Fiber Reinforced Polymers (FRPs) offer superior corrosion resistance compared to traditional steel reinforcement, making them ideal for structures exposed to harsh environmental conditions. FRPs are lightweight, which reduces handling and installation costs while maintaining high tensile strength and durability. However, steel reinforcement remains more cost-effective and has well-established design codes, making it a preferred choice for many conventional civil engineering applications.

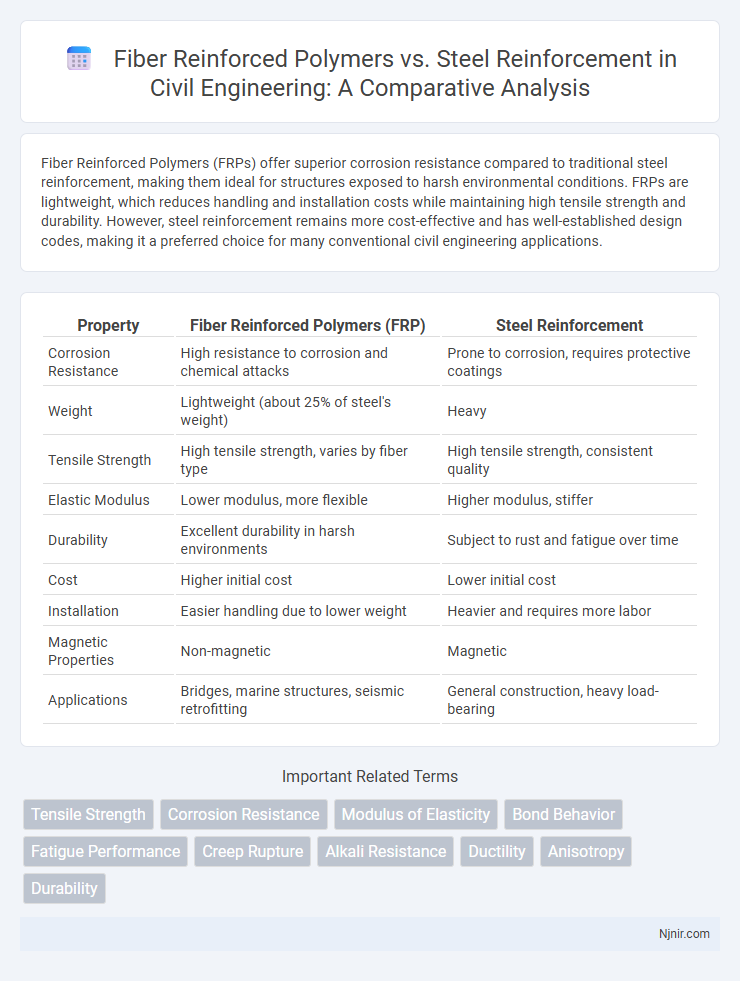

Table of Comparison

| Property | Fiber Reinforced Polymers (FRP) | Steel Reinforcement |

|---|---|---|

| Corrosion Resistance | High resistance to corrosion and chemical attacks | Prone to corrosion, requires protective coatings |

| Weight | Lightweight (about 25% of steel's weight) | Heavy |

| Tensile Strength | High tensile strength, varies by fiber type | High tensile strength, consistent quality |

| Elastic Modulus | Lower modulus, more flexible | Higher modulus, stiffer |

| Durability | Excellent durability in harsh environments | Subject to rust and fatigue over time |

| Cost | Higher initial cost | Lower initial cost |

| Installation | Easier handling due to lower weight | Heavier and requires more labor |

| Magnetic Properties | Non-magnetic | Magnetic |

| Applications | Bridges, marine structures, seismic retrofitting | General construction, heavy load-bearing |

Introduction to Fiber Reinforced Polymers and Steel Reinforcement

Fiber Reinforced Polymers (FRPs) are composite materials consisting of polymer matrices reinforced with fibers like glass, carbon, or aramid, offering high strength-to-weight ratios and corrosion resistance. Steel reinforcement, traditionally used in concrete structures, provides excellent tensile strength and ductility but is prone to corrosion and requires protective coatings. The choice between FRPs and steel reinforcement depends on factors such as durability, environmental exposure, mechanical performance, and project lifecycle costs.

Material Properties: FRP vs Steel

Fiber Reinforced Polymers (FRP) exhibit high strength-to-weight ratios, corrosion resistance, and low thermal conductivity, making them advantageous over traditional steel reinforcement in harsh environments. Steel reinforcement, while strong and ductile with predictable yield behavior, is prone to corrosion and has a higher density, which can increase structural weight. FRP materials also demonstrate non-magnetic properties and superior fatigue resistance, contributing to longer service life in infrastructure applications.

Durability and Corrosion Resistance

Fiber Reinforced Polymers (FRPs) exhibit superior durability and corrosion resistance compared to traditional steel reinforcement, as FRPs are non-metallic and inert to moisture, chlorides, and chemical attacks. Unlike steel, which corrodes over time in the presence of water and salts, leading to structural weakening and maintenance costs, FRP maintains long-term structural integrity without rust formation. This corrosion resistance makes FRP ideal for harsh environments such as marine, industrial, and bridge infrastructure applications where longevity and reduced maintenance are critical.

Mechanical Strength and Structural Performance

Fiber Reinforced Polymers (FRPs) offer higher tensile strength-to-weight ratios compared to traditional steel reinforcement, enhancing load-carrying capacity and corrosion resistance in structural applications. Unlike steel, FRPs exhibit superior fatigue resistance and maintain mechanical strength in harsh environmental conditions, extending service life and reducing maintenance costs. Structural performance is improved through FRPs' non-magnetic and non-corrosive properties, which prevent deterioration and ensure consistent reinforcement effectiveness over time.

Weight and Ease of Handling

Fiber Reinforced Polymers (FRPs) offer significant weight advantages over traditional steel reinforcement, typically weighing about 70-80% less, which reduces the overall structural load and simplifies transportation. The lightweight nature of FRPs enhances ease of handling on construction sites, allowing for faster installation and reduced labor costs compared to steel's heavier and more cumbersome components. Moreover, FRPs are corrosion-resistant, eliminating the need for additional protective coatings and further streamlining construction processes.

Installation Techniques and Construction Methods

Fiber Reinforced Polymers (FRP) offer lightweight and corrosion-resistant properties that simplify installation techniques compared to traditional steel reinforcement, reducing labor costs and time on construction sites. FRP reinforcement can be prefabricated and easily shaped, allowing for faster placement using manual or mechanized methods without heavy equipment. Steel reinforcement requires more extensive handling due to its weight and susceptibility to corrosion, necessitating protective coatings and specialized welding or tying techniques during construction.

Lifecycle Cost Analysis

Fiber Reinforced Polymers (FRPs) exhibit lower lifecycle costs compared to steel reinforcement due to their superior corrosion resistance and reduced maintenance requirements, enhancing durability in concrete structures. The initial investment in FRPs is often higher, but long-term savings emerge from decreased repair frequency and extended service life, particularly in aggressive environments. Lifecycle cost analysis consistently shows that FRP reinforcement offers a cost-effective alternative by minimizing structural deterioration, rehabilitation efforts, and associated downtime.

Environmental Impact and Sustainability

Fiber Reinforced Polymers (FRPs) offer significant environmental advantages over steel reinforcement due to their lower carbon footprint and resistance to corrosion, which reduces the need for frequent repairs and replacements. The production of FRPs consumes less energy and generates fewer greenhouse gas emissions compared to steel manufacturing. Sustainable construction benefits from FRPs' lightweight properties and longer lifespan, contributing to reduced resource consumption and enhanced durability in infrastructure projects.

Applications in Modern Civil Engineering

Fiber Reinforced Polymers (FRPs) offer superior corrosion resistance, lightweight properties, and high tensile strength, making them ideal for bridge decks, marine structures, and retrofitting applications in modern civil engineering. Steel reinforcement remains preferred for its ductility, cost-effectiveness, and well-established performance in high-load structural elements such as beams, columns, and foundations. The integration of FRPs with steel reinforcements addresses durability challenges while enhancing the longevity and seismic resilience of infrastructure projects.

Future Trends and Innovations in Reinforcement Material

Fiber Reinforced Polymers (FRPs) are increasingly favored over traditional steel reinforcement due to their superior corrosion resistance, lightweight properties, and high tensile strength, making them ideal for infrastructure longevity and reduced maintenance costs. Innovations in smart FRPs embedded with sensors enable real-time structural health monitoring, enhancing safety and predictive maintenance capabilities. Ongoing research focuses on hybrid reinforcement systems combining FRPs and steel to optimize load-bearing efficiency while addressing cost and environmental sustainability challenges.

Tensile Strength

Fiber reinforced polymers exhibit tensile strengths up to three times higher than traditional steel reinforcement, offering superior durability and corrosion resistance in structural applications.

Corrosion Resistance

Fiber Reinforced Polymers exhibit superior corrosion resistance compared to Steel Reinforcement, significantly enhancing durability and reducing maintenance costs in construction applications.

Modulus of Elasticity

Fiber reinforced polymers have a modulus of elasticity typically ranging from 30 to 50 GPa, which is lower than steel reinforcement's modulus of elasticity of approximately 200 GPa, making FRP less stiff but advantageous for corrosion resistance in structural applications.

Bond Behavior

Fiber reinforced polymers exhibit superior corrosion resistance and reduced bonding degradation compared to steel reinforcement, enhancing long-term bond behavior in concrete structures.

Fatigue Performance

Fiber reinforced polymers exhibit superior fatigue performance compared to steel reinforcement, offering enhanced durability and resistance to cyclic loading in structural applications.

Creep Rupture

Fiber reinforced polymers exhibit significantly higher creep rupture resistance compared to traditional steel reinforcement, making them ideal for long-term structural applications under sustained loads.

Alkali Resistance

Fiber Reinforced Polymers exhibit superior alkali resistance compared to steel reinforcement, ensuring enhanced durability and reduced corrosion in concrete structures.

Ductility

Fiber Reinforced Polymers exhibit lower ductility compared to steel reinforcement, making steel preferable in applications requiring significant deformation before failure.

Anisotropy

Fiber reinforced polymers exhibit pronounced anisotropy with direction-dependent strength and stiffness, whereas steel reinforcement offers more isotropic mechanical properties with uniform behavior across orientations.

Durability

Fiber Reinforced Polymers (FRPs) offer superior corrosion resistance and longer service life compared to steel reinforcement, making them more durable in harsh environmental conditions.

Fiber Reinforced Polymers vs Steel Reinforcement Infographic

njnir.com

njnir.com