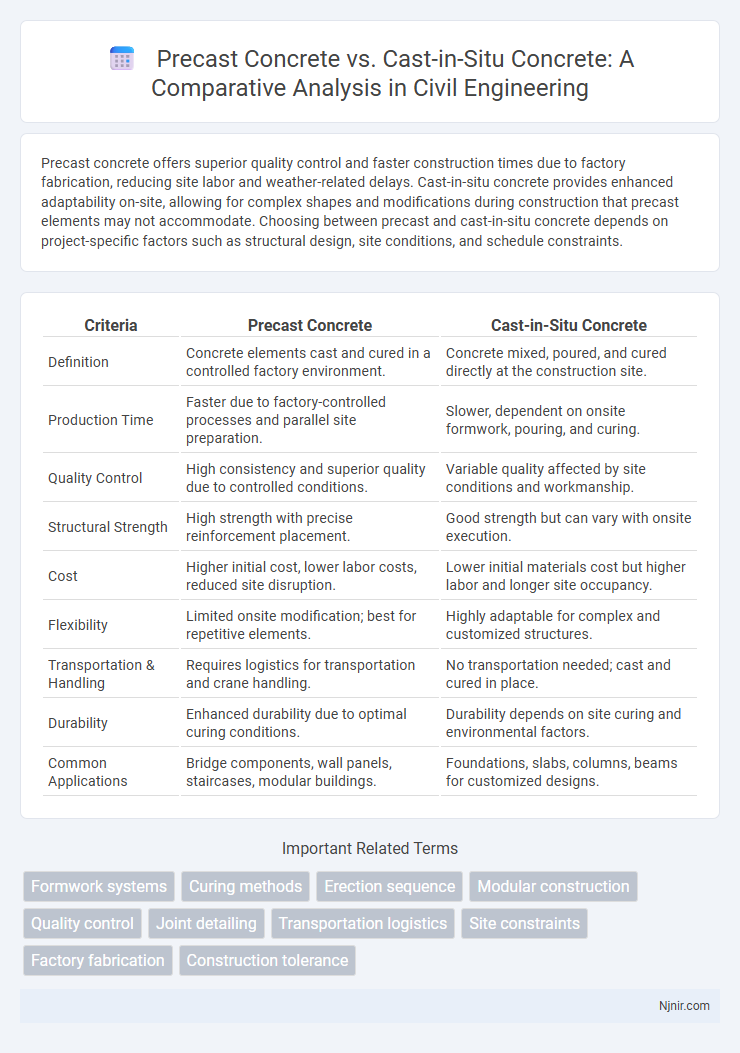

| Criteria | Precast Concrete | Cast-in-Situ Concrete |

|---|---|---|

| Definition | Concrete elements cast and cured in a controlled factory environment. | Concrete mixed, poured, and cured directly at the construction site. |

| Production Time | Faster due to factory-controlled processes and parallel site preparation. | Slower, dependent on onsite formwork, pouring, and curing. |

| Quality Control | High consistency and superior quality due to controlled conditions. | Variable quality affected by site conditions and workmanship. |

| Structural Strength | High strength with precise reinforcement placement. | Good strength but can vary with onsite execution. |

| Cost | Higher initial cost, lower labor costs, reduced site disruption. | Lower initial materials cost but higher labor and longer site occupancy. |

| Flexibility | Limited onsite modification; best for repetitive elements. | Highly adaptable for complex and customized structures. |

| Transportation & Handling | Requires logistics for transportation and crane handling. | No transportation needed; cast and cured in place. |

| Durability | Enhanced durability due to optimal curing conditions. | Durability depends on site curing and environmental factors. |

| Common Applications | Bridge components, wall panels, staircases, modular buildings. | Foundations, slabs, columns, beams for customized designs. |

Introduction to Precast and Cast-in-Situ Concrete

Precast concrete is manufactured in controlled factory environments, allowing for consistent quality, rapid installation, and reduced site labor, making it ideal for repetitive elements and large-scale projects. Cast-in-situ concrete is poured directly at the construction site, offering flexibility in shape and design adjustments, and is preferred for foundations, beams, and structures requiring monolithic strength. Both methods serve distinct structural and architectural needs, with precast emphasizing precision and speed, and cast-in-situ focusing on adaptability and integration.

Material Properties Comparison

Precast concrete exhibits superior quality control and uniformity due to factory production, resulting in higher strength, enhanced durability, and reduced permeability compared to cast-in-situ concrete. Cast-in-situ concrete allows for greater flexibility in shape and size but may suffer from variability in material properties influenced by onsite mixing and curing conditions. While precast concrete benefits from accelerated curing processes and controlled environment conditions that enhance compressive strength and reduce shrinkage, cast-in-situ exhibits better bonding characteristics with existing structures.

Construction Speed and Efficiency

Precast concrete significantly enhances construction speed by allowing simultaneous site preparation and component fabrication, reducing overall project timelines compared to cast-in-situ concrete. Factory-controlled conditions in precast production ensure higher quality and uniformity, minimizing on-site adjustments and labor requirements that prolong cast-in-situ processes. Efficient logistics and rapid assembly of precast elements contribute to lower labor costs and faster project completion, optimizing construction efficiency on commercial and infrastructure projects.

Quality Control and Assurance

Precast concrete offers superior quality control due to factory-controlled environments, ensuring consistent mix proportions, curing conditions, and dimensional accuracy. Cast-in-situ concrete quality heavily depends on on-site conditions such as weather, workmanship, and timely curing, often leading to variability in final strength and durability. Rigorous factory inspections and standardized production processes in precast concrete result in enhanced assurance of structural performance compared to the on-site variability challenges faced by cast-in-situ methods.

Cost Analysis and Budget Considerations

Precast concrete typically offers lower labor costs and reduced construction time, leading to cost savings in large-scale projects due to factory-controlled production and minimal on-site labor. Cast-in-situ concrete incurs higher on-site labor and formwork costs, with variable expenses linked to weather conditions and extended curing times impacting budget predictability. Budget considerations favor precast concrete for repetitive structural elements where economies of scale are achievable, while cast-in-situ concrete suits customized or complex geometries despite potentially higher overall costs.

Structural Performance and Durability

Precast concrete offers superior structural performance due to factory-controlled manufacturing conditions that ensure consistent quality and higher strength, while cast-in-situ concrete may experience variability caused by on-site factors. Durability in precast concrete is enhanced through precise curing processes and reduced exposure to environmental conditions during production, resulting in lower permeability and increased resistance to corrosion and freeze-thaw cycles. Cast-in-situ concrete's durability depends heavily on proper site curing and protection, with potential risks of cracking and moisture ingress affecting long-term structural integrity.

Flexibility in Design and Customization

Precast concrete offers limited flexibility in design and customization due to its factory-made nature, which requires molds and standardized processes. In contrast, cast-in-situ concrete allows for greater design adaptability on-site, accommodating complex shapes, varied sizes, and last-minute modifications. This flexibility makes cast-in-situ concrete preferable for projects needing unique architectural features or structural adjustments during construction.

Site Constraints and Logistic Challenges

Precast concrete offers significant advantages over cast-in-situ concrete in addressing site constraints by enabling off-site manufacturing, which reduces on-site construction time and minimizes space requirements for formwork and curing processes. The controlled factory environment of precast elements enhances quality consistency and mitigates weather-dependent delays common with cast-in-situ methods. However, precast concrete poses logistic challenges related to transportation and lifting of heavy components, requiring precise planning and specialized equipment to avoid site congestion and ensure timely installation.

Environmental Impact and Sustainability

Precast concrete reduces environmental impact through controlled factory production, enabling precise material usage and minimizing waste, while cast-in-situ concrete often generates higher on-site waste and requires more energy for curing. The sustainability of precast concrete is enhanced by its potential for recycling and reuse in modular construction, decreasing the demand for natural resources. Cast-in-situ concrete typically has a larger carbon footprint due to on-site processes and extended curing times that increase energy consumption and emissions.

Applications and Case Studies in Civil Engineering

Precast concrete is extensively utilized in repetitive structural elements such as bridge beams, tunnel segments, and building facades due to its enhanced quality control and accelerated construction timelines. Cast-in-situ concrete remains preferred for complex or monolithic structures like foundations, retaining walls, and customized slabs where on-site adaptability is crucial. Case studies in civil engineering highlight precast solutions in projects like the Millau Viaduct, demonstrating rapid assembly and durability, while cast-in-situ applications in the Burj Khalifa emphasize its structural versatility and formwork innovation.

Formwork systems

Precast concrete uses reusable steel or plastic formwork for factory casting, while cast-in-situ concrete requires on-site, often timber or plywood, formwork that is dismantled after curing.

Curing methods

Precast concrete cures under controlled factory conditions using steam curing or autoclaving for accelerated strength, while cast-in-situ concrete relies on on-site methods like water curing, plastic sheeting, or curing compounds to maintain moisture and ensure proper hydration.

Erection sequence

Precast concrete enables faster and more efficient erection sequences with factory-controlled manufacturing and on-site assembly, whereas cast-in-situ concrete requires extended curing time and formwork removal before proceeding to subsequent construction stages.

Modular construction

Precast concrete offers faster modular construction through factory-controlled production, enhancing quality and reducing onsite labor compared to the time-intensive, labor-heavy cast-in-situ concrete method.

Quality control

Precast concrete offers superior quality control through factory-controlled conditions and standardized production processes compared to cast-in-situ concrete, which is more susceptible to on-site variability and environmental factors.

Joint detailing

Precast concrete offers precise, factory-controlled joint detailing that ensures consistent alignment and minimizes on-site adjustments compared to the more variable and labor-intensive joint detailing in cast-in-situ concrete.

Transportation logistics

Precast concrete offers streamlined transportation logistics with standardized, controlled factory production enabling efficient loading, optimized routing, and reduced on-site handling compared to the bulky, time-sensitive transport challenges of cast-in-situ concrete.

Site constraints

Precast concrete reduces site constraints by minimizing on-site labor and curing time compared to cast-in-situ concrete, which requires extensive formwork and longer curing periods directly at the construction site.

Factory fabrication

Precast concrete, fabricated under controlled factory conditions, ensures higher quality, uniformity, and faster installation compared to cast-in-situ concrete mixed and poured directly on the construction site.

Construction tolerance

Precast concrete offers higher construction tolerance with factory-controlled precision, reducing site errors compared to the variability inherent in cast-in-situ concrete.

Precast concrete vs Cast-in-situ concrete Infographic

njnir.com

njnir.com