High-performance concrete (HPC) offers enhanced strength, durability, and workability compared to conventional concrete, making it suitable for various structural applications requiring improved performance under stress and harsh environments. Ultra-high-performance concrete (UHPC) surpasses HPC with exceptional compressive strength, superior durability, and superior resistance to abrasion and chemical attack, achieved through optimized mix design and advanced additives like fibers. The choice between HPC and UHPC depends on project requirements for load-bearing capacity, longevity, and environmental exposure, with UHPC providing unmatched performance for extreme engineering challenges.

Table of Comparison

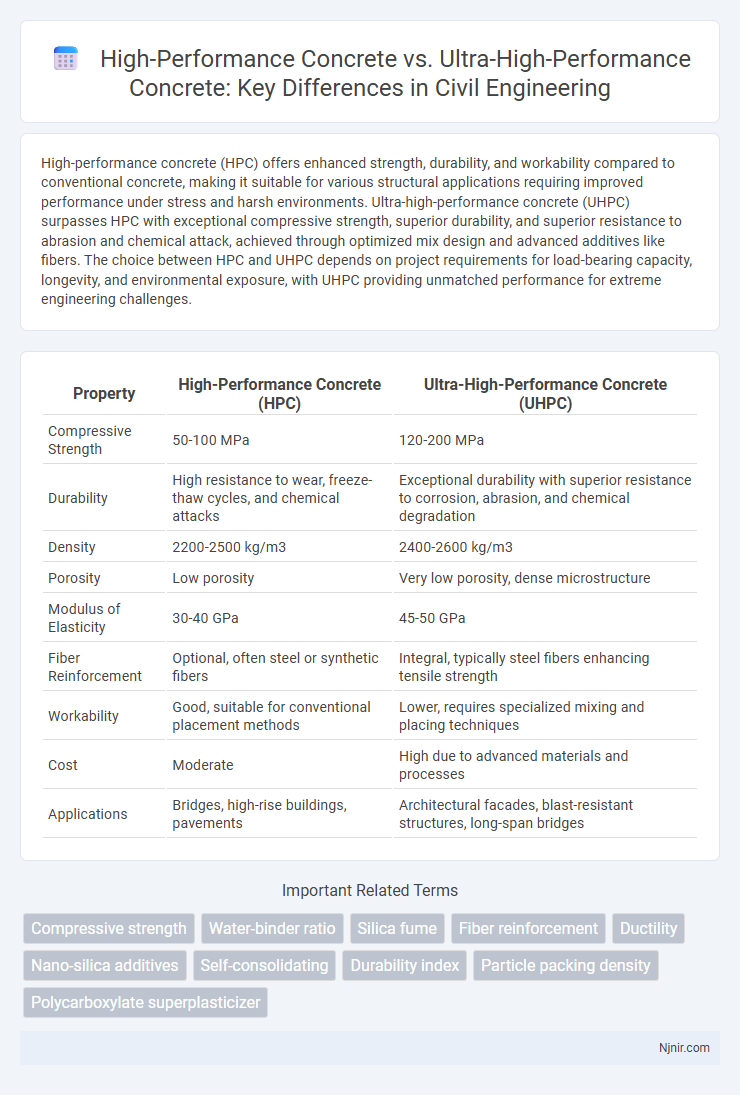

| Property | High-Performance Concrete (HPC) | Ultra-High-Performance Concrete (UHPC) |

|---|---|---|

| Compressive Strength | 50-100 MPa | 120-200 MPa |

| Durability | High resistance to wear, freeze-thaw cycles, and chemical attacks | Exceptional durability with superior resistance to corrosion, abrasion, and chemical degradation |

| Density | 2200-2500 kg/m3 | 2400-2600 kg/m3 |

| Porosity | Low porosity | Very low porosity, dense microstructure |

| Modulus of Elasticity | 30-40 GPa | 45-50 GPa |

| Fiber Reinforcement | Optional, often steel or synthetic fibers | Integral, typically steel fibers enhancing tensile strength |

| Workability | Good, suitable for conventional placement methods | Lower, requires specialized mixing and placing techniques |

| Cost | Moderate | High due to advanced materials and processes |

| Applications | Bridges, high-rise buildings, pavements | Architectural facades, blast-resistant structures, long-span bridges |

Introduction to High-Performance and Ultra-High-Performance Concrete

High-performance concrete (HPC) exhibits enhanced mechanical properties, durability, and workability compared to conventional concrete, achieved through optimized mix designs and advanced admixtures. Ultra-high-performance concrete (UHPC) further advances these characteristics with compressive strengths typically exceeding 150 MPa, incorporating fine powders, fibers, and low water-to-cement ratios for superior density and toughness. The transition from HPC to UHPC marks a shift toward materials engineered for extreme structural demands and extended service life in infrastructure applications.

Defining Properties: HPC vs UHPC

High-performance concrete (HPC) exhibits enhanced strength, durability, and workability compared to conventional concrete, typically achieving compressive strengths between 50 MPa and 100 MPa. Ultra-high-performance concrete (UHPC) surpasses HPC with compressive strengths exceeding 150 MPa, often reaching up to 250 MPa, and features superior ductility, density, and reduced porosity due to optimized particle packing and fiber reinforcement. The defining properties distinguishing UHPC from HPC include its significantly higher tensile strength, exceptional durability under aggressive environmental conditions, and low permeability that extends structural lifespan.

Composition and Material Differences

High-performance concrete (HPC) typically combines Portland cement, fine and coarse aggregates, supplementary cementitious materials (SCMs) like fly ash or silica fume, and superplasticizers, achieving enhanced strength and durability compared to conventional concrete. Ultra-high-performance concrete (UHPC) incorporates a denser matrix with very fine powders such as silica fume, quartz flour, and a high volume of cementitious materials alongside steel fibers and optimized particle packing to achieve compressive strengths exceeding 150 MPa. The key material difference lies in UHPC's lower water-to-cement ratio, higher steel fiber content, and absence of coarse aggregates, resulting in a more homogeneous and ultra-dense composite structure.

Mechanical Strength Comparison

High-performance concrete (HPC) typically achieves compressive strengths ranging from 50 to 100 MPa, while ultra-high-performance concrete (UHPC) can exceed 150 MPa, with some formulations reaching up to 250 MPa. The superior mechanical strength of UHPC results from optimized particle packing, reduced porosity, and the inclusion of steel fibers, enhancing tensile strength and toughness compared to HPC. This increased strength allows UHPC to be used in highly demanding structural applications where durability and load-bearing capacity are critical.

Durability and Longevity

High-performance concrete (HPC) offers enhanced durability through its optimized mix design, resulting in improved resistance to environmental factors such as freeze-thaw cycles, chemical attacks, and abrasion. Ultra-high-performance concrete (UHPC) surpasses HPC by exhibiting exceptional compressive strength, low permeability, and superior microstructure densification, which significantly extends its service life in harsh conditions. The longevity of UHPC structures often exceeds traditional HPC by several decades due to its advanced durability properties and reduced maintenance requirements.

Workability and Placement Techniques

High-performance concrete (HPC) offers enhanced workability compared to conventional concrete, enabling easier placement through conventional methods like pumping and vibration. Ultra-high-performance concrete (UHPC) requires specialized placement techniques due to its low water-to-cement ratio and dense microstructure, often involving self-consolidation and meticulous formwork to prevent segregation. Both materials demand precise mix design adjustments to balance flowability and mechanical properties during construction.

Applications in Modern Construction

High-performance concrete (HPC) is widely utilized in infrastructure projects such as bridges, tunnels, and high-rise buildings due to its enhanced durability and strength compared to conventional concrete. Ultra-high-performance concrete (UHPC) offers superior compressive strength, exceptional durability, and improved resistance to environmental factors, making it ideal for specialized applications like complex architectural designs, precast components, and blast-resistant structures. Both HPC and UHPC contribute to extended service life and reduced maintenance costs in modern construction, with UHPC enabling innovative engineering solutions that demand extreme performance.

Cost Analysis and Economic Impact

High-performance concrete (HPC) generally offers a cost-effective solution with enhanced durability and strength compared to conventional concrete, making it suitable for long-term infrastructure projects by reducing maintenance expenses. Ultra-high-performance concrete (UHPC) demands a significantly higher initial investment due to specialized materials like silica fume and fine steel fibers, but its superior compressive strength and durability can lead to longer service life and lower lifecycle costs in critical structural applications. Economic impact assessments highlight that despite UHPC's upfront cost being 3 to 5 times greater than HPC, the reduction in repair frequency and extended infrastructure lifespan can result in substantial savings for large-scale projects requiring extreme performance characteristics.

Sustainability and Environmental Factors

Ultra-high-performance concrete (UHPC) offers enhanced durability and significantly longer service life compared to high-performance concrete (HPC), reducing the frequency of repairs and associated environmental impacts. UHPC's dense microstructure minimizes permeability, which leads to lower material degradation and less resource consumption over time, contributing to improved sustainability. Despite higher initial embodied energy in UHPC production, its overall life-cycle environmental footprint is often lower due to enhanced longevity and reduced maintenance needs.

Future Trends in Advanced Concrete Technology

High-performance concrete (HPC) and ultra-high-performance concrete (UHPC) are evolving with innovations in nanomaterials and fiber reinforcement to enhance durability and structural efficiency. Future trends include the integration of AI-driven mix design and real-time monitoring systems to optimize performance and sustainability. These advancements aim to reduce carbon footprint while improving mechanical properties, making UHPC increasingly viable for smart infrastructure applications.

Compressive strength

Ultra-high-performance concrete exhibits compressive strength exceeding 150 MPa, significantly outperforming high-performance concrete, which typically ranges between 50 and 100 MPa.

Water-binder ratio

Ultra-high-performance concrete features a significantly lower water-binder ratio, typically below 0.20, compared to high-performance concrete's ratio of around 0.25 to 0.40, resulting in superior strength and durability.

Silica fume

Silica fume significantly enhances the mechanical strength and durability of ultra-high-performance concrete compared to high-performance concrete by refining its microstructure and reducing porosity.

Fiber reinforcement

Ultra-high-performance concrete incorporates significantly higher fiber reinforcement than high-performance concrete, resulting in superior tensile strength, durability, and crack resistance.

Ductility

Ultra-high-performance concrete exhibits significantly greater ductility than high-performance concrete due to its enhanced fiber reinforcement and optimized matrix composition.

Nano-silica additives

Nano-silica additives significantly enhance the mechanical strength and durability of ultra-high-performance concrete compared to high-performance concrete by refining its microstructure and reducing porosity.

Self-consolidating

Ultra-high-performance concrete (UHPC) exhibits superior self-consolidating properties compared to high-performance concrete (HPC), enabling enhanced flowability, reduced segregation, and higher compaction without mechanical vibration.

Durability index

Ultra-high-performance concrete exhibits a significantly higher durability index than high-performance concrete due to its superior density, reduced porosity, and enhanced resistance to chemical attack and freeze-thaw cycles.

Particle packing density

Ultra-high-performance concrete achieves superior strength and durability compared to high-performance concrete due to its optimized particle packing density, which minimizes voids and enhances material compactness.

Polycarboxylate superplasticizer

Polycarboxylate superplasticizers enhance high-performance concrete by improving workability and strength, while their advanced formulations in ultra-high-performance concrete enable superior flowability and increased durability with reduced water content.

high-performance concrete vs ultra-high-performance concrete Infographic

njnir.com

njnir.com