Shotcrete and Gunite are both pneumatically applied concrete techniques, but Shotcrete consists of a ready-mixed concrete sprayed at high velocity, while Gunite involves dry cement and aggregate mixed at the nozzle with water. Shotcrete offers higher control over water content, resulting in better compressive strength and less shrinkage, making it ideal for structural repairs and complex shapes. Gunite, being more flexible with water addition on-site, is often preferred for thin wall applications and projects requiring rapid placement.

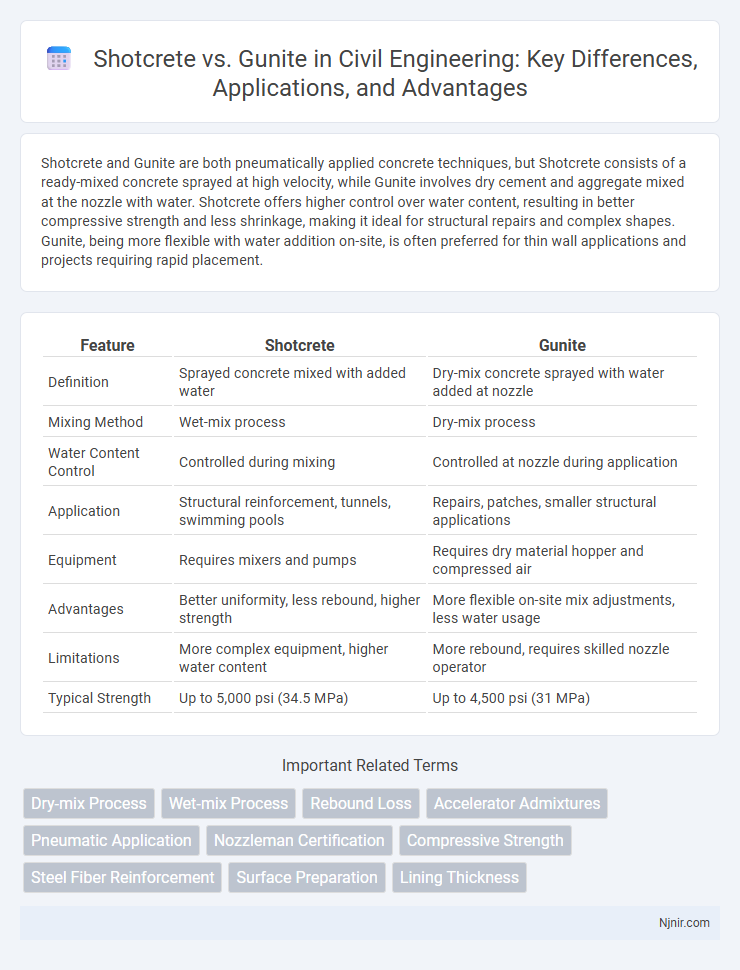

Table of Comparison

| Feature | Shotcrete | Gunite |

|---|---|---|

| Definition | Sprayed concrete mixed with added water | Dry-mix concrete sprayed with water added at nozzle |

| Mixing Method | Wet-mix process | Dry-mix process |

| Water Content Control | Controlled during mixing | Controlled at nozzle during application |

| Application | Structural reinforcement, tunnels, swimming pools | Repairs, patches, smaller structural applications |

| Equipment | Requires mixers and pumps | Requires dry material hopper and compressed air |

| Advantages | Better uniformity, less rebound, higher strength | More flexible on-site mix adjustments, less water usage |

| Limitations | More complex equipment, higher water content | More rebound, requires skilled nozzle operator |

| Typical Strength | Up to 5,000 psi (34.5 MPa) | Up to 4,500 psi (31 MPa) |

Introduction to Shotcrete and Gunite

Shotcrete and gunite are both methods of applying concrete pneumatically, with shotcrete being a wet-mix process where concrete is pre-mixed with water before spraying, and gunite utilizing a dry-mix process where dry cement and aggregates are pneumatically conveyed and mixed with water at the nozzle. Shotcrete offers enhanced control over water content and reduced rebound, making it ideal for structural applications in tunnels, pools, and repairs. Gunite provides greater flexibility for intricate shapes and thinner layers, commonly used in swimming pools and architectural features due to its lower water-cement ratio and ease of application.

Historical Development and Invention

Shotcrete and gunite both originated in the early 20th century, with gunite invented by Carl Akeley in 1907 as a dry-mix process for repairing zoo animal enclosures. Shotcrete, developed shortly after, uses a wet-mix method patented by Taxel and Kaneko in the 1930s, optimizing concrete application through high-velocity spraying. The historical evolution of both methods reflects advancements in construction technology, improving efficiency and structural integrity for applications ranging from tunnel lining to swimming pools.

Key Material Differences

Shotcrete uses a pre-mixed concrete blend with water added at the nozzle, while Gunite is a dry mix of cement and sand with water introduced at the nozzle during application. Shotcrete typically contains additives like accelerators and fibers to enhance strength and durability, whereas Gunite relies on traditional cement and sand proportions without pre-mixed additives. The moisture content and mixing process impact curing time, density, and bonding strength, making Shotcrete generally faster setting and more uniform compared to Gunite.

Application Methods and Equipment

Shotcrete involves pneumatically projecting a pre-mixed or dry mix of concrete through a hose onto a surface using a high-pressure air stream; it requires specialized shotcrete machines equipped with compressors, delivery hoses, and nozzles. Gunite, a dry-mix variant of shotcrete, delivers dry cement and aggregates through a hose while water is added at the nozzle, demanding precise control of water flow and equipment calibrated for dry-mix application. Both methods rely on skilled operators and compatible equipment to ensure uniform application, proper adhesion, and structural integrity in applications such as tunnel linings, swimming pools, and retaining walls.

Strength and Durability Comparison

Shotcrete and Gunite both offer high strength and durability, with Shotcrete typically applied using a wet-mix process that enhances its compressive strength, often reaching 6,000 psi or more. Gunite, utilizing a dry-mix application, provides excellent durability due to its dense, low-permeability matrix, making it resistant to cracking and environmental wear. Both methods ensure long-lasting structural integrity, but Shotcrete's controlled water content generally yields superior strength performance in demanding construction projects.

Cost Analysis: Shotcrete vs Gunite

Shotcrete typically incurs higher material costs due to premixed concrete use, while gunite offers more flexibility with dry mixture pricing, potentially lowering overall expenses. Labor costs for shotcrete tend to be lower because of faster application rates and less rebound waste compared to gunite. Cost-effectiveness ultimately depends on project size and complexity, with gunite favored for smaller jobs and shotcrete preferred for large-scale applications due to economies of scale.

Typical Civil Engineering Uses

Shotcrete and gunite are commonly used in civil engineering for structural repairs, slope stabilization, and tunnel linings, with shotcrete typically applied using a wet-mix process and gunite using a dry-mix process. Shotcrete's efficient placement and high compressive strength make it ideal for large-scale infrastructure projects such as bridges and retaining walls, while gunite's adaptability is preferred for smaller repairs and complex shapes. Both materials provide excellent durability and resistance to environmental stresses, ensuring long-term stability in construction applications.

Advantages of Shotcrete

Shotcrete offers superior compression strength and uniformity compared to Gunite due to its fully machine-mixed process, resulting in denser concrete application with fewer voids. Its adaptability to complex shapes and vertical or overhead surfaces enhances construction efficiency and reduces labor costs. The wet-mix process of Shotcrete minimizes rebound waste and allows for better control of water-to-cement ratios, improving durability and long-term performance in structural and repair applications.

Advantages of Gunite

Gunite offers superior strength and durability due to its dry-mix application, allowing for better control over water content and reducing the risk of shrinkage and cracking. Its versatility makes it ideal for complex shapes and vertical or overhead surfaces, providing excellent adhesion in various construction projects. The fine aggregate in Gunite ensures a smoother finish and enhanced structural integrity compared to Shotcrete.

Selecting the Right Method for Your Project

Shotcrete and gunite are both pneumatically applied concrete methods ideal for structural and decorative applications, but selecting the right one depends on project specifics such as material composition and application technique. Shotcrete uses a wet-mix concrete sprayed at high velocity, offering enhanced strength and faster placement for large-scale projects, while gunite relies on a dry-mix where water is added at the nozzle, providing better control for detailed or repair work. Factors such as project size, complexity, accessibility, and desired finish should guide the decision between shotcrete and gunite to ensure optimal durability and performance.

Dry-mix Process

The dry-mix process in Shotcrete and Gunite involves pneumatically projecting dry cement and aggregate mixture through a hose, where water is added at the nozzle to create a high-strength, fast-setting concrete ideal for structural repairs and complex shapes.

Wet-mix Process

Shotcrete's wet-mix process combines water with dry materials before spraying, resulting in better hydration and reduced rebound compared to Gunite's dry-mix method where water is added at the nozzle.

Rebound Loss

Shotcrete typically experiences less rebound loss than Gunite, improving material efficiency and reducing waste during concrete application.

Accelerator Admixtures

Accelerator admixtures in shotcrete increase setting speed and early strength development, while in gunite they enhance adhesion and workability during dry-mix spraying applications.

Pneumatic Application

Shotcrete and gunite both utilize pneumatic application methods for spraying concrete, with shotcrete typically referring to pre-mixed concrete and gunite involving dry-mix sprayed by compressed air.

Nozzleman Certification

Nozzleman Certification for shotcrete and gunite ensures professionals master spray application techniques, safety standards, and material quality to achieve optimal concrete adhesion and structural integrity.

Compressive Strength

Shotcrete typically achieves higher compressive strength than Gunite due to its wet-mix application allowing better material consistency and compaction.

Steel Fiber Reinforcement

Steel fiber reinforcement in shotcrete provides enhanced tensile strength and crack resistance compared to traditional gunite methods, improving overall structural durability.

Surface Preparation

Proper surface preparation for Shotcrete involves thorough cleaning and roughening of the substrate to ensure optimal adhesion, whereas Gunite requires a dampened surface with minimal water pooling to enhance bonding and prevent material washout.

Lining Thickness

Shotcrete typically requires a thicker lining of 4 to 6 inches for structural support compared to Gunite, which is often applied in thinner layers of 2 to 4 inches due to its dry-mix application method.

Shotcrete vs Gunite Infographic

njnir.com

njnir.com