The water-cement ratio significantly influences the strength and durability of concrete, with lower ratios yielding higher strength but reduced workability. The aggregate-cement ratio affects the concrete's density and volume stability, where an optimal balance ensures proper compaction and minimal voids. Both ratios must be carefully controlled to achieve desired mechanical properties and longevity in civil engineering structures.

Table of Comparison

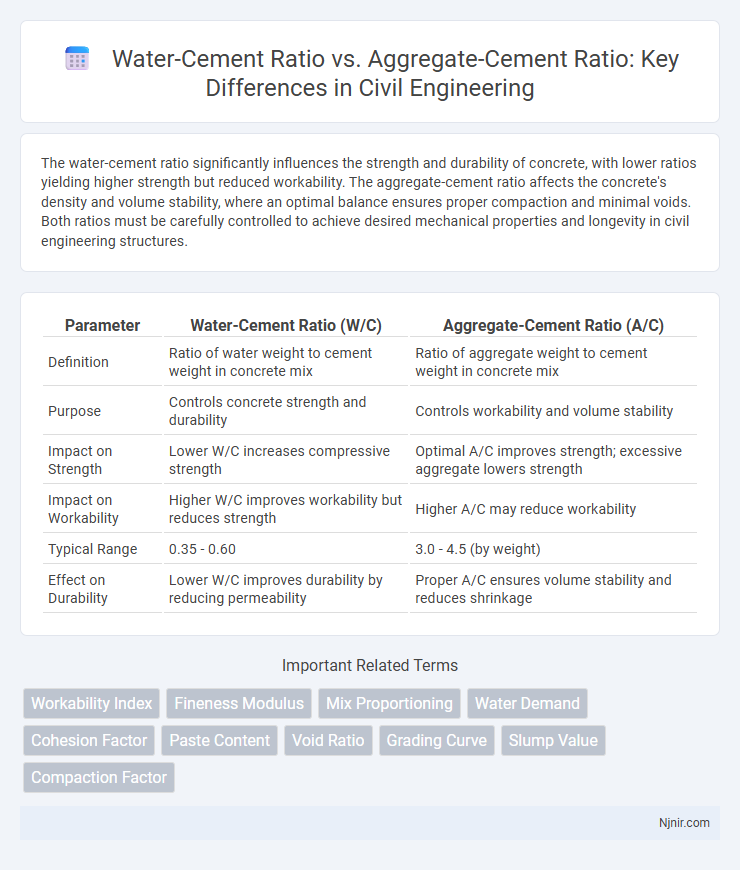

| Parameter | Water-Cement Ratio (W/C) | Aggregate-Cement Ratio (A/C) |

|---|---|---|

| Definition | Ratio of water weight to cement weight in concrete mix | Ratio of aggregate weight to cement weight in concrete mix |

| Purpose | Controls concrete strength and durability | Controls workability and volume stability |

| Impact on Strength | Lower W/C increases compressive strength | Optimal A/C improves strength; excessive aggregate lowers strength |

| Impact on Workability | Higher W/C improves workability but reduces strength | Higher A/C may reduce workability |

| Typical Range | 0.35 - 0.60 | 3.0 - 4.5 (by weight) |

| Effect on Durability | Lower W/C improves durability by reducing permeability | Proper A/C ensures volume stability and reduces shrinkage |

Introduction to Water-Cement and Aggregate-Cement Ratios

Water-cement ratio refers to the proportion of water to cement by weight in a concrete mix, critically influencing strength, durability, and workability. Aggregate-cement ratio measures the quantity of aggregate relative to cement, impacting the mix's density and structural performance. Both ratios must be carefully optimized to achieve desired concrete properties and ensure optimal hydration and bonding.

Importance of Mix Proportions in Concrete Design

Precise water cement ratio and aggregate cement ratio are critical for achieving desired concrete strength, durability, and workability, making accurate mix proportions essential in concrete design. A low water cement ratio improves compressive strength but requires careful adjustment of the aggregate cement ratio to maintain proper workability and avoid segregation. Optimizing these ratios ensures a balanced concrete mix that enhances structural performance and reduces the risk of cracking and shrinkage.

Defining Water-Cement Ratio: Concept and Significance

The water-cement ratio defines the weight of water relative to the weight of cement in a concrete mix, playing a crucial role in determining the concrete's strength and durability. Maintaining an optimal water-cement ratio ensures proper hydration of cement particles and minimizes porosity, directly affecting compressive strength and permeability. This ratio contrasts with the aggregate-cement ratio, which controls workability and volume stability by balancing the proportions of aggregates against cement content.

Aggregate-Cement Ratio: Role in Concrete Composition

The aggregate-cement ratio plays a crucial role in determining the strength, durability, and workability of concrete by balancing coarse and fine aggregates with cement content. A higher aggregate-cement ratio generally reduces the cement paste volume, affecting the concrete's bonding properties and leading to lower strength but improved economy and dimensional stability. Optimizing the aggregate-cement ratio is essential for achieving desired concrete performance, including resistance to cracking, shrinkage, and environmental degradation.

Impact of Water-Cement Ratio on Concrete Strength

The water-cement ratio critically influences concrete strength by controlling the hydration process and porosity within the hardened matrix, where lower ratios typically increase compressive strength and durability. Conversely, aggregate-cement ratio affects the concrete's volume stability and density but does not directly determine the binding strength as significantly as the water-cement ratio. Precise management of water-cement ratio optimizes concrete performance to meet structural requirements without compromising workability and resistance to environmental factors.

Influence of Aggregate-Cement Ratio on Workability

The aggregate-cement ratio significantly influences the workability of concrete by affecting its consistency and ease of placement. Higher aggregate-cement ratios typically decrease workability due to increased particle interlock and reduced cement paste to lubricate the mix. Optimizing this ratio ensures adequate paste to cover aggregates, improving flowability and compactness while maintaining structural integrity.

Comparative Analysis: Water-Cement Ratio vs Aggregate-Cement Ratio

The water-cement ratio critically influences concrete strength and durability by controlling hydration and porosity, with lower ratios yielding higher compressive strength. The aggregate-cement ratio primarily affects workability and volume stability, where higher aggregate content reduces shrinkage but may compromise cohesiveness. Balancing optimal water-cement and aggregate-cement ratios is essential for achieving desired mechanical properties and long-term performance in concrete mixes.

Optimizing Concrete Mix: Balancing Both Ratios

Optimizing concrete mix requires balancing the water cement ratio and aggregate cement ratio to achieve desired strength and durability. A lower water cement ratio improves compressive strength but may reduce workability, while the aggregate cement ratio influences the concrete's density and stability. Precise adjustments of both ratios ensure optimal hydration and aggregate packing, enhancing overall concrete performance and lifespan.

Practical Considerations and Industry Standards

Water cement ratio critically impacts concrete strength and durability, with industry standards like ACI 318 recommending ratios typically between 0.4 and 0.6 for structural applications to ensure optimal hydration and minimal porosity. Aggregate cement ratio influences workability and volume stability, often maintained between 4:1 and 6:1 in practice to balance strength and economy. Practical considerations include controlling moisture content in aggregates and adjusting mix proportions based on specific project requirements to meet standardized performance criteria.

Conclusion: Choosing the Right Ratios for Durable Concrete

Selecting the optimal water cement ratio ensures adequate hydration and strength development while minimizing porosity and cracking. The aggregate cement ratio influences the concrete's density, workability, and load-bearing capacity by balancing fine and coarse materials. Achieving durable concrete requires a precise combination of both ratios tailored to the specific structural requirements and environmental conditions.

Workability Index

The workability index improves as the water-cement ratio increases while higher aggregate-cement ratios typically reduce workability by decreasing the mix's cohesiveness.

Fineness Modulus

The fineness modulus significantly influences the aggregate-cement ratio by affecting aggregate grading, which in turn impacts the water-cement ratio required for optimal concrete workability and strength.

Mix Proportioning

Optimizing mix proportioning requires balancing water-cement ratio to control hydration and strength, while adjusting aggregate-cement ratio to enhance workability and volume stability in concrete.

Water Demand

The water demand in concrete increases significantly with a higher water-cement ratio but is less sensitive to changes in the aggregate-cement ratio, impacting strength and workability.

Cohesion Factor

The water-cement ratio primarily influences the cohesion factor by controlling the workability and bonding strength, while the aggregate-cement ratio affects cohesion by determining the mixture's particle packing and internal friction.

Paste Content

Water-cement ratio primarily influences the paste content affecting workability and strength, while the aggregate-cement ratio determines the volume of paste needed to coat aggregates and control the concrete's overall durability and density.

Void Ratio

The void ratio in concrete is significantly influenced by the water-cement ratio, which controls hydration and porosity, while the aggregate-cement ratio affects particle packing density and thus the volume of voids within the hardened mix.

Grading Curve

The grading curve significantly influences the water-cement ratio and aggregate-cement ratio by determining particle size distribution, which affects workability, strength, and durability of concrete.

Slump Value

A lower water cement ratio increases slump value by enhancing workability, while a higher aggregate cement ratio decreases slump value due to reduced paste volume and cohesiveness.

Compaction Factor

Higher water-cement ratios typically decrease the compaction factor due to increased workability but reduced density, while aggregate-cement ratios influence compaction factor by altering the mix's particle packing and void reduction.

Water Cement Ratio vs Aggregate Cement Ratio Infographic

njnir.com

njnir.com