Steel fiber reinforcement offers superior tensile strength and ductility compared to glass fiber, making it ideal for high-load structural applications in civil engineering. Glass fiber reinforcement excels in corrosion resistance and lightweight properties, suitable for environments exposed to moisture and chemicals. Selecting between steel and glass fibers depends on project-specific requirements such as load-bearing capacity, durability, and environmental conditions.

Table of Comparison

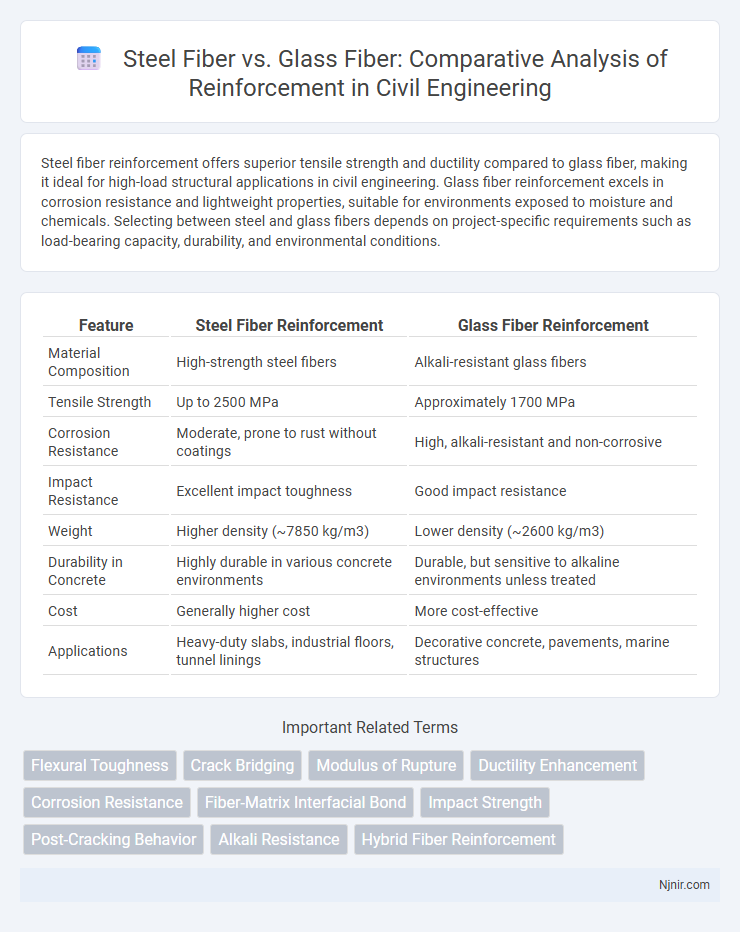

| Feature | Steel Fiber Reinforcement | Glass Fiber Reinforcement |

|---|---|---|

| Material Composition | High-strength steel fibers | Alkali-resistant glass fibers |

| Tensile Strength | Up to 2500 MPa | Approximately 1700 MPa |

| Corrosion Resistance | Moderate, prone to rust without coatings | High, alkali-resistant and non-corrosive |

| Impact Resistance | Excellent impact toughness | Good impact resistance |

| Weight | Higher density (~7850 kg/m3) | Lower density (~2600 kg/m3) |

| Durability in Concrete | Highly durable in various concrete environments | Durable, but sensitive to alkaline environments unless treated |

| Cost | Generally higher cost | More cost-effective |

| Applications | Heavy-duty slabs, industrial floors, tunnel linings | Decorative concrete, pavements, marine structures |

Introduction to Fiber Reinforcement in Civil Engineering

Fiber reinforcement in civil engineering enhances concrete's tensile strength, durability, and crack resistance by integrating materials like steel fibers and glass fibers. Steel fibers, known for their high tensile strength and ductility, improve structural load capacity and impact resistance, making them suitable for heavy-duty applications. Glass fibers offer corrosion resistance and lightweight properties, ideal for environments requiring non-metallic reinforcement and thermal insulation.

Composition and Properties of Steel Fibers

Steel fibers are composed primarily of low-carbon steel, offering high tensile strength and excellent ductility. These fibers exhibit superior impact resistance, improved load-bearing capacity, and enhanced crack control compared to glass fibers. Their metallic composition provides better bonding with concrete matrices, contributing to increased structural toughness and durability in reinforced applications.

Characteristics of Glass Fiber Reinforcement

Glass fiber reinforcement offers high tensile strength and excellent corrosion resistance, making it ideal for applications exposed to moisture and chemicals. Its lightweight nature combined with good thermal stability enhances structural performance without adding significant weight. The non-conductive properties of glass fiber also provide electrical insulation benefits in composite materials.

Mechanical Performance: Steel vs. Glass Fiber

Steel fibers exhibit superior tensile strength and impact resistance compared to glass fibers, making them highly effective in enhancing the flexural toughness and crack control of concrete. Glass fibers, while offering better corrosion resistance and lighter weight, typically provide lower modulus of elasticity and reduced load-bearing capacity under dynamic stresses. Mechanical performance evaluation in structural applications often favors steel fiber reinforcement for high-strength concrete due to its enhanced energy absorption and post-crack load-carrying capacity.

Durability and Corrosion Resistance Comparison

Steel fiber reinforcement offers superior tensile strength and durability in high-stress environments but is susceptible to corrosion, especially in chloride-rich conditions. Glass fiber reinforcement provides excellent corrosion resistance and maintains long-term durability in chemically aggressive environments due to its non-metallic nature. Selecting between steel and glass fibers depends on the specific exposure risks, with glass fibers preferred for corrosion-prone applications and steel fibers favored where mechanical load capacity is critical.

Cost Analysis: Steel Fiber versus Glass Fiber

Steel fiber reinforcement typically incurs higher upfront material costs compared to glass fiber due to its superior tensile strength and durability. Glass fiber offers a more cost-effective option for projects with budget constraints, as it provides adequate reinforcement at a lower price point. Long-term maintenance and lifecycle expenses often favor steel fiber, given its enhanced resistance to corrosion and impact.

Workability and Construction Techniques

Steel fiber reinforcement enhances workability by improving concrete's resistance to cracking and providing superior load distribution, making it ideal for structures requiring high tensile strength and durability. Glass fiber reinforcement offers easier mixing and finishing due to its lightweight and corrosion resistance, which benefits applications where aesthetics and chemical stability are crucial. Construction techniques involving steel fibers demand careful handling to ensure even dispersion, while glass fibers allow for faster application but require attention to avoid fiber balling during mixing.

Application Areas in Civil Engineering Projects

Steel fiber reinforcement excels in applications requiring high tensile strength and crack resistance, such as industrial floors, bridge decks, and tunnel linings, where durability under heavy loads is critical. Glass fiber reinforcement is favored in non-structural elements like wall panels, facades, and architectural cladding due to its lightweight properties and corrosion resistance. Both materials enhance concrete performance, but steel fibers are ideal for structural strengthening, while glass fibers are suited for aesthetic and lightweight civil engineering components.

Environmental Impact and Sustainability

Steel fiber reinforcement offers high durability and recyclability, contributing to a lower environmental footprint due to its long lifecycle and potential for reuse in construction applications. Glass fiber reinforcement, while providing corrosion resistance and lightweight properties, involves higher energy consumption during production and challenges in recycling that can affect sustainability goals. Selecting steel fibers over glass fibers can enhance eco-friendly construction by reducing waste and promoting circular economy practices in infrastructure development.

Future Trends in Fiber Reinforcement Technologies

Future trends in fiber reinforcement technologies emphasize the development of hybrid composites combining steel fiber and glass fiber to maximize tensile strength and durability in construction materials. Innovations in nanotechnology and surface treatments are enhancing fiber-matrix bonding, leading to improved mechanical properties and corrosion resistance. Sustainable and eco-friendly fiber alternatives are gaining momentum, focusing on reducing carbon footprints while maintaining high performance in fiber-reinforced concrete and polymer composites.

Flexural Toughness

Steel fiber reinforcement provides higher flexural toughness than glass fiber reinforcement due to its superior crack-bridging ability and tensile strength.

Crack Bridging

Steel fibers provide superior crack bridging performance compared to glass fibers due to their higher tensile strength and ductility, enhancing concrete durability and load-bearing capacity.

Modulus of Rupture

Steel fiber reinforcement significantly enhances the Modulus of Rupture in concrete by providing superior tensile strength and crack resistance compared to glass fiber reinforcement.

Ductility Enhancement

Steel fiber reinforcement significantly enhances ductility in concrete structures by providing superior tensile strength and crack resistance compared to glass fiber reinforcement.

Corrosion Resistance

Steel fiber reinforcement offers superior mechanical strength while glass fiber reinforcement provides enhanced corrosion resistance in harsh environmental conditions.

Fiber-Matrix Interfacial Bond

Steel fiber reinforcement exhibits superior fiber-matrix interfacial bond strength compared to glass fiber reinforcement due to its higher mechanical anchorage and corrosion resistance, resulting in enhanced composite durability and load transfer efficiency.

Impact Strength

Steel fiber reinforcement exhibits significantly higher impact strength compared to glass fiber reinforcement, making it more suitable for applications requiring superior durability against sudden forces.

Post-Cracking Behavior

Steel fiber reinforcement exhibits superior post-cracking toughness and crack-bridging capacity compared to glass fiber reinforcement, resulting in enhanced ductility and durability in concrete structures.

Alkali Resistance

Steel fibers offer superior tensile strength but lack alkali resistance, whereas glass fibers provide excellent alkali resistance ideal for corrosive environments in concrete reinforcement.

Hybrid Fiber Reinforcement

Hybrid fiber reinforcement combines steel fibers' high tensile strength and glass fibers' corrosion resistance to enhance concrete's durability, toughness, and crack control performance.

Steel Fiber vs Glass Fiber Reinforcement Infographic

njnir.com

njnir.com