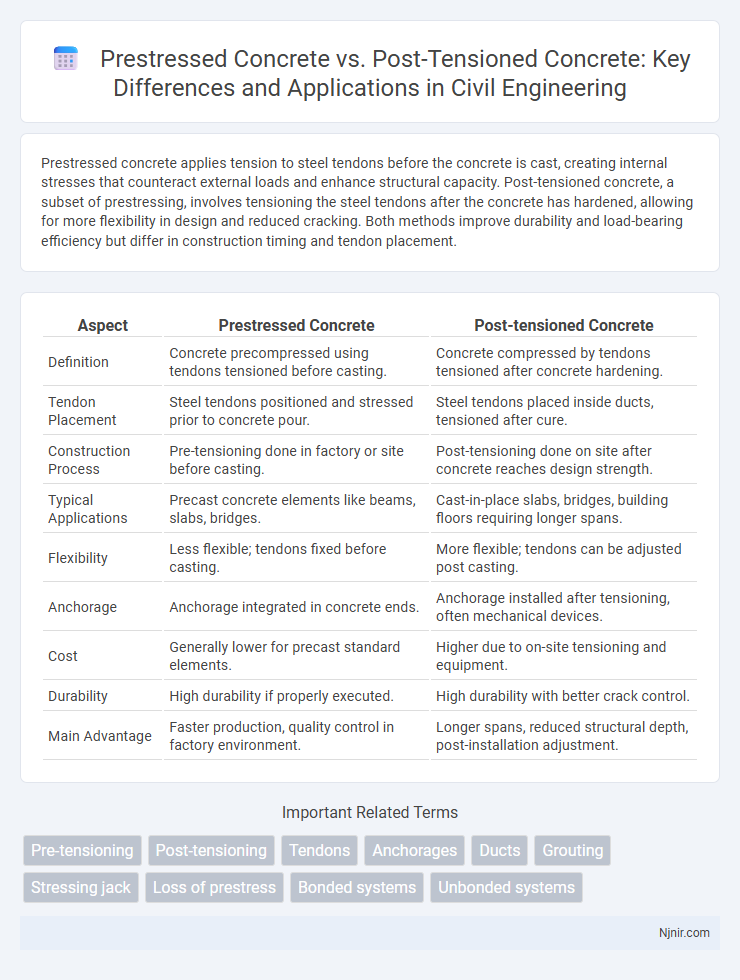

Prestressed concrete applies tension to steel tendons before the concrete is cast, creating internal stresses that counteract external loads and enhance structural capacity. Post-tensioned concrete, a subset of prestressing, involves tensioning the steel tendons after the concrete has hardened, allowing for more flexibility in design and reduced cracking. Both methods improve durability and load-bearing efficiency but differ in construction timing and tendon placement.

Table of Comparison

| Aspect | Prestressed Concrete | Post-tensioned Concrete |

|---|---|---|

| Definition | Concrete precompressed using tendons tensioned before casting. | Concrete compressed by tendons tensioned after concrete hardening. |

| Tendon Placement | Steel tendons positioned and stressed prior to concrete pour. | Steel tendons placed inside ducts, tensioned after cure. |

| Construction Process | Pre-tensioning done in factory or site before casting. | Post-tensioning done on site after concrete reaches design strength. |

| Typical Applications | Precast concrete elements like beams, slabs, bridges. | Cast-in-place slabs, bridges, building floors requiring longer spans. |

| Flexibility | Less flexible; tendons fixed before casting. | More flexible; tendons can be adjusted post casting. |

| Anchorage | Anchorage integrated in concrete ends. | Anchorage installed after tensioning, often mechanical devices. |

| Cost | Generally lower for precast standard elements. | Higher due to on-site tensioning and equipment. |

| Durability | High durability if properly executed. | High durability with better crack control. |

| Main Advantage | Faster production, quality control in factory environment. | Longer spans, reduced structural depth, post-installation adjustment. |

Introduction to Prestressed and Post-tensioned Concrete

Prestressed concrete enhances structural capacity by inducing internal stresses through pre-applied tension, counteracting service loads and minimizing tensile stresses. Post-tensioned concrete involves tensioning steel tendons after concrete curing, allowing for thinner slabs and longer spans with improved crack control. Both techniques optimize material efficiency and durability in modern construction.

Basic Principles and Definitions

Prestressed concrete involves applying compressive stresses to the concrete before it carries any external loads, achieved through pre-tensioning or post-tensioning techniques. Post-tensioned concrete is a specific type of prestressed concrete where high-strength steel tendons are tensioned after the concrete has hardened, creating compression that counteracts tensile forces under service loads. These methods enhance structural capacity, reduce material usage, and improve crack resistance compared to conventional reinforced concrete.

Materials and Components Used

Prestressed concrete primarily uses high-strength steel wires or strands that are tensioned before the concrete is cast, embedding the tension internally to counteract loads. Post-tensioned concrete involves steel tendons placed within ducts inside the concrete, which are tensioned after the concrete has hardened, allowing more control over stress distribution. Both methods require high-quality concrete mix and corrosion-resistant ducts or sheaths to protect the steel components, ensuring durability and structural integrity.

Construction Techniques and Methods

Prestressed concrete employs high-strength steel tendons tensioned before the application of external loads, typically using pre-tensioning methods where tendons are stressed prior to casting concrete. Post-tensioned concrete involves casting concrete around untensioned ducts, followed by tensioning steel tendons after the concrete hardens, allowing for precise control of stress levels in-situ. Both methods enhance structural capacity and durability but differ in installation complexity and suitability for various construction scales and shapes.

Structural Advantages and Limitations

Prestressed concrete utilizes pre-tensioned steel strands to apply compressive forces before load application, enhancing crack resistance and structural stiffness for bridges and buildings. Post-tensioned concrete features tendon tensioning after concrete hardening, enabling longer spans, thinner slabs, and reduced material use, which optimizes load distribution and deflection control. Limitations of prestressed concrete include susceptibility to strand corrosion and complexity in formwork, while post-tensioned concrete requires precise tensioning systems and poses challenges in maintenance and inspection.

Applications in Modern Civil Engineering

Prestressed concrete is widely used in bridges, parking garages, and high-rise buildings due to its ability to handle heavy loads and resist tensile stresses. Post-tensioned concrete, a form of prestressing where tendons are tensioned after the concrete sets, is especially effective in slab-on-grade floors, long-span slabs, and curved structural elements, offering greater design flexibility and material efficiency. Both techniques improve structural performance and durability, but post-tensioning is preferred for projects requiring thinner slabs and complex geometries in modern civil engineering.

Cost Comparison and Economic Considerations

Prestressed concrete generally incurs higher initial costs due to the extensive use of high-strength steel tendons and complex fabrication processes, while post-tensioned concrete can offer cost savings through reduced concrete volume and lighter structural elements. Economic considerations often favor post-tensioning in projects requiring longer spans and thinner slabs, resulting in lower material and labor expenses. Lifecycle cost analysis typically shows that despite higher upfront costs, prestressed concrete may provide better durability and reduced maintenance costs over time.

Durability and Maintenance Requirements

Prestressed concrete, with its pre-applied tensioning cables, offers enhanced durability by minimizing crack formation and resisting environmental stressors, reducing the need for frequent maintenance. Post-tensioned concrete allows for adjustable tension after curing, which can improve structural performance but may require periodic inspections and maintenance of anchorage systems to prevent corrosion and ensure longevity. Both methods extend service life compared to traditional concrete, but post-tensioned concrete demands more vigilant maintenance to sustain durability over time.

Safety and Performance Analysis

Prestressed concrete involves tensioning the steel tendons before casting, enhancing structural capacity and reducing cracking, which improves overall safety under high loads. Post-tensioned concrete allows for adjustments after the concrete has hardened, offering superior control over deflections and increased resistance to shear and bending stresses, leading to enhanced performance in long-span structures. Safety analysis highlights that post-tensioned systems can better accommodate dynamic loads and seismic activity due to their flexibility and precise tensioning capabilities.

Future Trends in Prestressed and Post-tensioned Concrete

Advancements in prestressed and post-tensioned concrete emphasize sustainability through the integration of high-performance materials and eco-friendly admixtures that enhance durability while reducing carbon footprints. Innovations in smart monitoring systems utilizing embedded sensors enable real-time stress and strain analysis, optimizing structural health and maintenance schedules. The adoption of automated tensioning techniques and precast modular components accelerates construction timelines and improves precision in large-scale infrastructure projects.

Pre-tensioning

Pre-tensioned concrete involves casting concrete around steel tendons that are tensioned before placement, providing higher early strength and improved crack resistance compared to post-tensioned concrete where tendons are tensioned after curing.

Post-tensioning

Post-tensioned concrete uses high-strength steel tendons tensioned after concrete curing, providing enhanced strength, reduced cracking, and greater design flexibility compared to prestressed concrete's pre-tensioning process.

Tendons

Prestressed concrete uses pre-tensioned tendons tensioned before casting, while post-tensioned concrete employs tendons tensioned after the concrete hardens, enhancing structural strength and flexibility.

Anchorages

Anchorages in prestressed concrete are embedded during casting to hold tendons under tension, while post-tensioned concrete uses external or cast-in anchorages applied after concrete curing to secure tendons, enabling adjustable tensioning and improved structural performance.

Ducts

Ducts in prestressed concrete are typically embedded before tensioning the steel tendons, whereas in post-tensioned concrete, ducts are cast into the concrete first and tendons are tensioned afterward through these ducts.

Grouting

Grouting in post-tensioned concrete is crucial for corrosion protection and bond strength, whereas prestressed concrete typically uses pre-tensioning with no grouting involved.

Stressing jack

Stressing jacks in prestressed concrete apply tension to steel tendons before concrete casting, while in post-tensioned concrete, they tension tendons after concrete hardening, enabling precise stress control and enhanced structural performance.

Loss of prestress

Loss of prestress in prestressed concrete typically occurs due to elastic shortening, creep, shrinkage, and relaxation, whereas post-tensioned concrete experiences additional losses from anchorage set and friction during tendon stressing.

Bonded systems

Bonded prestressed concrete integrates tendons embedded in grout within ducts to ensure corrosion protection and load transfer, whereas bonded post-tensioned concrete employs similar grout-encased tendons energized after concrete curing for enhanced structural performance and durability.

Unbonded systems

Unbonded post-tensioned concrete systems utilize individual strands coated with grease and encased in plastic sheaths, allowing for greater flexibility and easier maintenance compared to bonded prestressed concrete where strands are directly bonded to the concrete.

Prestressed Concrete vs Post-tensioned Concrete Infographic

njnir.com

njnir.com