Fly ash and GGBS are widely used supplementary cementitious materials in civil engineering that enhance concrete durability and sustainability. Fly ash improves workability and reduces heat of hydration, while GGBS offers superior strength development and resistance to chemical attack. Selecting between fly ash and GGBS depends on project requirements such as setting time, environmental conditions, and long-term performance goals.

Table of Comparison

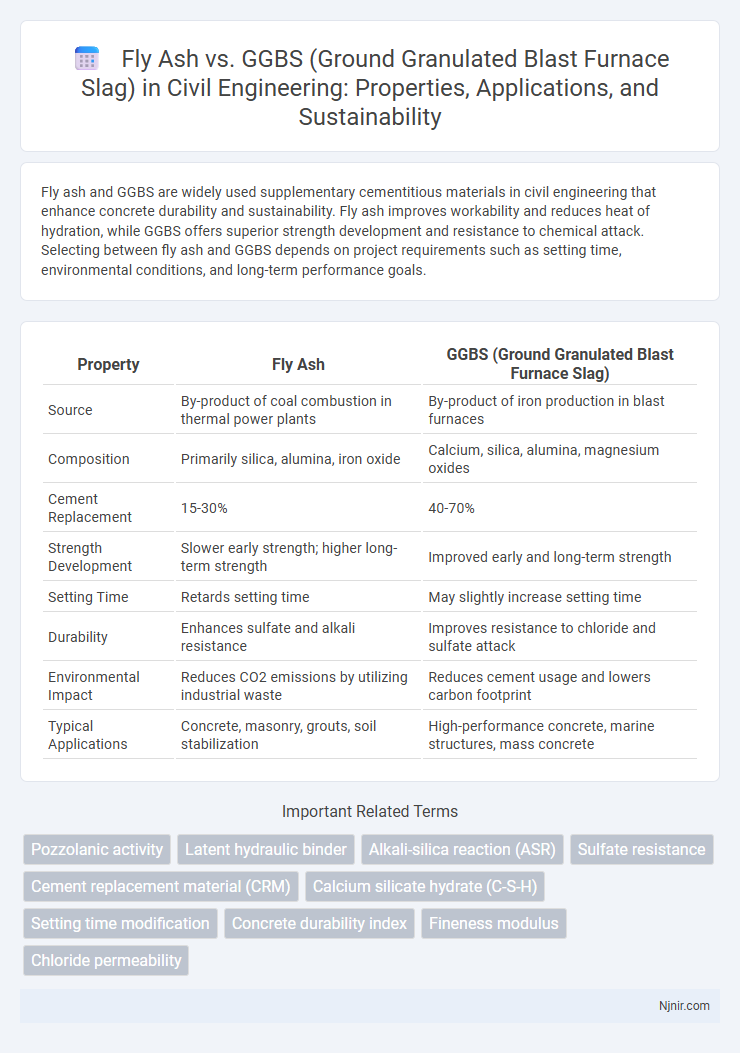

| Property | Fly Ash | GGBS (Ground Granulated Blast Furnace Slag) |

|---|---|---|

| Source | By-product of coal combustion in thermal power plants | By-product of iron production in blast furnaces |

| Composition | Primarily silica, alumina, iron oxide | Calcium, silica, alumina, magnesium oxides |

| Cement Replacement | 15-30% | 40-70% |

| Strength Development | Slower early strength; higher long-term strength | Improved early and long-term strength |

| Setting Time | Retards setting time | May slightly increase setting time |

| Durability | Enhances sulfate and alkali resistance | Improves resistance to chloride and sulfate attack |

| Environmental Impact | Reduces CO2 emissions by utilizing industrial waste | Reduces cement usage and lowers carbon footprint |

| Typical Applications | Concrete, masonry, grouts, soil stabilization | High-performance concrete, marine structures, mass concrete |

Introduction to Fly Ash and GGBS

Fly ash is a fine powder byproduct from burning pulverized coal in thermal power plants, rich in silica, alumina, and iron, which enhances concrete durability and workability. Ground Granulated Blast Furnace Slag (GGBS) is a cementitious material produced by quenching molten iron slag from blast furnaces, known for improving concrete strength and reducing permeability. Both fly ash and GGBS are sustainable supplementary cementitious materials that contribute to lower carbon footprints in construction.

Chemical Composition: Fly Ash vs GGBS

Fly ash primarily contains silica (SiO2), alumina (Al2O3), and iron oxide (Fe2O3), with minor amounts of calcium oxide (CaO), which influence its pozzolanic properties. Ground Granulated Blast Furnace Slag (GGBS) consists mainly of calcium oxide (CaO), silica (SiO2), and alumina (Al2O3), offering latent hydraulic characteristics that contribute to enhanced strength and durability in concrete. The higher CaO content in GGBS accelerates cement hydration compared to the predominantly siliceous and aluminous composition of fly ash.

Physical Properties Comparison

Fly ash typically exhibits finer particle size and spherical shape, improving workability and reducing water demand in concrete. GGBS particles are angular and coarser, leading to slower hydration but enhanced long-term strength and durability. Both materials contribute to reduced heat of hydration, but GGBS offers superior density and lower permeability in hardened concrete.

Production Processes and Sources

Fly ash is a byproduct of coal combustion in thermal power plants, collected from exhaust gases through electrostatic precipitators or bag filters, consisting mainly of fine particulate matter rich in silica, alumina, and iron oxides. GGBS (Ground Granulated Blast Furnace Slag) is produced by rapidly cooling molten slag--a byproduct of iron smelting in blast furnaces--through water quenching to form a glassy granulate, which is then ground into a fine powder with high calcium content. Both materials are industrial byproducts repurposed as cementitious additives, with fly ash primarily derived from coal combustion and GGBS from iron manufacturing processes.

Applications in Concrete and Construction

Fly ash enhances the workability and durability of concrete, making it ideal for large-scale infrastructure projects like highways, bridges, and dams. GGBS improves strength and resistance to chemical attacks, commonly used in high-performance concrete for marine structures, sewage systems, and sustainable buildings. Both materials contribute to reducing Portland cement usage, lowering carbon emissions in construction.

Environmental Impact and Sustainability

Fly ash and GGBS (Ground Granulated Blast Furnace Slag) both serve as sustainable supplementary cementitious materials that reduce cement clinker demand and lower CO2 emissions in concrete production. Fly ash, a byproduct of coal combustion, helps divert industrial waste from landfills but may raise concerns related to heavy metal content and variability in supply. GGBS, derived from steel manufacturing slag, offers consistent quality, enhances concrete durability, and significantly reduces carbon footprint by utilizing an otherwise industrial byproduct, promoting circular economy principles.

Performance in Durability and Strength

Fly ash enhances concrete durability by improving resistance to sulfate attack, alkali-silica reaction, and reducing permeability due to its pozzolanic properties. GGBS significantly increases compressive strength and long-term durability by forming additional cementitious compounds that refine the microstructure, leading to better resistance against chloride ingress and reduced corrosion of reinforcement. Both materials improve concrete performance, but GGBS often results in higher strength gains and superior durability in aggressive environments.

Cost Implications and Economic Benefits

Fly ash is generally more cost-effective than GGBS due to its widespread availability and lower processing costs, making it an economical choice for large-scale concrete production. GGBS offers enhanced durability and strength, potentially reducing long-term maintenance expenses and lifecycle costs in infrastructure projects. Selecting between fly ash and GGBS involves balancing immediate material costs with anticipated economic benefits tied to performance and sustainability.

Standards and Specifications

Fly ash and GGBS (Ground Granulated Blast Furnace Slag) are both supplementary cementitious materials specified under standards such as ASTM C618 for fly ash and ASTM C989 for GGBS in the United States, ensuring quality and performance in concrete applications. Fly ash is classified primarily into Class F and Class C based on its chemical composition and pozzolanic properties as per ASTM C618, while GGBS is graded by fineness and strength activity index according to ASTM C989. European standards like EN 450 for fly ash and EN 15167 for GGBS provide guidelines focusing on chemical composition, physical properties, and performance criteria, facilitating their use in sustainable and high-performance concrete mixes.

Future Trends in Supplementary Cementitious Materials

Future trends in supplementary cementitious materials emphasize increased adoption of Fly Ash and GGBS due to their environmental benefits and enhanced durability properties. Innovations focus on optimizing the particle size distribution and chemical composition of Fly Ash and GGBS to improve hydration kinetics and long-term strength development in concrete. Research also highlights the integration of these materials within sustainable construction frameworks to reduce carbon emissions and promote circular economy practices in the cement industry.

Pozzolanic activity

Fly ash exhibits moderate pozzolanic activity by reacting with calcium hydroxide to form cementitious compounds, while GGBS demonstrates higher pozzolanic reactivity and contributes superior strength and durability enhancements in concrete mixtures.

Latent hydraulic binder

Fly ash and GGBS both serve as latent hydraulic binders, with GGBS exhibiting faster strength development and higher early reactivity compared to the slower, pozzolanic reaction of fly ash.

Alkali-silica reaction (ASR)

Fly ash and GGBS both mitigate Alkali-Silica Reaction (ASR) in concrete by reducing alkali content and binding available silica, with GGBS typically providing faster strength gain and superior ASR resistance due to its higher calcium content.

Sulfate resistance

Fly ash exhibits moderate sulfate resistance due to its pozzolanic properties, while Ground Granulated Blast Furnace Slag (GGBS) provides superior sulfate resistance by densifying the concrete microstructure and reducing permeability.

Cement replacement material (CRM)

Fly ash and GGBS are widely used cement replacement materials in concrete production, with GGBS offering higher strength and durability enhancement, while fly ash improves workability and reduces carbon footprint.

Calcium silicate hydrate (C-S-H)

Fly ash produces less Calcium silicate hydrate (C-S-H) compared to Ground Granulated Blast Furnace Slag (GGBS), which enhances concrete strength and durability through higher C-S-H formation.

Setting time modification

Fly ash delays initial and final setting times in concrete mixtures, whereas GGBS typically extends setting time more moderately while enhancing long-term strength and durability.

Concrete durability index

GGBS enhances concrete durability index significantly by reducing permeability and increasing resistance to sulfate attack compared to fly ash, making it more effective in aggressive environments.

Fineness modulus

Fly ash typically has a lower fineness modulus ranging from 2.0 to 3.5 compared to Ground Granulated Blast Furnace Slag (GGBS), which usually exhibits a higher fineness modulus of approximately 3.5 to 4.5, affecting the reactivity and strength development in concrete mixtures.

Chloride permeability

Fly ash significantly reduces chloride permeability in concrete by enhancing pore structure refinement, whereas GGBS offers moderate reduction but excels in long-term durability improvements.

Fly ash vs GGBS (Ground Granulated Blast Furnace Slag) Infographic

njnir.com

njnir.com