Modular construction offers significant time savings by enabling simultaneous on-site preparation and off-site module fabrication, reducing project durations compared to conventional construction. Enhanced quality control is achieved in factory settings, minimizing defects and improving overall building performance. Cost-effectiveness arises from less material waste and decreased labor requirements, making modular methods a sustainable alternative to traditional construction.

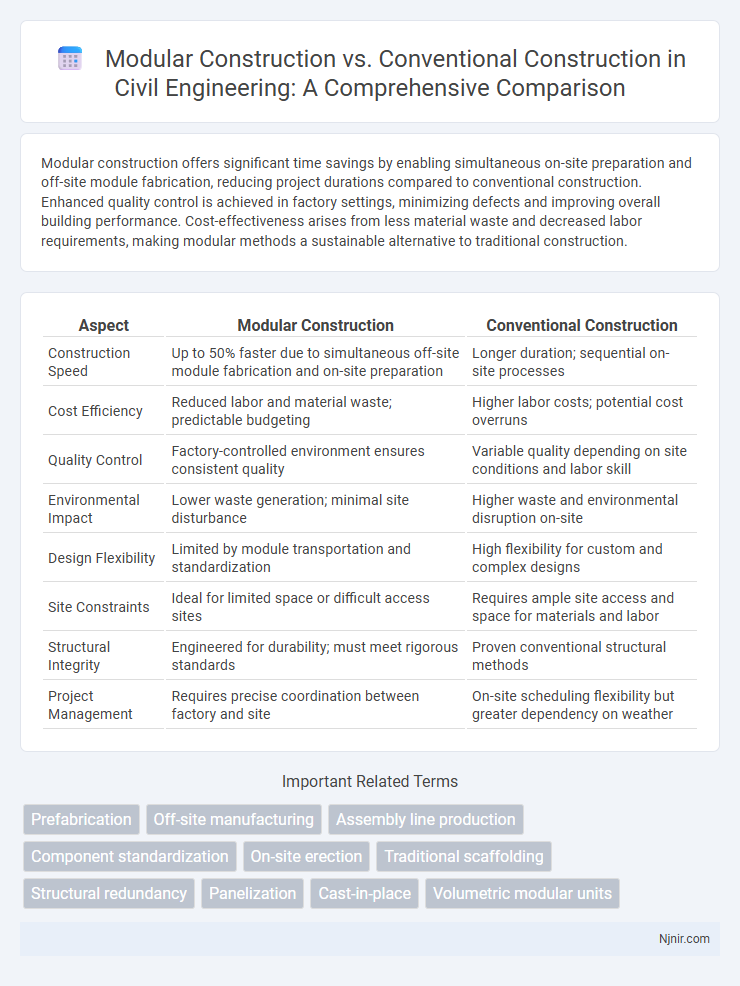

Table of Comparison

| Aspect | Modular Construction | Conventional Construction |

|---|---|---|

| Construction Speed | Up to 50% faster due to simultaneous off-site module fabrication and on-site preparation | Longer duration; sequential on-site processes |

| Cost Efficiency | Reduced labor and material waste; predictable budgeting | Higher labor costs; potential cost overruns |

| Quality Control | Factory-controlled environment ensures consistent quality | Variable quality depending on site conditions and labor skill |

| Environmental Impact | Lower waste generation; minimal site disturbance | Higher waste and environmental disruption on-site |

| Design Flexibility | Limited by module transportation and standardization | High flexibility for custom and complex designs |

| Site Constraints | Ideal for limited space or difficult access sites | Requires ample site access and space for materials and labor |

| Structural Integrity | Engineered for durability; must meet rigorous standards | Proven conventional structural methods |

| Project Management | Requires precise coordination between factory and site | On-site scheduling flexibility but greater dependency on weather |

Introduction to Modular and Conventional Construction

Modular construction involves prefabricating building components in a factory setting before assembling them on-site, offering significant time and cost efficiencies compared to conventional construction, which involves on-site, step-by-step building processes. This method enhances quality control, reduces waste, and minimizes weather-related delays commonly faced in traditional construction projects. Conventional construction remains prevalent due to its flexibility in customization and familiarity among contractors, but modular construction is rapidly gaining traction in residential, commercial, and industrial sectors for its scalability and sustainability benefits.

Key Differences Between Modular and Conventional Methods

Modular construction involves fabricating building components off-site in controlled factory settings, enabling faster project timelines and reduced on-site labor. Conventional construction relies on assembling structures entirely on-site, often resulting in longer schedules and increased exposure to weather-related delays. Energy efficiency and waste reduction are typically higher with modular methods due to precise factory production and standardized processes.

Speed of Construction: Modular vs Conventional

Modular construction significantly reduces project timelines by up to 50% compared to conventional construction due to simultaneous off-site fabrication and on-site preparation. Factory-controlled environments minimize weather-related delays and optimize labor efficiency, accelerating overall delivery. Conventional methods rely heavily on sequential on-site processes, often extending construction duration and increasing susceptibility to schedule disruptions.

Cost Comparison: Modular and Traditional Approaches

Modular construction reduces costs by up to 20% compared to conventional methods through streamlined factory processes and minimized on-site labor expenses. Traditional construction often incurs higher overhead due to extended project timelines, weather delays, and material waste. The controlled environment of modular fabrication ensures predictable budgets and faster project delivery, optimizing overall cost efficiency.

Quality Control in Modular and Conventional Construction

Modular construction offers enhanced quality control through factory-based manufacturing processes that ensure consistent materials and precise assembly under regulated conditions. Conventional construction relies on on-site work, which can lead to variable quality influenced by weather, labor skills, and site conditions. Factory settings in modular construction minimize defects and improve compliance with industry standards compared to the decentralized quality control of conventional methods.

Sustainability and Environmental Impact

Modular construction significantly reduces waste by up to 90% compared to conventional construction methods, as precise factory settings optimize material usage and allow recycling of offcuts. Energy consumption during the building process is lowered due to shorter on-site construction times and minimized machinery operation, decreasing carbon emissions substantially. Furthermore, modular buildings are designed for adaptability and disassembly, facilitating reuse or recycling of components, which enhances their overall environmental sustainability.

Labor Requirements and Workforce Implications

Modular construction significantly reduces on-site labor requirements by shifting a large portion of the building process to controlled factory environments, resulting in streamlined workflows and decreased dependency on skilled trades at the construction site. Conventional construction demands a higher volume of on-site labor, often leading to variable productivity due to weather conditions, coordination challenges, and labor shortages. The modular approach mitigates workforce fluctuations by enabling simultaneous off-site manufacturing and on-site preparation, enhancing overall project efficiency and labor resource management.

Design Flexibility and Architectural Limitations

Modular construction offers enhanced design flexibility by allowing prefabricated components to be easily configured and customized to meet various architectural needs, accelerating project timelines and reducing on-site labor. Conventional construction, while providing greater freedom for complex and unique designs, often faces limitations in efficiency and increased costs due to the labor-intensive, sequential building process. Architectural limitations in modular construction primarily stem from transportation constraints and factory production standards, which can restrict size and shape variations compared to the more adaptable conventional methods.

Safety Considerations in Both Construction Methods

Modular construction significantly enhances safety by minimizing on-site work, reducing exposure to hazards such as falls and heavy machinery accidents commonly associated with conventional construction. Factory settings used in modular construction follow strict safety protocols, controlled environments, and standardized processes, which lower the risk of injuries. In contrast, conventional construction involves variable site conditions and weather influences that often increase workplace accidents, necessitating rigorous safety training and personal protective equipment (PPE) use to mitigate risks.

Future Trends in Modular and Conventional Construction

Future trends in modular construction emphasize increased automation, enhanced use of digital twin technology, and expansion into high-rise and complex structures, driven by the demand for faster project delivery and sustainability. Conventional construction is evolving through greater integration of IoT devices for real-time project monitoring and advanced materials like self-healing concrete to improve durability and reduce maintenance costs. Both sectors are increasingly adopting environmentally friendly practices, with modular construction leveraging off-site fabrication to minimize waste and conventional methods integrating green building certifications to meet global carbon reduction targets.

Prefabrication

Modular construction significantly reduces build time and waste through extensive prefabrication in controlled factory settings compared to conventional construction's on-site assembly.

Off-site manufacturing

Off-site manufacturing in modular construction reduces project timelines by up to 50% and minimizes material waste by 30% compared to conventional construction methods.

Assembly line production

Modular construction leverages assembly line production to enhance efficiency, reduce construction time by up to 50%, and minimize onsite labor compared to conventional construction methods.

Component standardization

Modular construction significantly enhances project efficiency and quality control through component standardization compared to the variability often found in conventional construction methods.

On-site erection

Modular construction reduces on-site erection time by up to 60%, significantly minimizing labor costs and weather-related delays compared to conventional construction methods.

Traditional scaffolding

Modular construction reduces reliance on traditional scaffolding by enabling off-site prefabrication, increasing safety and efficiency compared to conventional construction methods.

Structural redundancy

Modular construction enhances structural redundancy by integrating prefabricated, standardized components that increase load distribution and fault tolerance compared to conventional construction's site-built, custom structures.

Panelization

Panelization in modular construction reduces onsite labor and construction time by fabricating building components offsite, offering higher precision and waste reduction compared to conventional construction methods.

Cast-in-place

Cast-in-place construction, a traditional method involving on-site concrete pouring, offers superior customization and structural integrity compared to modular construction's prefabricated components.

Volumetric modular units

Volumetric modular units in modular construction reduce project timelines by up to 50% and lower labor costs by 30% compared to conventional construction methods.

modular construction vs conventional construction Infographic

njnir.com

njnir.com