Recycled aggregates offer an environmentally sustainable alternative to natural aggregates by reducing construction waste and conserving natural resources. They often exhibit comparable strength and durability, making them suitable for various structural applications in civil engineering. Careful quality control is essential to address variability and ensure performance consistency in recycled aggregate materials.

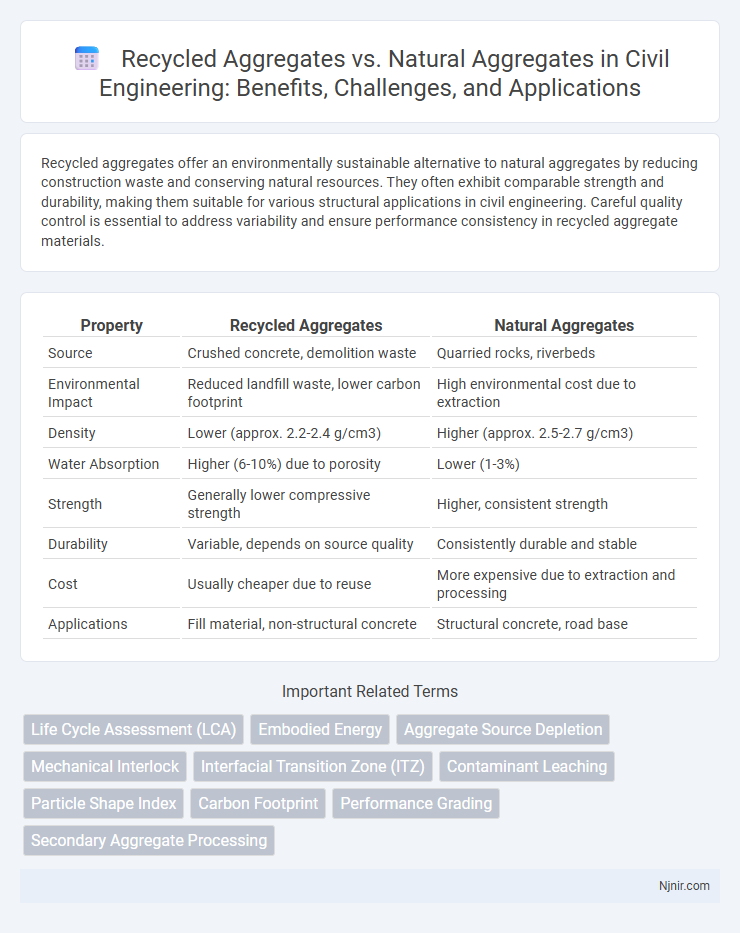

Table of Comparison

| Property | Recycled Aggregates | Natural Aggregates |

|---|---|---|

| Source | Crushed concrete, demolition waste | Quarried rocks, riverbeds |

| Environmental Impact | Reduced landfill waste, lower carbon footprint | High environmental cost due to extraction |

| Density | Lower (approx. 2.2-2.4 g/cm3) | Higher (approx. 2.5-2.7 g/cm3) |

| Water Absorption | Higher (6-10%) due to porosity | Lower (1-3%) |

| Strength | Generally lower compressive strength | Higher, consistent strength |

| Durability | Variable, depends on source quality | Consistently durable and stable |

| Cost | Usually cheaper due to reuse | More expensive due to extraction and processing |

| Applications | Fill material, non-structural concrete | Structural concrete, road base |

Introduction to Aggregates in Civil Engineering

Natural aggregates, sourced from quarried rock, sand, and gravel, serve as fundamental materials in civil engineering for concrete, asphalt, and road construction due to their strength and availability. Recycled aggregates, derived from processed construction and demolition waste, offer sustainable alternatives by reducing landfill use and conserving natural resources while meeting standards for many structural applications. Performance differences such as moisture absorption, density, and durability require careful evaluation when selecting recycled aggregates for specific civil engineering projects.

Definition and Types of Recycled Aggregates

Recycled aggregates are materials derived from the processing of construction and demolition waste, including crushed concrete, bricks, asphalt, and mixed debris, used as a sustainable alternative to natural aggregates extracted from quarries. Types of recycled aggregates include recycled concrete aggregate (RCA), reclaimed asphalt pavement (RAP), recycled brick aggregate, and mixed recycled aggregate, each varying in composition and suitability for construction applications. These materials reduce the environmental impact of quarrying by promoting resource efficiency and minimizing landfill waste.

Characteristics of Natural Aggregates

Natural aggregates consist primarily of sand, gravel, and crushed stone, characterized by high strength, durability, and consistent gradation. Their mineral composition varies depending on geological origin, influencing properties such as absorption, density, and abrasion resistance. These aggregates typically exhibit lower contaminants and higher load-bearing capacity compared to recycled alternatives.

Environmental Impact: Recycled vs Natural Aggregates

Recycled aggregates significantly reduce environmental impact by lowering the demand for virgin raw materials and minimizing landfill waste, conserving natural resources and reducing greenhouse gas emissions. Natural aggregates require extensive quarrying, which leads to habitat disruption, biodiversity loss, and increased carbon footprint due to extraction and transportation processes. Utilizing recycled aggregates supports sustainable construction practices by promoting circular economy principles and reducing overall ecological damage.

Mechanical Properties Comparison

Recycled aggregates generally exhibit lower compressive strength and higher water absorption compared to natural aggregates due to the presence of old mortar and micro-cracks. Natural aggregates provide superior density and improved mechanical interlocking, resulting in enhanced load-bearing capacity and durability in concrete applications. Advances in processing recycled aggregates aim to reduce these mechanical property gaps, promoting sustainable construction without significantly compromising structural performance.

Cost Analysis and Economic Feasibility

Recycled aggregates typically offer a cost advantage over natural aggregates due to lower material and transportation expenses, especially in urban areas where demolition waste is readily available. Economic feasibility improves when considering savings on landfill fees and reduced environmental compliance costs associated with quarrying natural aggregates. However, variability in quality and processing requirements of recycled aggregates can influence overall project costs and must be factored into a comprehensive cost-benefit analysis.

Performance in Concrete and Asphalt Applications

Recycled aggregates demonstrate comparable performance to natural aggregates in concrete and asphalt applications, offering similar compressive strength and durability when properly processed and tested. In concrete, recycled aggregates maintain adequate workability and reduce environmental impact by lowering demand for virgin materials. Asphalt mixtures incorporating recycled aggregates show enhanced resistance to rutting and fatigue, contributing to sustainable infrastructure development with effective load-bearing capacity.

Standards and Specifications

Recycled aggregates must comply with stringent standards such as ASTM C33 and EN 12620, which specify limits for contaminants and physical properties to ensure structural integrity comparable to natural aggregates. Natural aggregates adhere to well-established specifications like ASTM C33, which define particle size distribution, cleanliness, and strength parameters critical for construction applications. Quality control protocols for recycled aggregates often include additional testing for contaminants like chlorides, sulfates, and organic materials, reflecting stricter environmental and safety requirements than those for natural aggregates.

Challenges and Limitations

Recycled aggregates often present challenges such as lower mechanical strength and higher water absorption compared to natural aggregates, affecting concrete durability and performance. Variability in quality and contamination from adhered mortar or impurities limits their consistent use in structural applications. Strict regulatory standards and lack of uniform classification systems further constrain widespread adoption in construction projects.

Future Trends in Aggregate Utilization

Future trends in aggregate utilization emphasize an increasing shift towards recycled aggregates due to sustainability goals and stringent environmental regulations. Innovations in processing technologies are improving the quality and consistency of recycled aggregates, making them more competitive with natural aggregates in construction applications. The integration of digital monitoring and lifecycle assessment tools further supports the optimized use of recycled materials to reduce carbon footprints in infrastructure projects.

Life Cycle Assessment (LCA)

Life Cycle Assessment (LCA) reveals recycled aggregates significantly reduce environmental impacts compared to natural aggregates by lowering carbon emissions, energy consumption, and resource depletion throughout their production and use phases.

Embodied Energy

Recycled aggregates significantly reduce embodied energy compared to natural aggregates by minimizing energy-intensive extraction and processing in construction materials.

Aggregate Source Depletion

Recycled aggregates mitigate natural aggregate source depletion by reusing construction and demolition waste, reducing the demand for virgin materials and preserving natural resources.

Mechanical Interlock

Recycled aggregates exhibit lower mechanical interlock compared to natural aggregates due to their irregular shape and surface texture, impacting concrete's overall strength and durability.

Interfacial Transition Zone (ITZ)

Recycled aggregates exhibit a more porous and weaker Interfacial Transition Zone (ITZ) compared to natural aggregates, significantly influencing concrete's mechanical strength and durability.

Contaminant Leaching

Recycled aggregates exhibit a higher risk of contaminant leaching compared to natural aggregates due to the presence of adhered mortar and potential impurities from construction and demolition waste.

Particle Shape Index

Recycled aggregates typically exhibit a higher Particle Shape Index than natural aggregates, indicating more angular and irregular particle shapes that can affect concrete workability and strength.

Carbon Footprint

Recycled aggregates reduce carbon footprint by up to 40% compared to natural aggregates due to lower extraction and processing emissions.

Performance Grading

Recycled aggregates exhibit comparable performance grading to natural aggregates in terms of durability, load-bearing capacity, and moisture resistance, making them a sustainable alternative for construction applications.

Secondary Aggregate Processing

Secondary aggregate processing enhances recycled aggregates by improving particle quality and reducing contaminants, making them comparable to natural aggregates for construction use.

recycled aggregates vs natural aggregates Infographic

njnir.com

njnir.com