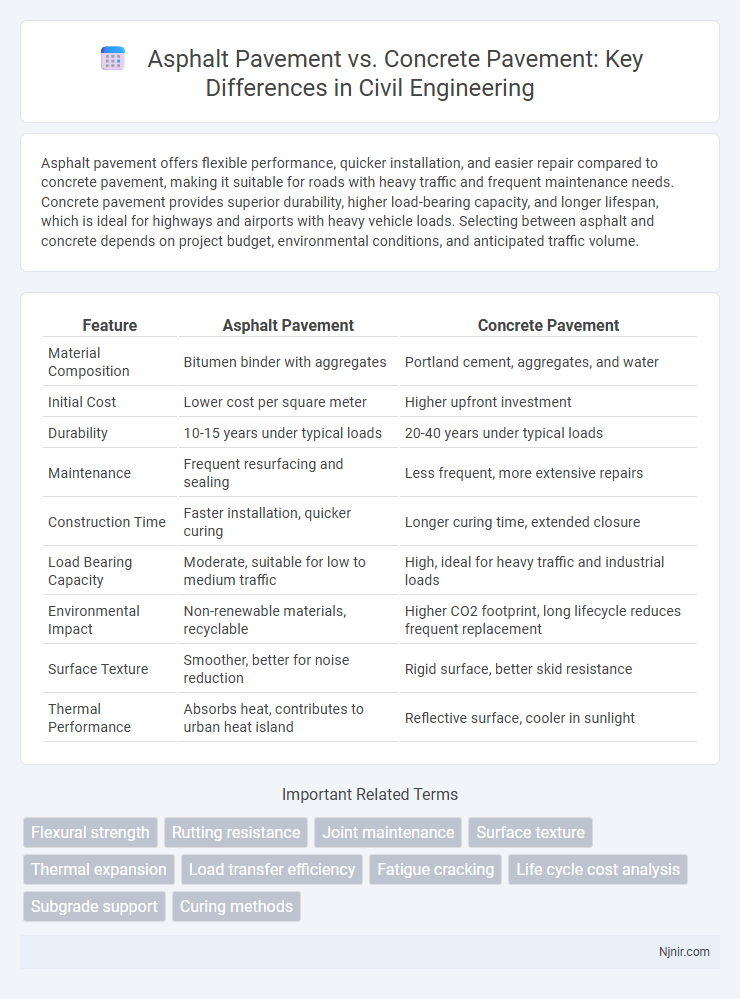

Asphalt pavement offers flexible performance, quicker installation, and easier repair compared to concrete pavement, making it suitable for roads with heavy traffic and frequent maintenance needs. Concrete pavement provides superior durability, higher load-bearing capacity, and longer lifespan, which is ideal for highways and airports with heavy vehicle loads. Selecting between asphalt and concrete depends on project budget, environmental conditions, and anticipated traffic volume.

Table of Comparison

| Feature | Asphalt Pavement | Concrete Pavement |

|---|---|---|

| Material Composition | Bitumen binder with aggregates | Portland cement, aggregates, and water |

| Initial Cost | Lower cost per square meter | Higher upfront investment |

| Durability | 10-15 years under typical loads | 20-40 years under typical loads |

| Maintenance | Frequent resurfacing and sealing | Less frequent, more extensive repairs |

| Construction Time | Faster installation, quicker curing | Longer curing time, extended closure |

| Load Bearing Capacity | Moderate, suitable for low to medium traffic | High, ideal for heavy traffic and industrial loads |

| Environmental Impact | Non-renewable materials, recyclable | Higher CO2 footprint, long lifecycle reduces frequent replacement |

| Surface Texture | Smoother, better for noise reduction | Rigid surface, better skid resistance |

| Thermal Performance | Absorbs heat, contributes to urban heat island | Reflective surface, cooler in sunlight |

Introduction to Asphalt and Concrete Pavements

Asphalt pavement consists of a flexible layer of bitumen-bound aggregates, offering rapid construction and easy maintenance, making it ideal for roads with frequent traffic changes. Concrete pavement features a rigid structure made of Portland cement, aggregates, and water, providing superior durability and load-bearing capacity, suitable for highways and heavy truck routes. Both materials require specialized design considerations based on climate, traffic load, and subgrade conditions to optimize performance and lifespan.

Material Composition and Properties

Asphalt pavement consists primarily of bitumen and aggregates, offering flexibility and excellent resistance to cracking under heavy traffic loads. Concrete pavement is composed of cement, water, and coarse aggregates, providing high compressive strength and durability with a rigid structure. The thermal expansion of concrete is higher, while asphalt exhibits better skid resistance and faster repair turnaround times.

Design Considerations for Pavement Selection

Asphalt pavement design prioritizes flexibility to accommodate temperature fluctuations and heavy traffic loads, making it suitable for regions with variable climates and frequent maintenance needs. Concrete pavement design emphasizes rigidity and high compressive strength, ideal for long-term durability and heavy axle loads in major highways or industrial areas. Selection depends on factors such as subgrade conditions, anticipated traffic volume, environmental exposure, and budget constraints, ensuring optimal performance and lifecycle cost efficiency.

Construction Methods and Techniques

Asphalt pavement construction involves laying hot-mix asphalt using paving machines, followed by compaction with rollers to achieve a smooth, flexible surface suitable for immediate use. Concrete pavement requires placing a cementitious mixture into forms, followed by finishing techniques such as screeding and troweling, and curing processes to enhance strength and durability. Asphalt offers faster installation with minimal curing time, whereas concrete demands longer setting periods but provides higher load-bearing capacity.

Cost Comparison: Initial and Lifecycle Analysis

Asphalt pavement generally offers lower initial installation costs, typically ranging from $2 to $5 per square foot, while concrete pavement installation costs range from $4 to $10 per square foot due to material and labor intensity. Lifecycle cost analysis reveals asphalt requires more frequent maintenance, such as sealcoating and patching every 3 to 5 years, causing cumulative costs that may surpass concrete's higher upfront expenses over 20-30 years. Concrete pavements, with lifespans of 30 to 40 years and reduced maintenance frequency, often present a more cost-effective solution for long-term infrastructure investments despite their higher initial price.

Performance and Durability Factors

Asphalt pavement offers flexibility and quicker installation, making it suitable for regions with temperature fluctuations, but it generally requires more frequent maintenance due to susceptibility to cracking and rutting. Concrete pavement is highly durable with a lifespan often exceeding 30 years, providing superior load-bearing capacity and resistance to heavy traffic, though it may face issues like surface scaling and joint deterioration over time. Performance differences arise from materials' thermal expansion properties and structural design, influencing long-term cost-efficiency and durability under varying environmental stressors.

Maintenance Requirements and Longevity

Asphalt pavement requires more frequent maintenance such as seal coating and patching every 3 to 5 years to prevent cracking and deterioration, with a typical lifespan of 15 to 20 years. Concrete pavement demands less frequent repairs, primarily joint sealing and occasional slab replacement, offering a longer service life of 30 to 40 years or more. The choice between asphalt and concrete significantly impacts long-term maintenance costs and durability based on traffic load and environmental conditions.

Environmental Impact and Sustainability

Asphalt pavement generally has a lower initial environmental impact due to its recyclability and lower energy consumption during production, while concrete pavement offers longer durability and reduced maintenance frequency, leading to lower lifecycle emissions. Warm-mix asphalt technologies further reduce greenhouse gas emissions by lowering production temperatures, whereas concrete's capacity for recycling and use of supplementary cementitious materials like fly ash enhances sustainability. Evaluating environmental impact involves considering factors such as embodied energy, urban heat island effect, and end-of-life recyclability, with asphalt excelling in recyclability and concrete providing longevity and high reflectivity that mitigates heat absorption.

Application Suitability and Use Cases

Asphalt pavement is ideal for applications requiring fast construction and easy maintenance, making it suitable for highways, airport runways, and urban roads with heavy traffic volume. Concrete pavement excels in high-load-bearing scenarios, such as industrial zones, ports, and bridges, due to its superior durability and resistance to heavy vehicles. Both materials cater to different environmental and economic conditions, influencing their use in climate-specific regions and budget constraints.

Future Trends in Pavement Technologies

Advancements in recycled materials and nanotechnology are revolutionizing asphalt pavement by enhancing durability and reducing environmental impact. Concrete pavement innovations emphasize ultra-high-performance concrete (UHPC) and 3D printing techniques to improve lifespan and reduce maintenance costs. Smart sensor integration for real-time monitoring and adaptive responses is becoming a key trend across both pavement types, promoting sustainable infrastructure management.

Flexural strength

Concrete pavement exhibits significantly higher flexural strength than asphalt pavement, enabling it to better resist bending stresses and heavy loads over time.

Rutting resistance

Concrete pavement exhibits superior rutting resistance compared to asphalt pavement due to its higher stiffness and durability under heavy traffic loads.

Joint maintenance

Asphalt pavement requires more frequent joint maintenance due to its flexibility and susceptibility to cracking, while concrete pavement joints typically demand less frequent maintenance but involve more complex sealing processes to prevent water infiltration and extend pavement life.

Surface texture

Asphalt pavement typically offers a smoother surface texture with better skid resistance than concrete pavement, which often features a rougher texture prone to crack formation.

Thermal expansion

Asphalt pavement exhibits lower thermal expansion compared to concrete pavement, reducing the risk of cracking and deformation under temperature fluctuations.

Load transfer efficiency

Concrete pavement exhibits superior load transfer efficiency due to its rigid jointed slabs distributing loads evenly, whereas asphalt pavement relies on the flexibility of its layers, resulting in comparatively lower load transfer performance.

Fatigue cracking

Asphalt pavement experiences fatigue cracking due to repetitive traffic loading and environmental factors, whereas concrete pavement resists fatigue cracking better but may develop joint or slab cracking under similar stress conditions.

Life cycle cost analysis

Asphalt pavement typically offers lower initial construction costs but higher maintenance expenses over time, while concrete pavement requires higher upfront investment with reduced maintenance costs, making its life cycle cost potentially lower in long-term applications.

Subgrade support

Concrete pavement provides superior subgrade support due to its higher rigidity and load distribution capabilities compared to the more flexible asphalt pavement.

Curing methods

Concrete pavement requires careful moisture curing for 7 to 14 days to achieve optimal strength and durability, whereas asphalt pavement relies on proper compaction and cooling without a curing process.

asphalt pavement vs concrete pavement Infographic

njnir.com

njnir.com