Post-tensioning and pre-tensioning are both methods of applying tension to steel tendons in concrete, enhancing its strength and durability. Post-tensioning involves tensioning the tendons after the concrete has cured, allowing for greater control over stress distribution and enabling thinner slabs in construction. Pre-tensioning, on the other hand, tensions the steel tendons before the concrete is cast, providing high initial compressive forces but is generally limited to precast elements and shorter spans.

Table of Comparison

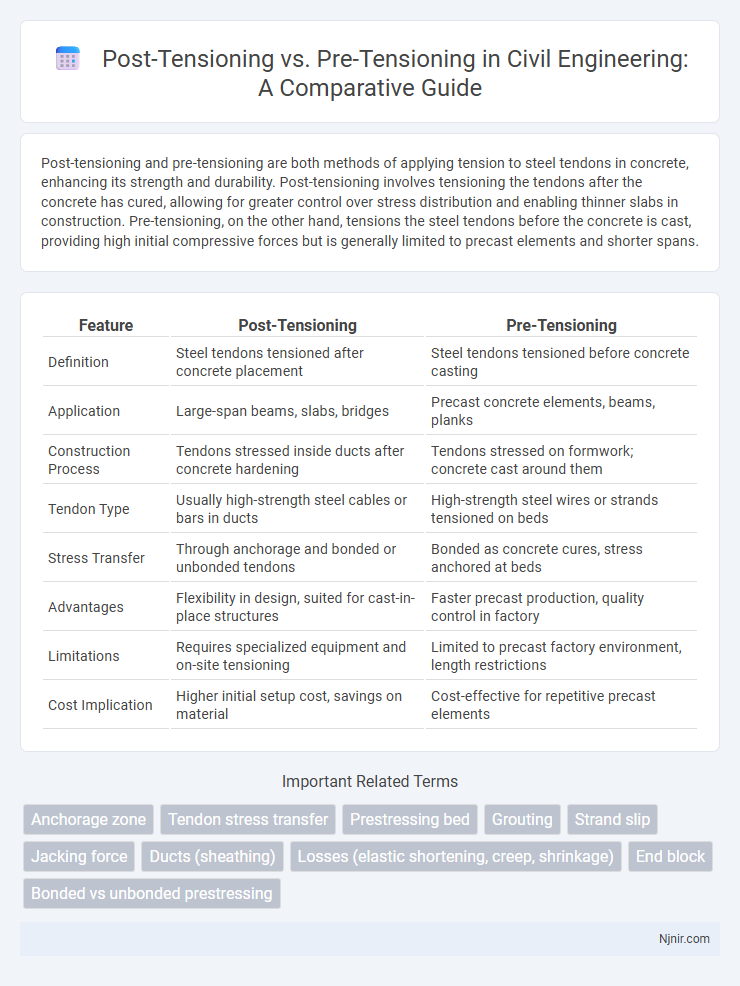

| Feature | Post-Tensioning | Pre-Tensioning |

|---|---|---|

| Definition | Steel tendons tensioned after concrete placement | Steel tendons tensioned before concrete casting |

| Application | Large-span beams, slabs, bridges | Precast concrete elements, beams, planks |

| Construction Process | Tendons stressed inside ducts after concrete hardening | Tendons stressed on formwork; concrete cast around them |

| Tendon Type | Usually high-strength steel cables or bars in ducts | High-strength steel wires or strands tensioned on beds |

| Stress Transfer | Through anchorage and bonded or unbonded tendons | Bonded as concrete cures, stress anchored at beds |

| Advantages | Flexibility in design, suited for cast-in-place structures | Faster precast production, quality control in factory |

| Limitations | Requires specialized equipment and on-site tensioning | Limited to precast factory environment, length restrictions |

| Cost Implication | Higher initial setup cost, savings on material | Cost-effective for repetitive precast elements |

Introduction to Post-Tensioning and Pre-Tensioning

Post-tensioning and pre-tensioning are two key methods in prestressed concrete construction that enhance structural performance by introducing internal stresses to counteract external loads. Pre-tensioning involves tensioning steel tendons before concrete is cast, allowing the concrete to bond firmly once it hardens, while post-tensioning applies tension to steel tendons after the concrete has gained sufficient strength, using anchorage systems to maintain stress. Both techniques improve concrete durability, enable longer spans, and reduce material usage compared to conventional reinforced concrete.

Fundamental Principles and Mechanisms

Post-tensioning involves applying tension to steel tendons after concrete has hardened, using hydraulic jacks to induce compressive stresses that counteract tensile forces, enhancing structural capacity and reducing cracking. In contrast, pre-tensioning stretches the steel tendons before concrete placement, transferring stress to the concrete upon curing and release, which improves load-bearing performance. Both methods optimize concrete strength by controlling internal stresses but differ in timing, tendon anchorage, and construction sequencing.

Material Requirements and Selection

Post-tensioning requires high-strength steel tendons that are tensioned after concrete has cured, allowing for thinner slabs and reduced concrete volume compared to pre-tensioning. Pre-tensioning uses steel strands tensioned before concrete placement, necessitating durable anchorage and sufficient bond strength between steel and concrete to transfer stresses effectively. Material selection in post-tensioning often favors corrosion-resistant coatings for tendons due to exposure risks, whereas pre-tensioned elements benefit from uniform steel quality and consistent concrete properties to ensure reliable load transfer.

Construction Processes and Techniques

Post-tensioning involves placing ducts within concrete forms and tensioning steel cables after the concrete has hardened, allowing for precise control of compression forces and enhanced structural capacity. Pre-tensioning requires tensioning steel tendons on a casting bed before pouring concrete, transferring stress to the concrete upon curing and release, which is ideal for repetitive precast elements. Both techniques optimize concrete performance but differ in application timing, equipment needs, and suitability for specific construction projects.

Structural Performance and Load Distribution

Post-tensioning enhances structural performance by allowing precise control of tension forces after concrete curing, resulting in improved crack resistance and better load distribution across beams and slabs. Pre-tensioning applies tension to steel tendons before concrete placement, providing high initial strength but with less flexibility in adjusting stresses after curing. Post-tensioned structures typically achieve greater material efficiency and adaptability under dynamic loads compared to pre-tensioned systems.

Applications in Civil Engineering Projects

Post-tensioning techniques are widely used in large-span bridges, parking structures, and high-rise buildings to allow for thinner slabs and longer spans with fewer supports. Pre-tensioning is predominantly applied in precast concrete elements such as beams, sleepers, and pipes where controlled conditions ensure optimal tendon placement and tensioning before casting. Both methods enhance structural performance by improving load distribution and reducing cracking, but post-tensioning offers greater flexibility for on-site adjustments in complex civil engineering projects.

Advantages and Disadvantages of Each Method

Post-tensioning offers superior load control and flexibility during construction, allowing longer spans and thinner slabs, but it requires specialized equipment and skilled labor, increasing initial costs. Pre-tensioning provides high-quality, factory-controlled reinforcement with faster production rates and reduced site labor, yet it limits design flexibility and can be unsuitable for on-site adaptations or longer structural elements. Both methods enhance concrete strength and durability, but selecting between them depends on project scale, complexity, and cost considerations.

Cost Considerations and Economic Factors

Post-tensioning typically involves higher initial setup costs due to specialized materials and on-site tensioning equipment, but it offers long-term savings through reduced structural weight and increased design flexibility. Pre-tensioning incurs lower manufacturing costs by producing tendons under controlled factory conditions, allowing for mass production efficiencies, which generally results in lower overall expenses for standard precast elements. Economic factors such as project scale, construction timeline, and labor availability heavily influence the cost-effectiveness of each method, with post-tensioning often favored for complex or large-span applications while pre-tensioning suits repetitive, high-volume production.

Durability, Maintenance, and Longevity

Post-tensioning offers enhanced durability by allowing for better crack control and reduced corrosion risk due to post-installed tendons being encased in grout. Pre-tensioning provides consistent tendon tensioning in controlled factory environments, ensuring uniform strand protection from environmental factors and lower maintenance requirements. Longevity of post-tensioned structures benefits from in-situ adjustments and repairs, while pre-tensioned elements often exhibit superior initial strength and durability from precise pre-tension application.

Recent Innovations and Future Trends

Recent innovations in post-tensioning include the development of more corrosion-resistant materials and advanced monitoring systems that enhance structural safety and longevity. In pre-tensioning, automation and robotic tensioning machines have improved precision and efficiency, promoting faster construction timelines. Future trends focus on integrating smart sensors and AI-driven analytics in both methods to optimize performance and predictive maintenance throughout the lifespan of concrete structures.

Anchorage zone

Post-tensioning anchorage zones experience higher localized stresses due to on-site tensioning of tendons, whereas pre-tensioning anchorage zones embed tendons during casting, resulting in more uniform stress distribution.

Tendon stress transfer

Post-tensioning transfers tendon stress after concrete has hardened, enabling immediate load-bearing capacity, while pre-tensioning transfers tendon stress before casting, relying on bond strength between tendons and concrete.

Prestressing bed

Post-tensioning involves tensioning the steel tendons after concrete has hardened, eliminating the need for a prestressing bed, whereas pre-tensioning requires a prestressing bed to tension the steel tendons before concrete placement.

Grouting

Grouting in post-tensioning is essential for corrosion protection and bond strength between tendons and concrete, whereas pre-tensioning typically does not require grouting since tendons are cast-in-place and fully bonded within the concrete matrix.

Strand slip

Strand slip in post-tensioning is a critical concern requiring specialized anchorage systems to prevent movement, whereas pre-tensioning involves fixed strands cast into concrete, eliminating strand slip risk.

Jacking force

Post-tensioning requires applying jacking force after concrete hardening, whereas pre-tensioning applies jacking force before concrete casting to induce tensile stress in the tendons.

Ducts (sheathing)

Ducts in post-tensioning are typically corrugated and flexible to allow tendon movement during stressing, whereas pre-tensioning uses smooth, rigid sheathing fixed in place before concrete casting to maintain tendon position.

Losses (elastic shortening, creep, shrinkage)

Post-tensioning experiences lower losses from elastic shortening compared to pre-tensioning, but both methods are affected by creep and shrinkage, with post-tensioning generally allowing better compensation for these losses during stressing.

End block

End blocks in post-tensioning systems serve as critical anchorage points to transfer tendon forces to concrete, whereas pre-tensioning end blocks primarily support the pre-stressed tendons before concrete casting and have different design requirements due to tendon placement.

Bonded vs unbonded prestressing

Bonded post-tensioning involves permanently anchoring prestressing tendons within concrete using grout that enhances load transfer and corrosion protection, while unbonded prestressing features tendons coated with grease and encased in plastic sheaths allowing free movement, offering easier replacement but less structural redundancy.

post-tensioning vs pre-tensioning Infographic

njnir.com

njnir.com