Steel fiber concrete enhances tensile strength and crack resistance by distributing fibers throughout the matrix, offering improved durability and impact resistance compared to traditional rebar reinforced concrete. Unlike rebar reinforcement, which provides localized strength primarily along predetermined lines, steel fibers act as micro-reinforcements that control shrinkage and reduce microcracking. This results in a more uniform load transfer and increased toughness, making steel fiber concrete particularly advantageous in applications requiring high abrasion resistance and complex geometries.

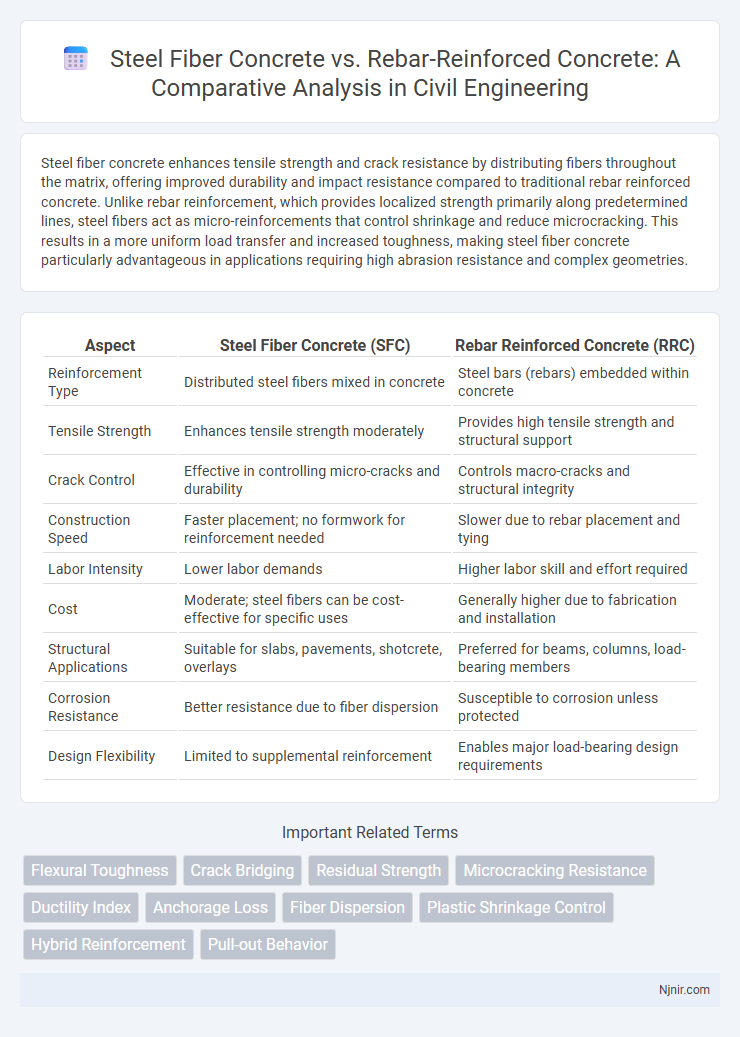

Table of Comparison

| Aspect | Steel Fiber Concrete (SFC) | Rebar Reinforced Concrete (RRC) |

|---|---|---|

| Reinforcement Type | Distributed steel fibers mixed in concrete | Steel bars (rebars) embedded within concrete |

| Tensile Strength | Enhances tensile strength moderately | Provides high tensile strength and structural support |

| Crack Control | Effective in controlling micro-cracks and durability | Controls macro-cracks and structural integrity |

| Construction Speed | Faster placement; no formwork for reinforcement needed | Slower due to rebar placement and tying |

| Labor Intensity | Lower labor demands | Higher labor skill and effort required |

| Cost | Moderate; steel fibers can be cost-effective for specific uses | Generally higher due to fabrication and installation |

| Structural Applications | Suitable for slabs, pavements, shotcrete, overlays | Preferred for beams, columns, load-bearing members |

| Corrosion Resistance | Better resistance due to fiber dispersion | Susceptible to corrosion unless protected |

| Design Flexibility | Limited to supplemental reinforcement | Enables major load-bearing design requirements |

Overview of Steel Fiber Concrete and Rebar Reinforced Concrete

Steel Fiber Concrete incorporates steel fibers to enhance tensile strength, crack resistance, and durability, making it ideal for applications requiring impact and fatigue resistance. Rebar Reinforced Concrete embeds steel bars within the concrete matrix, providing substantial structural support and improved load-bearing capacity for heavy construction projects. Both materials offer distinct advantages in structural performance, with steel fibers improving ductility and rebar ensuring robust reinforcement.

Material Composition and Types

Steel fiber concrete incorporates dispersed short steel fibers uniformly mixed within the concrete matrix, enhancing tensile strength and crack resistance, while rebar reinforced concrete uses long steel bars embedded in specific orientations to provide structural support. Steel fibers typically vary in length from 30 to 60 mm and are made from high-carbon steel or stainless steel, whereas rebar is manufactured in grades like ASTM A615 and ranges in diameter from 6 mm to 40 mm. The choice between steel fibers and rebar depends on project requirements, with steel fibers offering improved impact resistance and ease of placement, and rebar providing superior load-bearing capacity and ductility.

Structural Performance Comparison

Steel fiber concrete enhances tensile strength and crack resistance by distributing stress more evenly compared to traditional rebar reinforced concrete. It provides improved impact resistance and durability under dynamic loading, reducing the likelihood of structural failure in seismic or heavy-load conditions. While rebar reinforced concrete offers superior flexural strength and load-bearing capacity in large-scale applications, steel fiber concrete excels in reducing micro-cracking and improving toughness in slabs and precast elements.

Crack Control and Durability

Steel fiber concrete offers superior crack control by distributing microfibers uniformly, reducing crack widths and enhancing tensile strength compared to traditional rebar reinforced concrete, which relies on localized reinforcement. Durability in steel fiber concrete is improved through increased resistance to impact, fatigue, and corrosion, whereas rebar embedded in concrete is susceptible to corrosion over time, potentially compromising structural integrity. The integration of steel fibers results in a more homogeneous matrix, leading to longer service life and reduced maintenance costs in aggressive environments.

Load-Bearing Capacity Analysis

Steel fiber concrete enhances load-bearing capacity by distributing stresses more evenly and improving crack resistance, whereas rebar reinforced concrete primarily relies on steel bars to handle tensile forces. Studies show steel fiber concrete can increase flexural strength by up to 30%, leading to better energy absorption and ductility during load application. Rebar reinforcement provides predictable load paths and high tensile performance, but steel fibers offer improved post-crack load-bearing behavior and reduced spalling under high stress conditions.

Flexural and Tensile Strength Differences

Steel fiber concrete demonstrates superior flexural strength due to the uniform distribution of fibers that arrest crack propagation, resulting in enhanced post-crack ductility compared to traditional rebar reinforced concrete. Tensile strength in steel fiber concrete is improved through fiber bridging effects that provide resistance to crack widening, whereas rebar reinforced concrete relies on discrete steel bars to bear tensile loads, potentially creating localized stress concentrations. Studies indicate that steel fiber concrete can achieve up to 30% higher tensile strength and significantly better flexural toughness, offering improved performance in applications requiring crack control and durability.

Installation and Construction Methods

Steel fiber concrete simplifies installation by eliminating the need for placing and tying traditional rebar, reducing labor time and costs on-site. Rebar reinforced concrete requires precise placement, bending, and securing of steel bars before pouring, which demands skilled labor and additional equipment. The ease of mixing steel fibers directly into the concrete enhances construction speed and uniformity compared to the more tedious process of assembling rebar cages.

Cost Implications and Economic Considerations

Steel fiber concrete reduces labor costs and installation time compared to rebar reinforced concrete, as fibers are mixed directly into the concrete, eliminating the need for complex steel placement. Material costs for steel fibers can be higher per unit weight than traditional rebar, but overall project expenses often decrease due to simplified logistics and decreased construction durations. Economic considerations also include improved crack resistance and durability in steel fiber concrete, potentially lowering long-term maintenance and repair costs relative to conventional rebar reinforcement.

Applications in Modern Civil Engineering Projects

Steel fiber concrete enhances crack resistance and impact toughness, making it ideal for industrial floors, tunnel linings, and precast elements where durability and reduced maintenance are critical. Rebar reinforced concrete remains preferred for structural components like beams, columns, and bridges due to its superior tensile strength and load-bearing capacity. Combining steel fibers with rebar can optimize performance in complex infrastructure projects, improving structural integrity and extending service life in modern civil engineering applications.

Environmental Impact and Sustainability

Steel fiber concrete reduces environmental impact by minimizing the need for extensive formwork and lowering cement usage due to enhanced crack resistance, resulting in decreased CO2 emissions compared to traditional rebar reinforced concrete. The production of steel fibers consumes less energy and raw materials than manufacturing conventional rebar, contributing to greater sustainability in construction projects. Enhanced durability and reduced maintenance of steel fiber concrete extend the lifespan of structures, further lessening environmental footprints over time.

Flexural Toughness

Steel fiber concrete demonstrates significantly higher flexural toughness than rebar reinforced concrete, enhancing crack resistance and energy absorption under bending stresses.

Crack Bridging

Steel fiber concrete provides superior crack bridging performance by distributing tensile stresses more evenly and reducing crack widths compared to rebar reinforced concrete, which primarily controls cracking through discrete, localized reinforcement points.

Residual Strength

Steel fiber concrete demonstrates superior residual strength compared to rebar reinforced concrete, maintaining higher load-bearing capacity and crack resistance after initial cracking.

Microcracking Resistance

Steel fiber concrete exhibits superior microcracking resistance compared to rebar reinforced concrete due to its uniformly distributed fibers that effectively bridge cracks and enhance tensile strength.

Ductility Index

Steel fiber concrete exhibits a higher ductility index than rebar reinforced concrete, enhancing its ability to absorb energy and deform without sudden failure.

Anchorage Loss

Steel fiber concrete reduces anchorage loss more effectively than rebar reinforced concrete by distributing stresses evenly and enhancing crack control through micro-reinforcement.

Fiber Dispersion

Steel fiber concrete offers improved fiber dispersion throughout the mix, resulting in enhanced crack resistance and uniform stress distribution compared to the localized reinforcement provided by rebar in reinforced concrete.

Plastic Shrinkage Control

Steel fiber concrete reduces plastic shrinkage cracking more effectively than rebar reinforced concrete by distributing tensile stresses throughout the matrix.

Hybrid Reinforcement

Hybrid reinforcement combining steel fibers and rebar in concrete enhances tensile strength, crack control, and durability compared to using either steel fiber concrete or rebar reinforced concrete alone.

Pull-out Behavior

Steel fiber concrete demonstrates superior pull-out resistance and crack control compared to rebar reinforced concrete due to the enhanced bonding and distributed stress transfer provided by dispersed fibers.

Steel Fiber Concrete vs Rebar Reinforced Concrete Infographic

njnir.com

njnir.com