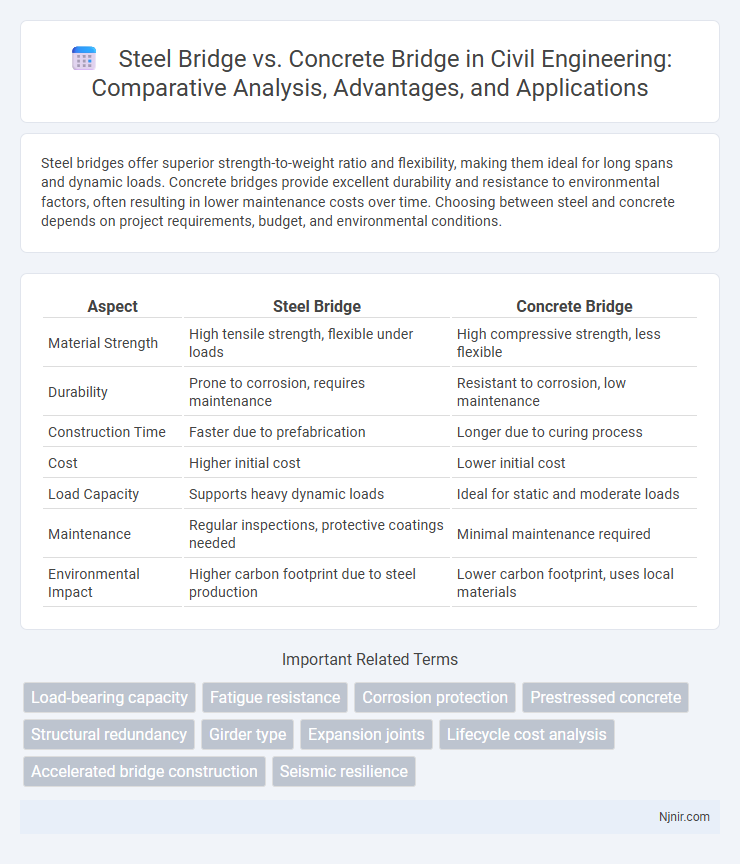

Steel bridges offer superior strength-to-weight ratio and flexibility, making them ideal for long spans and dynamic loads. Concrete bridges provide excellent durability and resistance to environmental factors, often resulting in lower maintenance costs over time. Choosing between steel and concrete depends on project requirements, budget, and environmental conditions.

Table of Comparison

| Aspect | Steel Bridge | Concrete Bridge |

|---|---|---|

| Material Strength | High tensile strength, flexible under loads | High compressive strength, less flexible |

| Durability | Prone to corrosion, requires maintenance | Resistant to corrosion, low maintenance |

| Construction Time | Faster due to prefabrication | Longer due to curing process |

| Cost | Higher initial cost | Lower initial cost |

| Load Capacity | Supports heavy dynamic loads | Ideal for static and moderate loads |

| Maintenance | Regular inspections, protective coatings needed | Minimal maintenance required |

| Environmental Impact | Higher carbon footprint due to steel production | Lower carbon footprint, uses local materials |

Introduction to Steel and Concrete Bridges

Steel bridges offer exceptional strength-to-weight ratios, enabling longer spans and flexible design options for dynamic loads and seismic activity. Concrete bridges provide high durability and low maintenance costs, ideal for heavy traffic and harsh environmental conditions due to their resistance to corrosion and fire. Both materials are often combined in hybrid structures to optimize performance, cost-efficiency, and lifespan in modern bridge construction.

Material Properties and Performance

Steel bridges offer high tensile strength and excellent flexibility, making them ideal for long spans and dynamic loads, while their lightweight nature reduces foundation requirements. Concrete bridges provide exceptional compressive strength and durability, excelling in resistance to weathering and corrosion, especially reinforced or prestressed concrete variants. Performance-wise, steel requires regular maintenance to prevent rust, whereas concrete structures tend to have longer lifespans with lower upkeep costs under similar environmental conditions.

Design Flexibility and Aesthetic Appeal

Steel bridges offer superior design flexibility due to their high strength-to-weight ratio, allowing for longer spans and complex architectural shapes that enhance aesthetic appeal. Concrete bridges provide robust durability and can be molded into various forms, but they often result in heavier structures with more limited design creativity compared to steel. The choice between steel and concrete significantly impacts the visual and structural possibilities of bridge projects, influencing both functionality and artistic expression.

Construction Techniques and Speed

Steel bridges benefit from prefabrication methods, allowing components to be manufactured off-site and assembled rapidly on location, significantly reducing construction time. Concrete bridges often require on-site casting and curing, which extends the construction period but allows for customized, complex shapes and greater adaptability to site conditions. The choice between steel and concrete bridges heavily influences project timelines due to their distinct construction techniques and material handling.

Structural Durability and Longevity

Steel bridges exhibit superior tensile strength and flexibility, allowing them to withstand dynamic loads and seismic activities effectively, which significantly enhances structural durability. Concrete bridges offer excellent compressive strength and resistance to corrosion, especially when utilizing reinforced or prestressed concrete, contributing to their long service life in harsh environmental conditions. Both materials require proper maintenance; however, concrete bridges typically demonstrate longer longevity due to less susceptibility to fatigue and environmental degradation when designed for durable performance.

Maintenance Requirements and Costs

Steel bridges typically demand more frequent maintenance due to susceptibility to corrosion, requiring regular inspections, painting, and repairs to prevent rust and structural degradation. Concrete bridges generally incur lower maintenance costs, as they resist corrosion better but may require occasional crack sealing and surface treatments to address wear and environmental effects. Over the bridge lifecycle, steel bridges often exhibit higher cumulative maintenance expenses, whereas concrete bridges provide more cost-effective durability in long-term infrastructure management.

Load-Bearing Capacity and Applications

Steel bridges offer superior load-bearing capacity due to their high strength-to-weight ratio, making them ideal for long-span structures and heavy traffic loads such as highways and railways. Concrete bridges provide excellent compressive strength and durability, suiting them for shorter spans and applications like pedestrian bridges, overpasses, and urban infrastructure. The choice between steel and concrete bridges depends on factors including span length, load requirements, environmental conditions, and maintenance considerations.

Environmental Impact and Sustainability

Steel bridges typically have a higher embodied energy due to energy-intensive manufacturing processes but offer advantages in recyclability and lower maintenance requirements, contributing to long-term sustainability. Concrete bridges, while generally producing more CO2 emissions during cement production, benefit from using locally sourced materials and advancements in low-carbon concrete mixtures that reduce their environmental footprint. Both materials require careful lifecycle assessment to optimize environmental impact, with steel favoring reuse and recyclability and concrete emphasizing durability and carbon capture potential through mineralization over time.

Initial Investment and Lifecycle Economics

Steel bridges typically require a higher initial investment due to material costs and fabrication complexity, but offer faster construction times and reduced labor expenses. Concrete bridges often have lower upfront costs but may incur higher maintenance expenses over their lifecycle due to susceptibility to cracking and environmental damage. Evaluating lifecycle economics, steel bridges provide superior durability and easier repairs, leading to potentially lower total costs despite higher initial outlays.

Future Trends in Bridge Engineering

Future trends in bridge engineering emphasize the integration of smart materials and advanced construction techniques for both steel and concrete bridges. Steel bridges are evolving with innovations like ultra-high-performance steel and modular construction, enhancing durability and reducing maintenance costs. Concrete bridges benefit from developments in ultra-high-performance concrete and 3D printing technology, improving load capacity and speeding up project timelines while ensuring sustainability.

Load-bearing capacity

Steel bridges offer higher load-bearing capacity due to superior tensile strength and flexibility compared to concrete bridges.

Fatigue resistance

Steel bridges exhibit superior fatigue resistance compared to concrete bridges due to steel's higher tensile strength and flexibility under cyclic loading conditions.

Corrosion protection

Steel bridges require advanced corrosion protection methods such as galvanization, painting, or cathodic protection systems to prevent rust, whereas concrete bridges rely on embedded steel reinforcement with concrete cover and additives like corrosion inhibitors to minimize corrosion risk.

Prestressed concrete

Prestressed concrete bridges offer enhanced durability and reduced maintenance compared to steel bridges by minimizing tensile stresses and improving load-bearing capacity.

Structural redundancy

Steel bridges offer higher structural redundancy than concrete bridges due to their interconnected steel components that provide multiple load paths and enhanced resilience against localized failures.

Girder type

Steel girder bridges offer higher strength-to-weight ratios and longer spans compared to concrete girder bridges, which provide better durability and lower maintenance costs.

Expansion joints

Steel bridges require more frequent and flexible expansion joints than concrete bridges due to higher thermal expansion rates and structural movement.

Lifecycle cost analysis

Steel bridges typically have lower initial costs but higher maintenance expenses, while concrete bridges incur higher upfront costs with lower long-term maintenance, making concrete bridges more cost-effective over a 50-year lifecycle analysis.

Accelerated bridge construction

Steel bridges enable accelerated bridge construction through prefabrication and rapid assembly, significantly reducing onsite construction time compared to conventional concrete bridges.

Seismic resilience

Steel bridges exhibit superior seismic resilience compared to concrete bridges due to their higher ductility and ability to absorb and dissipate energy during earthquakes.

steel bridge vs concrete bridge Infographic

njnir.com

njnir.com