Slurry walls and diaphragm walls are both underground structural elements used for earth retention and groundwater cutoff in civil engineering projects. Slurry walls are constructed by excavating trenches filled with bentonite slurry to support the trench walls, then replacing the slurry with concrete, whereas diaphragm walls are created using trench cutters to form a reinforced concrete wall directly in the ground. Diaphragm walls typically provide greater strength and impermeability, making them suitable for deeper excavations and more complex construction requirements compared to traditional slurry walls.

Table of Comparison

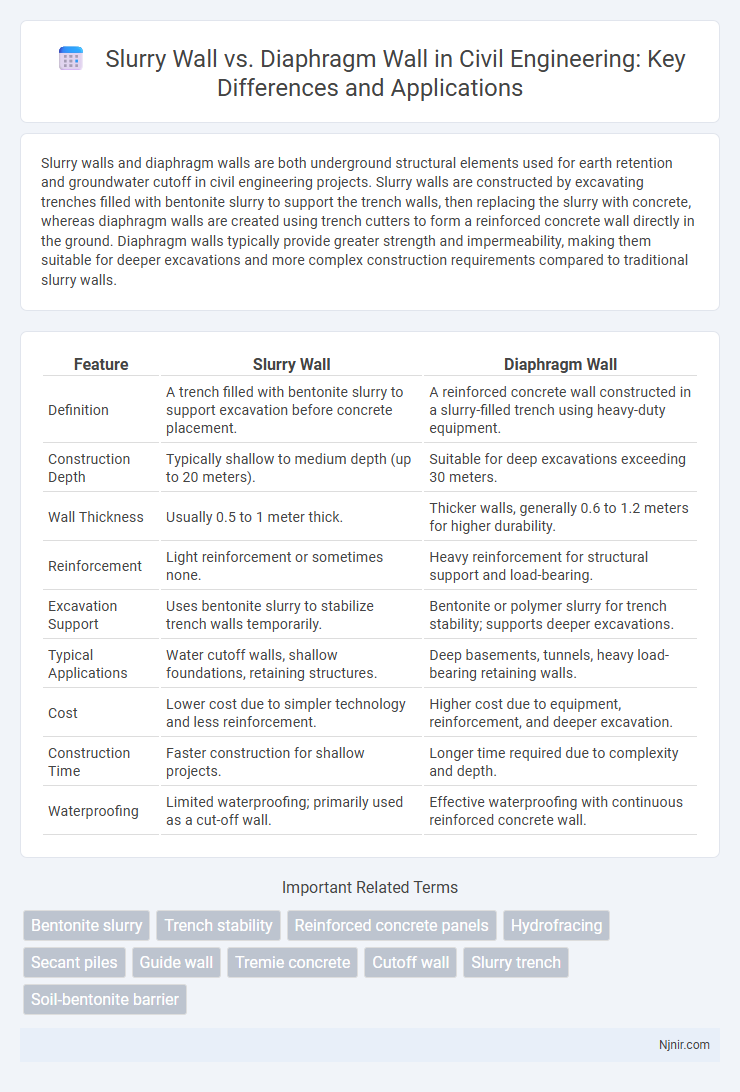

| Feature | Slurry Wall | Diaphragm Wall |

|---|---|---|

| Definition | A trench filled with bentonite slurry to support excavation before concrete placement. | A reinforced concrete wall constructed in a slurry-filled trench using heavy-duty equipment. |

| Construction Depth | Typically shallow to medium depth (up to 20 meters). | Suitable for deep excavations exceeding 30 meters. |

| Wall Thickness | Usually 0.5 to 1 meter thick. | Thicker walls, generally 0.6 to 1.2 meters for higher durability. |

| Reinforcement | Light reinforcement or sometimes none. | Heavy reinforcement for structural support and load-bearing. |

| Excavation Support | Uses bentonite slurry to stabilize trench walls temporarily. | Bentonite or polymer slurry for trench stability; supports deeper excavations. |

| Typical Applications | Water cutoff walls, shallow foundations, retaining structures. | Deep basements, tunnels, heavy load-bearing retaining walls. |

| Cost | Lower cost due to simpler technology and less reinforcement. | Higher cost due to equipment, reinforcement, and deeper excavation. |

| Construction Time | Faster construction for shallow projects. | Longer time required due to complexity and depth. |

| Waterproofing | Limited waterproofing; primarily used as a cut-off wall. | Effective waterproofing with continuous reinforced concrete wall. |

Introduction to Slurry Walls and Diaphragm Walls

Slurry walls and diaphragm walls are critical structural elements used in deep excavation projects to provide earth retention and groundwater control. Slurry walls are constructed by excavating a trench filled with a bentonite slurry that supports the trench walls until concrete is poured, forming a continuous barrier. Diaphragm walls, also known as slurry walls in some regions, involve similar trench excavation techniques but use reinforced concrete panels, offering higher structural strength and durability for complex underground constructions.

Definition and Construction Methods

A slurry wall is a trench excavation filled with a bentonite slurry to support the sides, then backfilled with concrete for underground structures, commonly used in soft soil conditions. Diaphragm walls are reinforced concrete walls constructed by excavating narrow trenches supported by bentonite slurry, followed by placing reinforcement cages and pouring concrete using tremie pipes. Both methods provide structural support and water cut-off but differ in construction complexity and application scale.

Key Materials Used in Both Wall Types

Slurry walls primarily use bentonite slurry to support excavation and prevent soil collapse, combined with reinforced concrete poured after slurry removal to form the structural wall. Diaphragm walls rely on a mixture of bentonite or polymer slurry during excavation, followed by the placement of reinforced concrete or tremie concrete for structural strength. The key difference lies in the slurry composition and the concrete placement method, impacting durability and environmental compatibility.

Structural Differences between Slurry and Diaphragm Walls

Slurry walls consist of a trench filled with bentonite slurry to support excavation, whereas diaphragm walls are constructed using reinforced concrete panels cast in situ within a deep trench. Structurally, slurry walls rely on slurry pressure to maintain trench stability until concrete is poured, while diaphragm walls are inherently load-bearing due to their reinforced concrete framework. Diaphragm walls provide higher structural integrity and water-tightness, making them suitable for deep excavations under challenging ground and water conditions compared to slurry walls.

Applications in Civil Engineering Projects

Slurry walls and diaphragm walls are essential structural elements in civil engineering projects for deep excavation and groundwater control. Slurry walls are commonly used for temporary earth retention in urban construction sites and environmental containment, while diaphragm walls provide permanent, robust retaining structures in large-scale infrastructure such as tunnels, basements, and underground stations. The choice between slurry and diaphragm walls depends on factors like soil conditions, project duration, and structural load requirements, with diaphragm walls offering higher load-bearing capacity and slurry walls favoring flexibility and cost efficiency.

Advantages of Slurry Walls

Slurry walls offer cost-effective construction for deep excavations with excellent groundwater control, making them ideal for urban settings with limited space. Their installation involves a simple trench excavation filled with bentonite slurry, which stabilizes the soil and reduces the risk of collapse. Slurry walls also provide flexibility in design adjustments and faster construction times compared to diaphragm walls, enhancing overall project efficiency.

Benefits of Diaphragm Walls

Diaphragm walls offer superior structural integrity and watertightness compared to slurry walls, making them ideal for deep excavations and urban construction projects. Their precast segments provide enhanced durability and load-bearing capacity, reducing the risk of settlement and groundwater infiltration. This construction technique also allows for greater precision and flexibility in complex geotechnical conditions, ensuring long-term stability and safety.

Comparative Performance: Strength and Durability

Slurry walls and diaphragm walls both offer robust structural support for deep excavations, but diaphragm walls typically provide higher strength and greater durability due to their continuous reinforced concrete construction, which resists deformation and hydrostatic pressure more effectively. Slurry walls rely on bentonite slurry to stabilize trench walls before concrete placement, resulting in slightly lower tensile strength and increased potential for seepage compared to diaphragm walls. In terms of long-term performance, diaphragm walls are preferred in demanding engineering projects requiring superior load-bearing capacity and resistance to aggressive soil and water conditions.

Cost Analysis: Slurry Wall vs Diaphragm Wall

Slurry walls generally offer lower initial construction costs due to simpler excavation and lower material expenses compared to diaphragm walls, which require more specialized equipment and concrete usage. Diaphragm walls provide superior structural strength and water-tightness, leading to reduced long-term maintenance costs in complex geotechnical conditions. Cost analysis favors slurry walls for shallow or less demanding projects, while diaphragm walls are more cost-effective in deep excavations or environments requiring high durability.

Selection Criteria for Optimal Wall Type

Slurry walls are preferred for shallow excavations and soft soil conditions due to their cost-effectiveness and ease of construction, while diaphragm walls are better suited for deep excavations and complex geological environments requiring high structural strength. Selection depends on factors such as soil permeability, groundwater pressure, excavation depth, and project budget constraints. Evaluating site-specific geotechnical data ensures the optimal wall type provides stability, minimizes settlement, and controls groundwater effectively.

Bentonite slurry

Bentonite slurry stabilizes excavation walls in both slurry walls and diaphragm walls by providing hydrostatic pressure to prevent soil collapse during construction.

Trench stability

Diaphragm walls provide superior trench stability compared to slurry walls by utilizing impermeable concrete panels that resist soil and water pressures more effectively during excavation.

Reinforced concrete panels

Reinforced concrete panels in slurry walls provide temporary excavation support with easier installation, while diaphragm walls offer permanent structural stability with thicker, heavily reinforced panels designed for deep foundations.

Hydrofracing

Hydrofracing in slurry walls involves high-pressure water injection to enhance permeability and structural integrity, while diaphragm walls use mechanical excavation and concrete casting without hydrofracing techniques.

Secant piles

Secant piles, combining primary and secondary reinforced concrete elements, offer a flexible alternative to diaphragm walls for constructing slurry walls in challenging soil conditions and tight urban sites.

Guide wall

A guide wall in slurry wall construction serves as a temporary structure to ensure accurate excavation alignment and support, whereas diaphragm walls typically use permanent reinforced concrete guide walls for precise trench shaping and stability.

Tremie concrete

Tremie concrete is essential for both slurry wall and diaphragm wall construction, ensuring stable, continuous underwater concrete placement to prevent contamination and maintain structural integrity.

Cutoff wall

Slurry walls provide effective cutoff barriers in groundwater control by using bentonite slurry for trench stability, while diaphragm walls offer superior structural strength and precision for deep, permanent cutoff wall construction in urban excavation projects.

Slurry trench

Slurry trench walls use bentonite slurry to support trench excavation and are cost-effective for shallow groundwater barriers, while diaphragm walls are reinforced concrete structures suited for deeper and more complex excavations.

Soil-bentonite barrier

Soil-bentonite slurry walls provide a cost-effective, low-permeability barrier primarily for groundwater control, while diaphragm walls offer greater structural strength and depth capabilities for deep excavation support in complex geotechnical conditions.

Slurry wall vs Diaphragm wall Infographic

njnir.com

njnir.com