Microtunneling offers precise, trenchless construction with minimal surface disruption, ideal for urban infrastructure projects requiring small-diameter pipelines. Pipe jacking involves pushing pipes through the ground using hydraulic jacks, suitable for larger diameter pipes but often requires more extensive excavation and setup. Both methods reduce environmental impact compared to traditional open-cut excavation, but microtunneling provides greater control and accuracy for complex alignments.

Table of Comparison

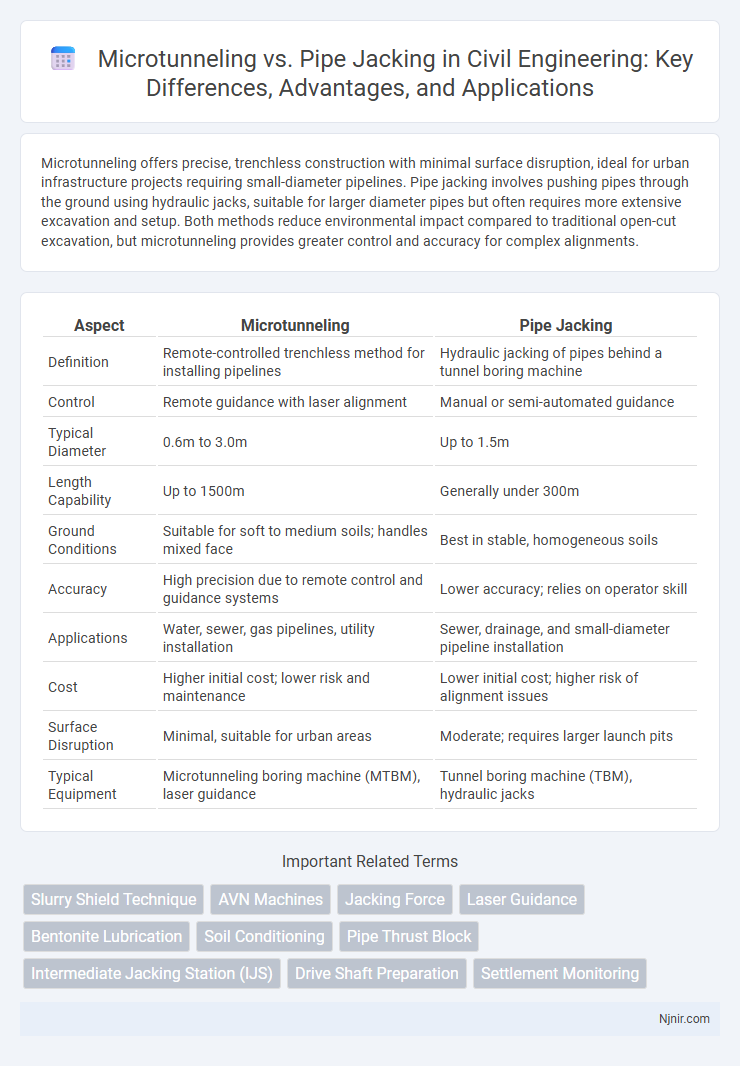

| Aspect | Microtunneling | Pipe Jacking |

|---|---|---|

| Definition | Remote-controlled trenchless method for installing pipelines | Hydraulic jacking of pipes behind a tunnel boring machine |

| Control | Remote guidance with laser alignment | Manual or semi-automated guidance |

| Typical Diameter | 0.6m to 3.0m | Up to 1.5m |

| Length Capability | Up to 1500m | Generally under 300m |

| Ground Conditions | Suitable for soft to medium soils; handles mixed face | Best in stable, homogeneous soils |

| Accuracy | High precision due to remote control and guidance systems | Lower accuracy; relies on operator skill |

| Applications | Water, sewer, gas pipelines, utility installation | Sewer, drainage, and small-diameter pipeline installation |

| Cost | Higher initial cost; lower risk and maintenance | Lower initial cost; higher risk of alignment issues |

| Surface Disruption | Minimal, suitable for urban areas | Moderate; requires larger launch pits |

| Typical Equipment | Microtunneling boring machine (MTBM), laser guidance | Tunnel boring machine (TBM), hydraulic jacks |

Introduction to Microtunneling and Pipe Jacking

Microtunneling and pipe jacking are trenchless construction techniques used for installing underground pipelines with minimal surface disruption. Microtunneling employs remotely controlled, guided boring machines to create small-diameter tunnels, ideal for precise alignment in urban or congested areas. Pipe jacking involves pushing pipes through the ground behind a shield or boring machine, commonly used for larger diameter pipes and longer distances in sewer and utility installations.

Fundamental Principles of Microtunneling

Microtunneling operates on the principle of remote-controlled, guided pipe installation using a microtunnel boring machine (MTBM) that simultaneously excavates and installs pipes in small-diameter tunnels, typically less than 3 meters in diameter. This trenchless technology relies on a shielded boring machine with a slurry or dry excavation system to stabilize the tunnel face and minimize ground settlement. Precise guidance systems and hydraulic jacking ensure accurate alignment and controlled pipe jacking pressure throughout the process to maintain tunnel integrity.

Pipe Jacking: Technique and Process Overview

Pipe jacking is a trenchless construction technique that involves pushing pipes through the ground using hydraulic jacks from a launch shaft to a reception shaft, minimizing surface disruption. This method typically uses pre-fabricated pipes assembled behind the jacking frame, allowing for precise control of alignment and gradient during installation. Pipe jacking is ideal for installing utilities like water, sewage, and gas pipelines under roads or urban areas where open-cut excavation is impractical.

Key Equipment Used in Microtunneling

Microtunneling primarily uses a remotely controlled microtunnel boring machine (MTBM) that integrates a shield, cutter head, and slurry or earth pressure balance system to excavate and maintain stability. Key equipment also includes laser guidance systems for precise steering, slurry separation plants for managing spoil, and hydraulic jacking rigs to advance the pipe segments through the bore. This setup contrasts with pipe jacking that often relies on manual guidance and simpler excavation methods, emphasizing mechanized precision and automated control in microtunneling operations.

Essential Machinery for Pipe Jacking Operations

Essential machinery for pipe jacking operations includes hydraulic jacks, which provide precise pushing force to install pipes underground with minimal surface disruption. A slurry excavation system is often integrated to remove spoil material efficiently while stabilizing the borehole. Guidance systems, such as laser or gyro-based technologies, ensure accurate alignment throughout the pipe jacking process, critical for successful underground pipeline installation.

Comparative Analysis: Microtunneling vs. Pipe Jacking

Microtunneling offers precise guidance and remote control, making it ideal for complex urban environments requiring minimal surface disruption, whereas pipe jacking involves pushing pipes from a launch shaft without direct control of the boring face, suitable for simpler, straighter alignments. Microtunneling systems use a microtunnel boring machine (MTBM) with laser guidance, enhancing accuracy and reducing ground settlement compared to pipe jacking, which relies on hydraulic jacks and manual steering. Both methods minimize excavation and surface impact, but microtunneling's automation and greater control typically result in higher installation costs offset by improved safety and precision.

Suitability for Different Soil and Site Conditions

Microtunneling is highly suitable for soft to medium soil conditions, such as silts, clays, and loose sands, where precise control and minimal surface disruption are essential, commonly used in urban areas with limited workspace. Pipe jacking excels in firmer soils, including dense sands and gravels, and can efficiently handle moderate obstructions, making it ideal for longer drives and straightforward alignments with ample entry and reception shafts. Selecting between microtunneling and pipe jacking depends on specific soil stability, groundwater conditions, and site constraints to ensure optimal trenchless installation performance.

Project Cost and Economic Considerations

Microtunneling typically incurs higher initial project costs due to specialized equipment and remote operation requirements, but offers precise alignment and reduced surface disruption, potentially lowering indirect expenses. Pipe jacking involves lower upfront investment with simpler machinery, making it economically viable for shorter distances and less complex soil conditions. Evaluating total project cost requires analyzing soil type, tunnel length, and risk factors to determine the most cost-efficient method for a given infrastructure effort.

Environmental Impact and Risk Management

Microtunneling and pipe jacking differ significantly in environmental impact and risk management, with microtunneling generally causing less surface disruption due to its remote-controlled operation beneath sensitive sites. The process employs precision guidance systems that reduce the risk of utility strikes and limit soil displacement, thereby minimizing ecosystem disturbance and groundwater contamination. Pipe jacking, while effective for larger diameters, may pose higher risks of ground subsidence and surface settlement, necessitating robust monitoring and mitigation strategies to manage potential environmental hazards.

Future Trends in Trenchless Technology

Microtunneling and pipe jacking are evolving with advancements in robotic guidance and real-time monitoring systems, enhancing precision and reducing environmental impact. Future trends emphasize automated excavation, integration of AI for predictive maintenance, and the use of sustainable materials to increase durability and efficiency. The adoption of smart sensors and data analytics is set to transform trenchless construction management, optimizing project timelines and cost-effectiveness.

Slurry Shield Technique

The Slurry Shield technique in microtunneling offers enhanced soil stabilization and reduced ground settlement compared to traditional pipe jacking by actively balancing earth pressure and removing excavated material with pressurized slurry.

AVN Machines

AVN machines enhance microtunneling by providing precise remote-controlled excavation and pipe installation capabilities, offering superior accuracy and reduced surface disruption compared to traditional pipe jacking methods.

Jacking Force

Microtunneling generally requires lower jacking force compared to pipe jacking due to its smaller diameter and automated guidance system, enhancing precision and reducing friction.

Laser Guidance

Microtunneling uses precise laser guidance systems for accurate alignment and grading, while pipe jacking relies primarily on mechanical methods with limited laser integration.

Bentonite Lubrication

Microtunneling uses bentonite lubrication to reduce friction and stabilize the tunnel face, while pipe jacking typically relies on bentonite slurry to minimize pipe-soil contact and ease pipe installation.

Soil Conditioning

Microtunneling requires advanced soil conditioning techniques to improve soil stability and reduce friction, whereas pipe jacking often relies on less intensive soil conditioning due to its use in more stable ground conditions.

Pipe Thrust Block

Pipe thrust blocks provide critical resistance against hydraulic forces during pipe jacking, enhancing stability and minimizing ground movement compared to microtunneling.

Intermediate Jacking Station (IJS)

The Intermediate Jacking Station (IJS) enhances productivity in microtunneling by reducing jacking forces over long distances, a feature less commonly employed in standard pipe jacking projects.

Drive Shaft Preparation

Drive shaft preparation in microtunneling requires precise alignment and structural reinforcement to accommodate the remote-controlled tunneling machine, whereas pipe jacking drive shafts prioritize robust construction for manual or semi-automated pushing of pipe segments.

Settlement Monitoring

Microtunneling provides more precise settlement monitoring through remote control and laser guidance, minimizing ground displacement compared to traditional pipe jacking methods.

Microtunneling vs Pipe jacking Infographic

njnir.com

njnir.com