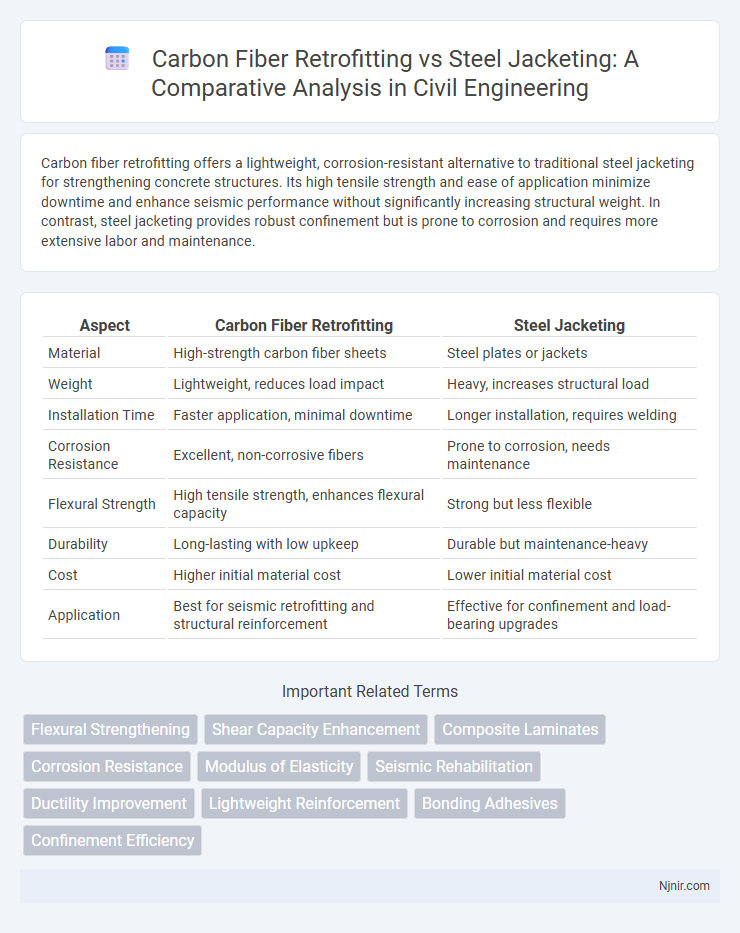

Carbon fiber retrofitting offers a lightweight, corrosion-resistant alternative to traditional steel jacketing for strengthening concrete structures. Its high tensile strength and ease of application minimize downtime and enhance seismic performance without significantly increasing structural weight. In contrast, steel jacketing provides robust confinement but is prone to corrosion and requires more extensive labor and maintenance.

Table of Comparison

| Aspect | Carbon Fiber Retrofitting | Steel Jacketing |

|---|---|---|

| Material | High-strength carbon fiber sheets | Steel plates or jackets |

| Weight | Lightweight, reduces load impact | Heavy, increases structural load |

| Installation Time | Faster application, minimal downtime | Longer installation, requires welding |

| Corrosion Resistance | Excellent, non-corrosive fibers | Prone to corrosion, needs maintenance |

| Flexural Strength | High tensile strength, enhances flexural capacity | Strong but less flexible |

| Durability | Long-lasting with low upkeep | Durable but maintenance-heavy |

| Cost | Higher initial material cost | Lower initial material cost |

| Application | Best for seismic retrofitting and structural reinforcement | Effective for confinement and load-bearing upgrades |

Introduction to Structural Retrofitting in Civil Engineering

Structural retrofitting in civil engineering enhances the load-carrying capacity and seismic resistance of existing buildings. Carbon fiber retrofitting offers high strength-to-weight ratio and corrosion resistance, making it ideal for lightweight and flexible reinforcement. Steel jacketing provides robust confinement and ductility but involves heavier weight and potential corrosion challenges in long-term applications.

Overview of Carbon Fiber Reinforced Polymer (CFRP) Retrofitting

Carbon Fiber Reinforced Polymer (CFRP) retrofitting offers a lightweight, high-strength solution for structural reinforcement, significantly enhancing load-bearing capacity and seismic performance without adding substantial weight or thickness. CFRP materials exhibit excellent corrosion resistance and fatigue durability compared to traditional steel jacketing, making them ideal for long-term infrastructure maintenance. The installation process for CFRP involves bonding carbon fiber sheets or laminates to structural elements, providing tailored reinforcement that improves flexural, shear, and confinement capabilities efficiently.

Fundamentals of Steel Jacketing Techniques

Steel jacketing techniques involve encasing structural elements, typically columns, with steel plates or jackets to enhance load-bearing capacity and seismic resistance. The process requires surface preparation, application of steel jackets with bolts or welding, and often grouting to ensure composite action between steel and concrete. This method improves ductility and confinement, making it effective for retrofitting aging infrastructure compared to carbon fiber retrofitting, which relies on adhesion and lamination of composite materials.

Comparative Analysis: Strength and Load-Bearing Capacity

Carbon fiber retrofitting offers superior tensile strength with a high strength-to-weight ratio, making it ideal for enhancing structural load-bearing capacity without significantly increasing weight. Steel jacketing provides excellent compressive strength and robustness but adds considerable weight and may require more invasive installation. Comparative analysis shows carbon fiber excels in flexibility and corrosion resistance, while steel jacketing remains effective in heavy load scenarios with established durability.

Durability and Corrosion Resistance: CFRP vs Steel

Carbon fiber retrofitting offers superior durability and corrosion resistance compared to steel jacketing due to its non-metallic composition, which resists rust and environmental degradation. CFRP materials maintain structural integrity longer in harsh conditions, reducing maintenance needs and extending service life. Steel jacketing, while strong, is prone to corrosion without protective coatings, leading to potential weakening and costly repairs over time.

Installation Process and Construction Time

Carbon fiber retrofitting involves applying lightweight composite sheets directly onto structural elements, enabling faster installation with minimal disruption compared to steel jacketing, which requires assembling heavy steel plates and securing them with bolts or welding. The construction time for carbon fiber retrofitting is significantly shorter due to its ease of handling and adhesive curing processes, often completed within a few days. Steel jacketing demands extensive preparation, including surface cleaning and alignment, leading to longer installation periods and increased labor costs.

Cost Analysis of Carbon Fiber vs Steel Jacketing

Carbon fiber retrofitting offers a higher initial material cost compared to steel jacketing but significantly reduces labor expenses due to easier installation and lighter weight. Steel jacketing requires extensive preparation and welding, leading to longer project timelines and increased labor costs, which often outweigh the lower material price. Lifecycle cost analysis favors carbon fiber for its corrosion resistance and minimal maintenance, resulting in better long-term economic value despite higher upfront investment.

Impact on Structural Weight and Design Flexibility

Carbon fiber retrofitting significantly reduces structural weight due to its high strength-to-weight ratio compared to steel jacketing, which adds considerable mass to the structure. The lightweight nature of carbon fiber allows for enhanced design flexibility, enabling easier application to complex geometries and minimizing alterations to existing architectural features. Steel jacketing often requires bulkier installations that can limit design options and increase overall structural load.

Long-Term Maintenance and Lifecycle Performance

Carbon fiber retrofitting offers superior long-term maintenance benefits compared to steel jacketing due to its resistance to corrosion and minimal upkeep requirements, resulting in extended structural lifespan. Unlike steel jacketing, which is prone to rust and requires frequent inspections and repairs, carbon fiber provides durable reinforcement with consistent performance over time. Lifecycle performance analysis indicates carbon fiber retrofitting reduces overall maintenance costs and enhances structural resilience in harsh environmental conditions.

Case Studies and Applications in Real-World Projects

Case studies demonstrate carbon fiber retrofitting offers superior strength-to-weight ratio and corrosion resistance compared to steel jacketing, particularly in seismic retrofits of bridges and high-rise buildings. Real-world applications reveal carbon fiber effectively restores structural integrity with minimal added weight, enabling faster installation and reduced downtime. Steel jacketing remains prevalent in older infrastructure projects due to cost-effectiveness but often involves increased load on the foundation and longer labor times.

Flexural Strengthening

Carbon fiber retrofitting provides superior flexural strengthening compared to steel jacketing by offering higher tensile strength, corrosion resistance, and reduced weight, enhancing structural performance and durability.

Shear Capacity Enhancement

Carbon fiber retrofitting increases shear capacity by up to 60% with lightweight, corrosion-resistant properties, while steel jacketing offers 40-50% enhancement but involves heavier weight and corrosion risks.

Composite Laminates

Composite laminate retrofitting with carbon fiber offers superior strength-to-weight ratio and corrosion resistance compared to traditional steel jacketing for structural reinforcement.

Corrosion Resistance

Carbon fiber retrofitting offers superior corrosion resistance compared to steel jacketing, making it more durable in harsh environmental conditions.

Modulus of Elasticity

Carbon fiber retrofitting offers a higher modulus of elasticity compared to steel jacketing, resulting in greater stiffness and improved structural performance.

Seismic Rehabilitation

Carbon fiber retrofitting enhances seismic rehabilitation by providing superior strength-to-weight ratio and corrosion resistance compared to traditional steel jacketing, resulting in improved structural performance and reduced retrofit time.

Ductility Improvement

Carbon fiber retrofitting significantly improves ductility in structural elements by providing high tensile strength and flexibility compared to steel jacketing, which offers increased stiffness but limited ductility enhancement.

Lightweight Reinforcement

Carbon fiber retrofitting provides lightweight reinforcement with high tensile strength, offering superior corrosion resistance and ease of installation compared to heavier, bulkier steel jacketing.

Bonding Adhesives

Carbon fiber retrofitting uses high-strength epoxy bonding adhesives that provide superior adhesion and corrosion resistance compared to the cementitious bonding agents used in steel jacketing.

Confinement Efficiency

Carbon fiber retrofitting provides superior confinement efficiency compared to steel jacketing due to its high tensile strength, corrosion resistance, and ability to evenly distribute stress around structural elements.

carbon fiber retrofitting vs steel jacketing Infographic

njnir.com

njnir.com