Geopolymer cement offers superior environmental benefits compared to Portland cement by significantly reducing carbon dioxide emissions during production. It exhibits enhanced chemical resistance and durability, making it ideal for aggressive environments and infrastructure projects requiring longevity. The use of industrial by-products such as fly ash in geopolymer cement also promotes sustainable construction practices while maintaining comparable mechanical strength to traditional Portland cement.

Table of Comparison

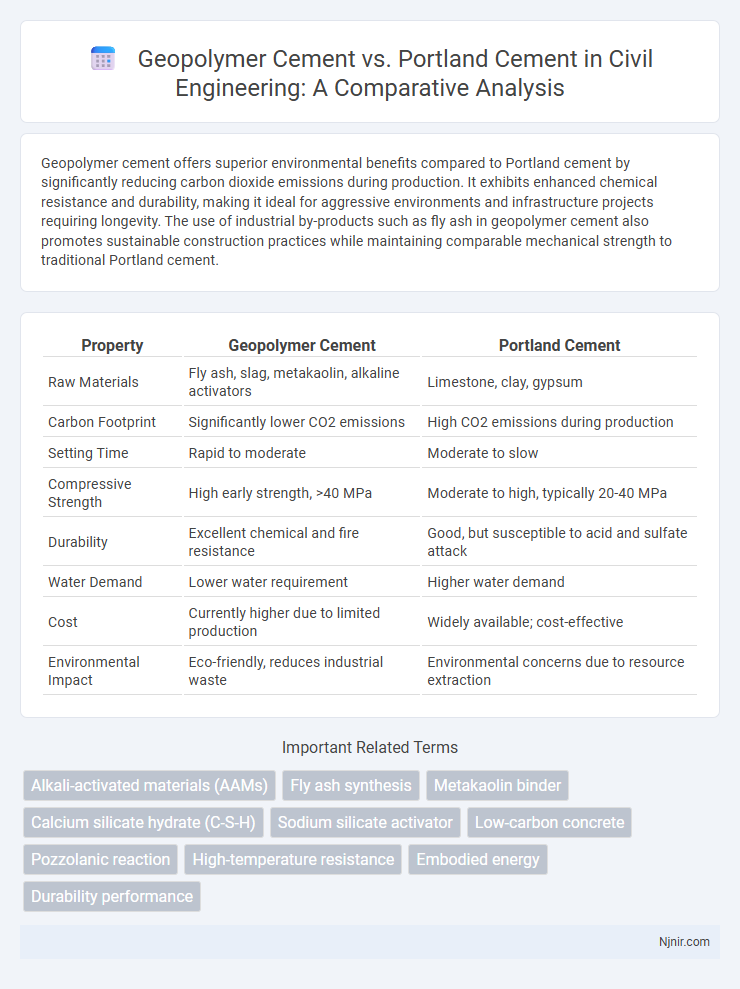

| Property | Geopolymer Cement | Portland Cement |

|---|---|---|

| Raw Materials | Fly ash, slag, metakaolin, alkaline activators | Limestone, clay, gypsum |

| Carbon Footprint | Significantly lower CO2 emissions | High CO2 emissions during production |

| Setting Time | Rapid to moderate | Moderate to slow |

| Compressive Strength | High early strength, >40 MPa | Moderate to high, typically 20-40 MPa |

| Durability | Excellent chemical and fire resistance | Good, but susceptible to acid and sulfate attack |

| Water Demand | Lower water requirement | Higher water demand |

| Cost | Currently higher due to limited production | Widely available; cost-effective |

| Environmental Impact | Eco-friendly, reduces industrial waste | Environmental concerns due to resource extraction |

Introduction to Geopolymer and Portland Cement

Geopolymer cement is an innovative, eco-friendly material composed of aluminosilicate-rich substances activated by alkaline solutions, offering reduced carbon emissions compared to traditional Portland cement. Portland cement, the conventional binder in concrete production, is primarily made from limestone and clay calcined at high temperatures, resulting in significant CO2 output during manufacturing. The shift towards geopolymer cement is driven by its superior chemical resistance, lower environmental impact, and potential for sustainable construction practices.

Chemical Composition and Formation

Geopolymer cement primarily consists of aluminosilicate materials activated by alkaline solutions like sodium hydroxide and sodium silicate, forming a three-dimensional polymeric chain structure through polycondensation. Portland cement mainly comprises calcium silicates such as tricalcium silicate (C3S) and dicalcium silicate (C2S), which hydrate to produce calcium silicate hydrate (C-S-H) gel responsible for its strength. The chemical formation of geopolymer cement involves alkali activation and polymerization, whereas Portland cement relies on hydration reactions of calcium silicates.

Production Processes and Raw Materials

Geopolymer cement is produced through the alkaline activation of industrial byproducts such as fly ash and slag, utilizing less energy and emitting significantly lower CO2 compared to Portland cement, which relies on the calcination of limestone and clay at high temperatures around 1450degC. The raw materials for geopolymer cement primarily include aluminosilicate sources and alkaline activators like sodium hydroxide and sodium silicate, whereas Portland cement requires abundant natural resources like limestone, shale, and sand. The innovative production process of geopolymer cement promotes waste valorization and sustainability, contrasting with Portland cement's reliance on intensive mining and thermal processing.

Mechanical Properties and Strength

Geopolymer cement exhibits superior compressive strength and enhanced resistance to chemical and thermal degradation compared to Portland cement, making it ideal for high-performance construction applications. Its mechanical properties include higher tensile and flexural strength due to the dense microstructure formed during polymerization, resulting in increased durability and reduced cracking. Portland cement, while widely used, typically shows lower mechanical strength and slower strength gain, particularly under aggressive environmental conditions.

Durability and Chemical Resistance

Geopolymer cement exhibits superior durability compared to Portland cement due to its enhanced resistance to sulfate attack, acid corrosion, and high-temperature exposure, resulting in longer service life in harsh environments. The chemical composition of geopolymer binders, primarily aluminosilicate materials activated by alkaline solutions, imparts excellent resistance to chlorides and aggressive chemicals, reducing the risk of reinforcement corrosion. Studies show that geopolymer concrete maintains structural integrity and mechanical properties better than traditional Portland cement under aggressive chemical exposures, making it ideal for applications in wastewater treatment plants, marine structures, and chemical industries.

Environmental Impact and Carbon Footprint

Geopolymer cement significantly reduces carbon footprint by utilizing industrial byproducts like fly ash and slag, which decreases CO2 emissions by up to 80% compared to Portland cement manufacturing. Portland cement production is responsible for approximately 8% of global CO2 emissions due to the calcination of limestone and energy-intensive kiln processes. The lower energy consumption and sustainable raw materials in geopolymer cement contribute to its superior environmental impact profile, making it a promising eco-friendly alternative.

Cost Efficiency and Economic Comparison

Geopolymer cement offers significant cost savings over Portland cement due to lower energy consumption and the use of industrial byproducts like fly ash or slag, reducing raw material expenses. Economic comparisons reveal geopolymer cement's potential to decrease carbon taxes and long-term maintenance costs thanks to its enhanced durability and chemical resistance. Despite higher initial material costs in some cases, geopolymer cement's overall life-cycle cost efficiency often outperforms traditional Portland cement in sustainable construction projects.

Applications in Civil Engineering Projects

Geopolymer cement offers superior resistance to chemical attacks and high temperatures, making it ideal for industrial flooring, wastewater treatment plants, and refractory linings in civil engineering projects. Portland cement remains widely used for structural applications such as bridges, buildings, and pavements due to its well-established standards, cost-effectiveness, and reliable compressive strength. Geopolymer concrete's low carbon footprint and durability provide sustainable alternatives in infrastructure development, especially in environmentally sensitive projects.

Standards, Codes, and Regulatory Acceptance

Geopolymer cement is gaining recognition through emerging standards like ASTM C1157 and ISO 22965, which address its unique chemical and mechanical properties distinct from Portland cement's well-established ASTM C150 specifications. Regulatory acceptance varies globally, with progressive regions incorporating geopolymer cement in green building codes due to its lower carbon footprint, while Portland cement remains dominant under traditional codes like Eurocode 2 and ACI 318. The adaptation of standards and codes is critical for widespread implementation, influencing construction approvals, material testing protocols, and structural design methodologies.

Future Trends and Innovations in Cement Technology

Geopolymer cement is gaining momentum due to its lower carbon footprint and superior resistance to chemicals and high temperatures compared to traditional Portland cement. Innovations in nanotechnology and eco-friendly raw materials are driving the development of geopolymer cements with enhanced durability and faster setting times. Future trends indicate a shift towards sustainable construction materials, with increased adoption of geopolymer cements in infrastructure projects aiming to reduce greenhouse gas emissions in the cement industry.

Alkali-activated materials (AAMs)

Alkali-activated materials (AAMs) used in geopolymer cement offer superior durability, lower carbon emissions, and enhanced chemical resistance compared to traditional Portland cement.

Fly ash synthesis

Fly ash-based geopolymer cement synthesis involves activating fly ash with alkaline solutions to produce a sustainable binder with lower carbon emissions compared to traditional Portland cement.

Metakaolin binder

Metakaolin-based geopolymer cement exhibits superior chemical resistance, lower carbon emissions, and enhanced thermal stability compared to traditional Portland cement.

Calcium silicate hydrate (C-S-H)

Geopolymer cement forms calcium silicate hydrate (C-S-H) with lower calcium content and enhanced durability compared to the high-calcium C-S-H gel predominantly produced in Portland cement hydration.

Sodium silicate activator

Sodium silicate activator in geopolymer cement enhances early strength development and chemical resistance compared to traditional Portland cement.

Low-carbon concrete

Geopolymer cement produces significantly lower carbon emissions than Portland cement, making it a sustainable choice for low-carbon concrete applications.

Pozzolanic reaction

Geopolymer cement utilizes a pozzolanic reaction by activating aluminosilicate materials with alkaline solutions to form a durable, eco-friendly binder, whereas Portland cement relies on the hydration of calcium silicates for strength development.

High-temperature resistance

Geopolymer cement exhibits superior high-temperature resistance compared to Portland cement, maintaining structural integrity and strength beyond 800degC due to its stable aluminosilicate matrix.

Embodied energy

Geopolymer cement typically has 40-80% lower embodied energy compared to traditional Portland cement, significantly reducing carbon emissions during production.

Durability performance

Geopolymer cement exhibits superior durability performance compared to Portland cement due to its enhanced resistance to chemical attacks, lower permeability, and higher thermal stability.

Geopolymer cement vs Portland cement Infographic

njnir.com

njnir.com