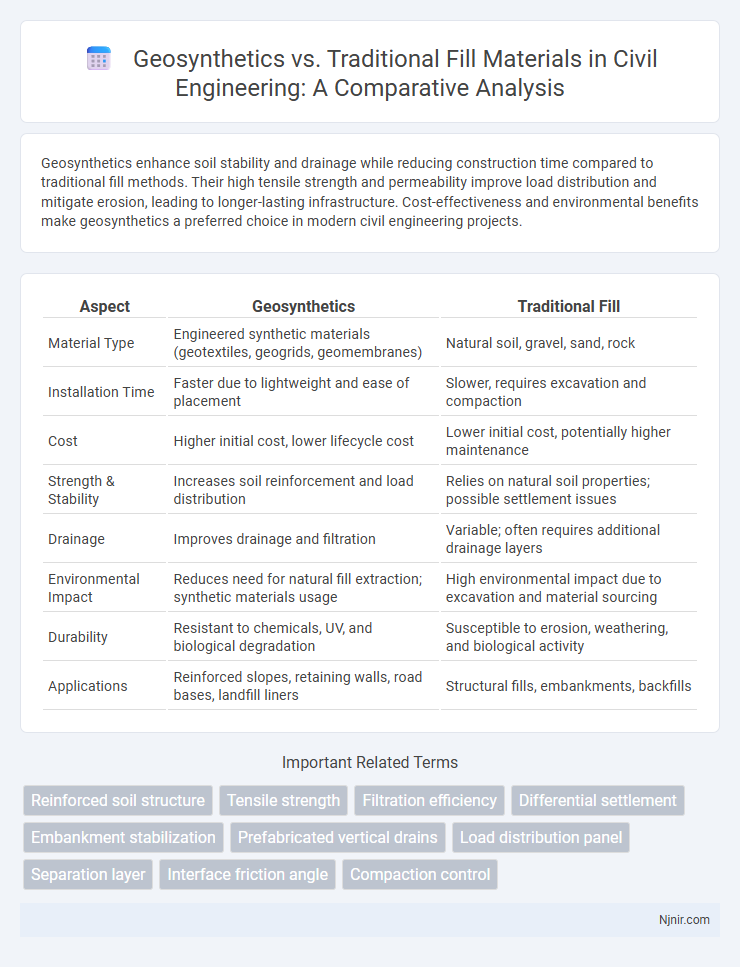

Geosynthetics enhance soil stability and drainage while reducing construction time compared to traditional fill methods. Their high tensile strength and permeability improve load distribution and mitigate erosion, leading to longer-lasting infrastructure. Cost-effectiveness and environmental benefits make geosynthetics a preferred choice in modern civil engineering projects.

Table of Comparison

| Aspect | Geosynthetics | Traditional Fill |

|---|---|---|

| Material Type | Engineered synthetic materials (geotextiles, geogrids, geomembranes) | Natural soil, gravel, sand, rock |

| Installation Time | Faster due to lightweight and ease of placement | Slower, requires excavation and compaction |

| Cost | Higher initial cost, lower lifecycle cost | Lower initial cost, potentially higher maintenance |

| Strength & Stability | Increases soil reinforcement and load distribution | Relies on natural soil properties; possible settlement issues |

| Drainage | Improves drainage and filtration | Variable; often requires additional drainage layers |

| Environmental Impact | Reduces need for natural fill extraction; synthetic materials usage | High environmental impact due to excavation and material sourcing |

| Durability | Resistant to chemicals, UV, and biological degradation | Susceptible to erosion, weathering, and biological activity |

| Applications | Reinforced slopes, retaining walls, road bases, landfill liners | Structural fills, embankments, backfills |

Introduction to Geosynthetics and Traditional Fill

Geosynthetics are synthetic materials used to reinforce soil, improve drainage, and provide separation between different layers in construction projects, offering enhanced durability and stability compared to traditional fill methods. Traditional fill involves the use of natural soil or aggregate materials placed and compacted on-site, which can be prone to settlement, erosion, and uneven consolidation under load. The engineering performance of geosynthetics often leads to reduced material volumes, quicker installation, and long-term cost savings compared to conventional earthworks relying solely on traditional fill.

Material Composition and Properties

Geosynthetics are engineered materials composed of polymers such as polypropylene, polyethylene, and polyester, designed to provide specific functions like reinforcement, filtration, and drainage in soil structures. Traditional fill typically consists of natural soils or aggregates without uniform properties, leading to variable strength and permeability. The synthetic nature of geosynthetics ensures consistent mechanical strength, durability, and chemical resistance, which often surpasses the performance characteristics of conventional fill materials.

Installation Techniques and Efficiency

Geosynthetics provide advanced installation techniques, including easy unrolling and precise placement, significantly reducing labor time compared to traditional fill methods that rely on heavy machinery and manual compaction. The efficiency of geosynthetics lies in their lightweight, modular design that accelerates site preparation and enhances soil stability, minimizing project delays. Conversely, traditional fill requires extensive material handling and compaction cycles, increasing overall installation time and costs.

Load-Bearing Capacity Comparison

Geosynthetics significantly enhance load-bearing capacity compared to traditional fill by reinforcing soil structure and distributing stress more evenly. Their use reduces settlement and increases stability in foundation and embankment applications, often allowing for thinner layers of fill material. Studies show that geosynthetics can improve bearing capacity by up to 50%, enabling safer and more cost-effective construction on weak soils.

Durability and Longevity

Geosynthetics provide enhanced durability compared to traditional fill materials by resisting degradation from weather, chemicals, and biological factors, ensuring long-term stability in construction projects. Their engineered properties prevent erosion, reduce settlement, and maintain structural integrity, significantly extending the lifespan of infrastructure. Traditional fills often suffer from compaction issues and susceptibility to environmental conditions, leading to frequent maintenance and reduced longevity.

Environmental Impact Assessment

Geosynthetics significantly reduce the environmental impact compared to traditional fill by minimizing the need for natural soil extraction and decreasing landfill waste. Their use enhances soil stabilization and prevents erosion, leading to lower sediment runoff and improved water quality in surrounding ecosystems. Lifecycle assessments demonstrate that geosynthetics contribute to reduced carbon emissions and resource consumption during construction and maintenance phases.

Cost Analysis and Economic Considerations

Geosynthetics significantly reduce overall project costs by minimizing material volume and accelerating construction timelines compared to traditional fill. The initial investment in geosynthetics is offset by lower transportation, labor, and maintenance expenses, offering substantial long-term economic benefits. Cost analysis reveals that using geosynthetics enhances structural performance while delivering a more sustainable and budget-friendly solution for earthworks and retaining structures.

Applications in Civil Engineering Projects

Geosynthetics enhance soil stabilization, drainage, and erosion control in civil engineering projects, outperforming traditional fill materials by providing improved load distribution and reducing settlement. Their applications include reinforced embankments, retaining walls, and road construction, where they extend the lifespan and reduce maintenance costs compared to conventional methods. The use of geosynthetics also accelerates construction timelines while minimizing environmental impact and material usage.

Case Studies and Performance Reviews

Case studies highlight geosynthetics' superior performance compared to traditional fill in erosion control, slope stabilization, and load distribution across infrastructure projects globally. Performance reviews indicate geosynthetics improve soil reinforcement, reduce material costs by up to 30%, and accelerate construction timelines while enhancing durability under varied environmental conditions. Data from transportation and civil engineering applications confirm increased lifespan and reduced maintenance needs when geosynthetics are integrated into earthworks versus conventional fill methods.

Future Trends in Ground Improvement Methods

Geosynthetics are revolutionizing ground improvement by enhancing soil stability, increasing load-bearing capacity, and reducing construction time compared to traditional fill methods. Future trends emphasize the integration of smart geosynthetics embedded with sensors for real-time monitoring and adaptive response to environmental changes. Advances in biodegradable materials and hybrid systems combining geosynthetics with bioengineering techniques are set to optimize sustainability and performance in civil engineering projects.

Reinforced soil structure

Reinforced soil structures using geosynthetics enhance stability and load-bearing capacity compared to traditional fill by providing superior tensile strength, improved soil reinforcement, and reduced settlement.

Tensile strength

Geosynthetics exhibit significantly higher tensile strength than traditional fill materials, enhancing soil stabilization and load-bearing capacity in construction projects.

Filtration efficiency

Geosynthetics provide superior filtration efficiency compared to traditional fill by effectively preventing soil particle migration while maintaining high permeability.

Differential settlement

Geosynthetics reduce differential settlement by enhancing soil reinforcement and load distribution more effectively than traditional fill methods.

Embankment stabilization

Geosynthetics enhance embankment stabilization by improving soil strength, reducing settlement, and providing superior drainage compared to traditional fill materials.

Prefabricated vertical drains

Prefabricated vertical drains in geosynthetics accelerate soil consolidation and improve settlement control more efficiently than traditional fill methods.

Load distribution panel

Geosynthetics enhance load distribution panels by improving soil stability and reducing settlement compared to traditional fill methods.

Separation layer

Geosynthetics as a separation layer effectively prevent intermixing of different soil layers, offering superior durability and performance compared to traditional fill separation methods.

Interface friction angle

Geosynthetics significantly increase the interface friction angle compared to traditional fill materials, enhancing slope stability and reducing soil deformation.

Compaction control

Geosynthetics improve compaction control by reinforcing soil layers and providing uniform density, unlike traditional fill which often suffers from uneven compaction and moisture variation.

Geosynthetics vs Traditional Fill Infographic

njnir.com

njnir.com