Smart sensors provide continuous, real-time monitoring of structural health, enabling early detection of potential failures and reducing the risk of human error inherent in manual inspections. These advanced devices improve data accuracy and enable predictive maintenance by collecting and analyzing vast amounts of information on stress, strain, and environmental conditions. Manual inspection remains essential for complex visual assessments, but integrating smart sensors significantly enhances overall safety and efficiency in civil engineering projects.

Table of Comparison

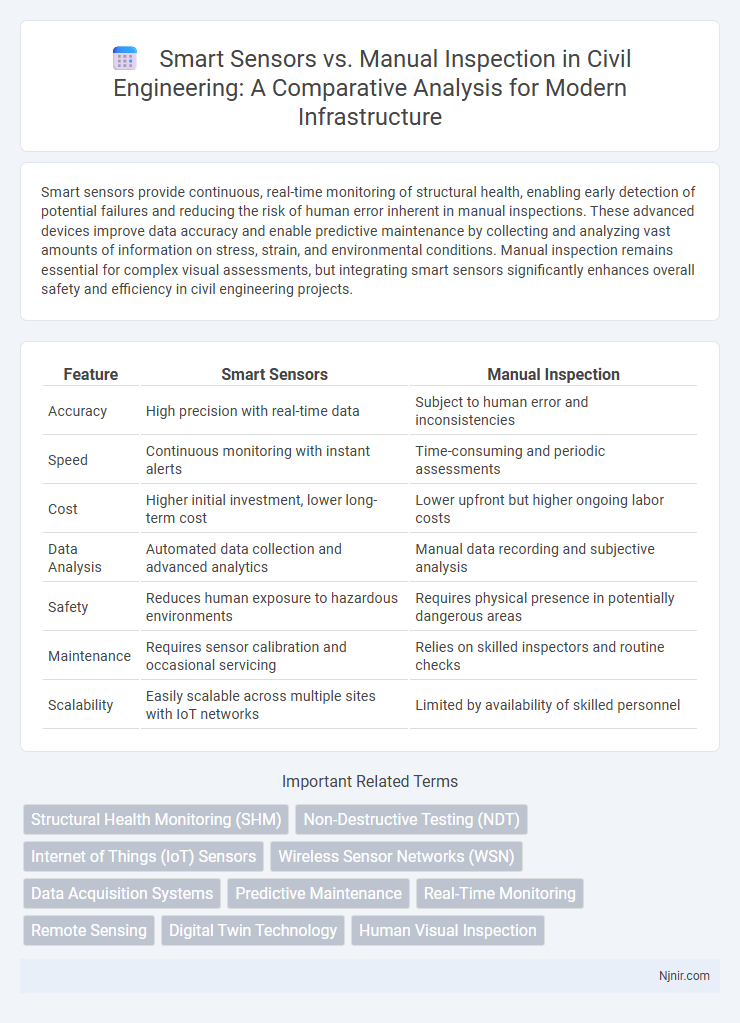

| Feature | Smart Sensors | Manual Inspection |

|---|---|---|

| Accuracy | High precision with real-time data | Subject to human error and inconsistencies |

| Speed | Continuous monitoring with instant alerts | Time-consuming and periodic assessments |

| Cost | Higher initial investment, lower long-term cost | Lower upfront but higher ongoing labor costs |

| Data Analysis | Automated data collection and advanced analytics | Manual data recording and subjective analysis |

| Safety | Reduces human exposure to hazardous environments | Requires physical presence in potentially dangerous areas |

| Maintenance | Requires sensor calibration and occasional servicing | Relies on skilled inspectors and routine checks |

| Scalability | Easily scalable across multiple sites with IoT networks | Limited by availability of skilled personnel |

Introduction to Smart Sensors and Manual Inspection

Smart sensors integrate advanced technologies such as IoT connectivity and machine learning algorithms to provide real-time data and automated analysis in various industries. Manual inspection relies on human expertise and visual or tactile examination to identify defects, irregularities, or quality issues without the aid of automated systems. The contrast between automated precision of smart sensors and the subjective nature of manual inspection highlights a significant shift toward enhanced accuracy and efficiency in monitoring and quality control processes.

Evolution of Monitoring Methods in Civil Engineering

Smart sensors have revolutionized monitoring methods in civil engineering by enabling real-time data collection, precise measurements, and automated reporting, significantly outperforming manual inspection's reliance on periodic, subjective assessments. Integration of IoT technologies and machine learning algorithms in smart sensor systems enhances predictive maintenance and structural health monitoring, reducing human error and improving safety. The evolution from manual to smart sensor-based monitoring reflects a shift towards proactive infrastructure management, optimizing resource allocation and extending the lifespan of civil structures.

Key Differences: Smart Sensors vs Manual Inspection

Smart sensors provide real-time, precise data by continuously monitoring environmental or operational conditions, enabling automated detection and analysis unlike manual inspection, which relies on periodic visual checks prone to human error. These sensors can detect subtle changes through advanced technologies like infrared, ultrasonic, or vibration analysis, offering higher accuracy and faster response compared to the slower, labor-intensive manual process. The integration of smart sensors reduces downtime and maintenance costs by predicting failures early, whereas manual inspection often results in delayed fault identification and inconsistent quality control.

Accuracy and Reliability of Data Collection

Smart sensors provide highly accurate and real-time data collection by continuously monitoring environmental and operational parameters, minimizing human error compared to manual inspection. These sensors enhance reliability through automated, consistent measurements unaffected by operator fatigue or subjective judgment. Manual inspections can introduce variability and delays in detecting anomalies, whereas smart sensors enable proactive maintenance and improved decision-making based on precise, uninterrupted data streams.

Real-Time Monitoring Capabilities

Smart sensors enable continuous real-time monitoring by providing instant data on environmental changes, equipment status, and performance metrics, significantly improving accuracy compared to manual inspections. Manual inspection relies on periodic checks, which can miss transient issues and lead to delayed responses and increased downtime. The integration of smart sensors with IoT platforms facilitates automated alerts, predictive maintenance, and data analytics, enhancing operational efficiency and reducing human error.

Cost and Resource Efficiency Analysis

Smart sensors significantly reduce operational costs by enabling real-time data collection and automated monitoring, minimizing the need for manual labor and lowering human error rates. Manual inspection requires substantial human resources and incurs higher long-term expenses due to labor costs, slower inspection times, and potential for missed defects. Investing in smart sensor technology enhances resource efficiency by streamlining maintenance processes and providing predictive analytics, which further reduces downtime and associated costs.

Safety Considerations in Structural Assessment

Smart sensors provide continuous real-time monitoring of structural integrity, significantly reducing the risk of human error and exposure to hazardous environments during inspections. Manual inspection often requires physical access to potentially unstable structures, increasing safety risks for inspectors due to falls, debris, or structural failure. Implementing smart sensor technology enhances safety by allowing remote assessment and early detection of structural issues, thereby preventing catastrophic failures and protecting both personnel and assets.

Integration of Smart Sensors in Existing Infrastructure

Integrating smart sensors into existing infrastructure enhances real-time data collection and predictive maintenance capabilities, significantly reducing operational downtime compared to manual inspection methods. Smart sensors offer continuous monitoring through IoT connectivity, enabling seamless data transmission and analytics integration within current systems. This upgrade fosters improved accuracy, faster response times, and cost efficiency in industrial and manufacturing environments.

Limitations and Challenges of Each Approach

Smart sensors struggle with accuracy in complex environments and often require high initial investment, making them less accessible for small-scale operations. Manual inspection faces challenges such as human error, inconsistency, and labor-intensive processes, which can lead to slower detection and increased operational costs. Both approaches encounter limitations in scalability and adaptability, emphasizing the need for integrated solutions to optimize performance and reliability.

Future Trends in Structural Health Monitoring

Smart sensors are revolutionizing structural health monitoring by enabling real-time data collection and predictive maintenance, reducing human error inherent in manual inspections. Future trends emphasize the integration of AI-driven analytics with IoT-enabled smart sensors, facilitating continuous monitoring and early detection of structural anomalies. Enhanced sensor miniaturization and wireless communication technologies are set to improve accessibility and accuracy in monitoring critical infrastructure over traditional manual inspection methods.

Structural Health Monitoring (SHM)

Smart sensors enhance Structural Health Monitoring (SHM) by providing continuous, real-time data for accurate damage detection and predictive maintenance, outperforming intermittent and subjective manual inspection methods.

Non-Destructive Testing (NDT)

Smart sensors enhance Non-Destructive Testing (NDT) by providing real-time, precise data analysis, improving accuracy and efficiency compared to traditional manual inspection methods.

Internet of Things (IoT) Sensors

IoT smart sensors enhance accuracy and efficiency by providing real-time data and automated monitoring compared to manual inspection methods.

Wireless Sensor Networks (WSN)

Wireless Sensor Networks (WSN) enhance smart sensors' efficiency by providing real-time, remote monitoring and data accuracy, significantly outperforming manual inspection in speed, reliability, and scalability.

Data Acquisition Systems

Smart sensors integrated into advanced data acquisition systems provide real-time, precise measurements and automated monitoring, significantly outperforming manual inspection in accuracy, efficiency, and data consistency.

Predictive Maintenance

Smart sensors enhance predictive maintenance by continuously monitoring equipment conditions in real-time, enabling early fault detection and reducing downtime compared to periodic manual inspections.

Real-Time Monitoring

Smart sensors enable continuous real-time monitoring with higher accuracy and faster detection of anomalies compared to intermittent manual inspection methods.

Remote Sensing

Remote sensing in smart sensors enables real-time, precise data collection from inaccessible locations, surpassing the limitations and labor intensity of manual inspection processes.

Digital Twin Technology

Smart sensors integrated with digital twin technology provide real-time, precise data analytics and predictive maintenance capabilities, outperforming manual inspection by enhancing operational efficiency and reducing downtime.

Human Visual Inspection

Human visual inspection relies on expert observation and subjective analysis, often leading to variability and slower detection compared to the consistent, real-time accuracy of smart sensors.

Smart Sensors vs Manual Inspection Infographic

njnir.com

njnir.com