Steel fiber reinforcement provides superior tensile strength and crack resistance for concrete structures compared to glass fiber, enhancing durability under heavy loads. Glass fiber offers excellent corrosion resistance and lighter weight, making it ideal for non-structural or lightweight applications where chemical stability is crucial. Selecting between steel fiber and glass fiber depends on specific project requirements, balancing strength, durability, and environmental factors.

Table of Comparison

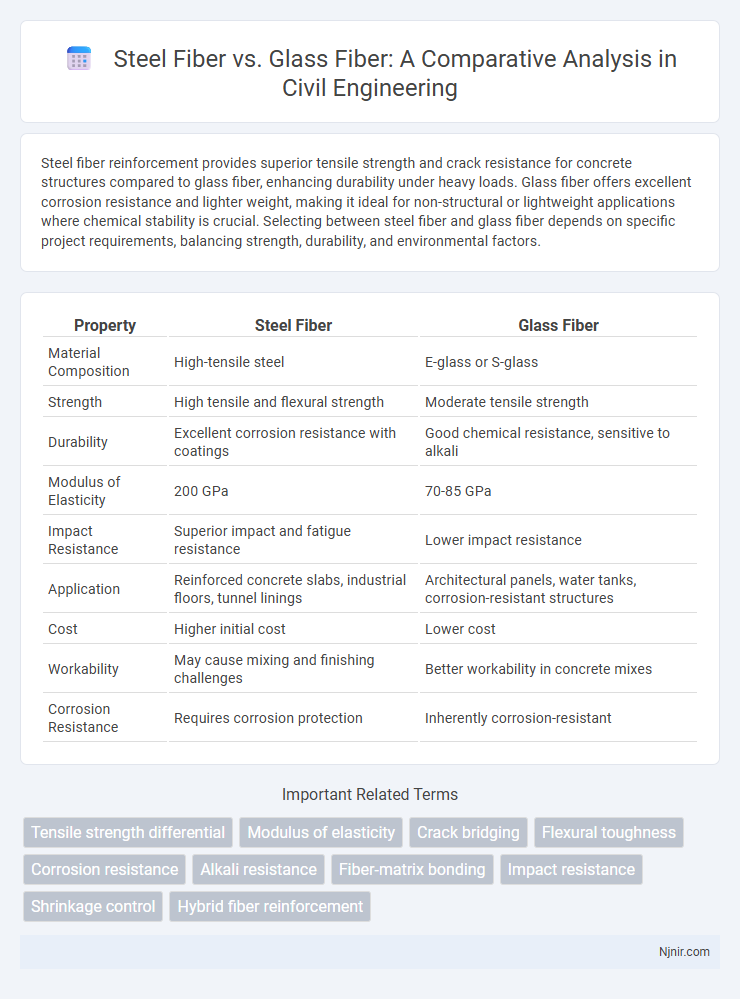

| Property | Steel Fiber | Glass Fiber |

|---|---|---|

| Material Composition | High-tensile steel | E-glass or S-glass |

| Strength | High tensile and flexural strength | Moderate tensile strength |

| Durability | Excellent corrosion resistance with coatings | Good chemical resistance, sensitive to alkali |

| Modulus of Elasticity | 200 GPa | 70-85 GPa |

| Impact Resistance | Superior impact and fatigue resistance | Lower impact resistance |

| Application | Reinforced concrete slabs, industrial floors, tunnel linings | Architectural panels, water tanks, corrosion-resistant structures |

| Cost | Higher initial cost | Lower cost |

| Workability | May cause mixing and finishing challenges | Better workability in concrete mixes |

| Corrosion Resistance | Requires corrosion protection | Inherently corrosion-resistant |

Introduction to Steel Fiber and Glass Fiber in Civil Engineering

Steel fiber and glass fiber are commonly used reinforcement materials in civil engineering to enhance concrete performance. Steel fibers provide superior tensile strength, impact resistance, and durability, making them ideal for heavy-duty applications such as industrial floors and precast concrete elements. Glass fibers offer corrosion resistance and improved flexibility, often utilized in architectural panels and lightweight concrete where reducing weight without sacrificing strength is critical.

Material Properties Comparison: Steel Fiber vs Glass Fiber

Steel fibers exhibit higher tensile strength, superior toughness, and enhanced impact resistance compared to glass fibers, making them ideal for reinforcing concrete structures subjected to heavy loads. Glass fibers offer excellent corrosion resistance, lightweight properties, and good thermal insulation, which make them preferable in environments where chemical exposure and weight reduction are crucial. The choice between steel and glass fibers depends on performance requirements such as durability, mechanical strength, and environmental conditions influencing material longevity.

Manufacturing Process Differences

Steel fiber manufacturing involves the cold drawing or cutting of steel wire into specific lengths, followed by surface treatment to enhance bonding with concrete, resulting in high tensile strength fibers. Glass fibers are produced through the melting of raw materials like silica sand, borax, and limestone at temperatures around 1700degC, then extruded into fine filaments and coated with sizing agents to improve adhesion within composite materials. The steel fiber process emphasizes mechanical cutting and metal treatment, whereas glass fiber manufacturing relies on thermal melting and extrusion techniques, leading to distinct material properties and applications.

Mechanical Performance Under Load

Steel fiber reinforcement offers superior tensile strength and crack resistance under high load conditions compared to glass fiber, making it ideal for heavy-duty structural applications. Glass fiber provides excellent flexibility and corrosion resistance, but tends to exhibit lower impact toughness and modulus of elasticity under sustained mechanical stress. The choice between steel and glass fiber depends on the specific load-bearing requirements and environmental factors affecting the composite material's performance.

Durability and Corrosion Resistance

Steel fiber offers exceptional durability and superior mechanical strength, making it ideal for heavy-duty construction applications, but it is prone to corrosion if not properly coated or maintained. Glass fiber provides excellent corrosion resistance due to its inert chemical composition, ensuring long-lasting performance in harsh environments, though it may have lower tensile strength compared to steel fiber. Choosing between steel fiber and glass fiber depends on balancing the need for structural durability with exposure to corrosive conditions.

Applications in Concrete Reinforcement

Steel fiber reinforcement in concrete is commonly used in heavy-duty applications such as industrial floors, bridge decks, and tunneling due to its high tensile strength and durability. Glass fiber reinforced concrete (GFRC) is preferred for architectural panels, facade elements, and decorative features because of its lightweight properties and corrosion resistance. Both fibers enhance crack control and structural integrity, but steel fibers excel in impact resistance while glass fibers offer superior flexibility and finish quality.

Cost Analysis and Economic Considerations

Steel fiber reinforcement generally incurs a higher initial cost compared to glass fiber due to its raw material and manufacturing expenses. However, steel fibers offer superior durability and tensile strength, which can reduce long-term maintenance and replacement costs in infrastructure projects. Glass fiber serves as a cost-effective alternative with lower upfront expenses but may lead to higher lifecycle costs due to susceptibility to corrosion and reduced mechanical performance under certain conditions.

Installation Techniques and Practicality

Steel fiber reinforcement requires heavier machinery and specialized equipment for mixing and pouring due to its density and rigidity, resulting in a longer installation time and higher labor costs. Glass fiber, being lightweight and flexible, allows for easier handling and faster placement, reducing overall installation complexity and expenses. Practicality favors glass fiber in projects demanding quick turnaround and less structural modification, while steel fiber is preferred in applications needing superior tensile strength and impact resistance despite installation challenges.

Environmental Impact and Sustainability

Steel fiber offers higher recyclability and longer lifespan compared to glass fiber, reducing environmental waste and resource consumption. Glass fiber production involves higher energy use and emits more greenhouse gases, whereas steel fibers can be sourced from recycled scrap metal, enhancing sustainability. Both materials require careful end-of-life management, but steel fiber's durability and recyclability provide a significant advantage in reducing the carbon footprint of construction projects.

Selecting the Right Fiber: Key Factors to Consider

When selecting between steel fiber and glass fiber, consider factors such as tensile strength, corrosion resistance, and application environment. Steel fibers offer superior impact resistance and durability for heavy-duty construction, while glass fibers provide lightweight, non-corrosive reinforcement suitable for thermal insulation and aesthetic applications. Evaluating load requirements, exposure conditions, and cost-effectiveness ensures optimal fiber choice for structural performance and longevity.

Tensile strength differential

Steel fiber exhibits significantly higher tensile strength, typically ranging from 1200 to 2500 MPa, compared to glass fiber's tensile strength of approximately 2000 to 3500 MPa, with steel fiber providing superior ductility and impact resistance in composite applications.

Modulus of elasticity

Steel fiber exhibits a significantly higher modulus of elasticity, typically around 200 GPa, compared to glass fiber, which ranges from 70 to 90 GPa, indicating superior stiffness and load-bearing capacity in reinforced composites.

Crack bridging

Steel fibers provide superior crack bridging in concrete due to their higher tensile strength and ductility compared to glass fibers.

Flexural toughness

Steel fiber-reinforced concrete exhibits higher flexural toughness compared to glass fiber-reinforced concrete due to its superior crack-bridging capacity and energy absorption characteristics.

Corrosion resistance

Steel fiber exhibits lower corrosion resistance compared to glass fiber, making glass fiber more suitable for applications exposed to humid or chemically aggressive environments.

Alkali resistance

Steel fiber exhibits superior alkali resistance compared to glass fiber, making it more durable in alkaline environments commonly found in concrete structures.

Fiber-matrix bonding

Steel fiber exhibits superior fiber-matrix bonding compared to glass fiber due to its rough surface texture and higher tensile strength, enhancing composite durability and load transfer efficiency.

Impact resistance

Steel fiber reinforcement provides significantly higher impact resistance than glass fiber due to its superior tensile strength and energy absorption capacity.

Shrinkage control

Steel fiber provides superior shrinkage control in concrete compared to glass fiber due to its higher tensile strength and better crack resistance.

Hybrid fiber reinforcement

Hybrid fiber reinforcement combining steel fiber's high tensile strength with glass fiber's superior corrosion resistance significantly enhances concrete's durability and crack control.

Steel fiber vs Glass fiber Infographic

njnir.com

njnir.com