3D printed structures offer unparalleled design flexibility and rapid on-site fabrication, reducing construction waste and labor costs compared to traditional precast elements. Precast elements provide proven durability and quality control through factory manufacturing but often require complex logistics and longer lead times for transportation and installation. Combining both methods can optimize structural integrity, speed, and sustainability in modern civil engineering projects.

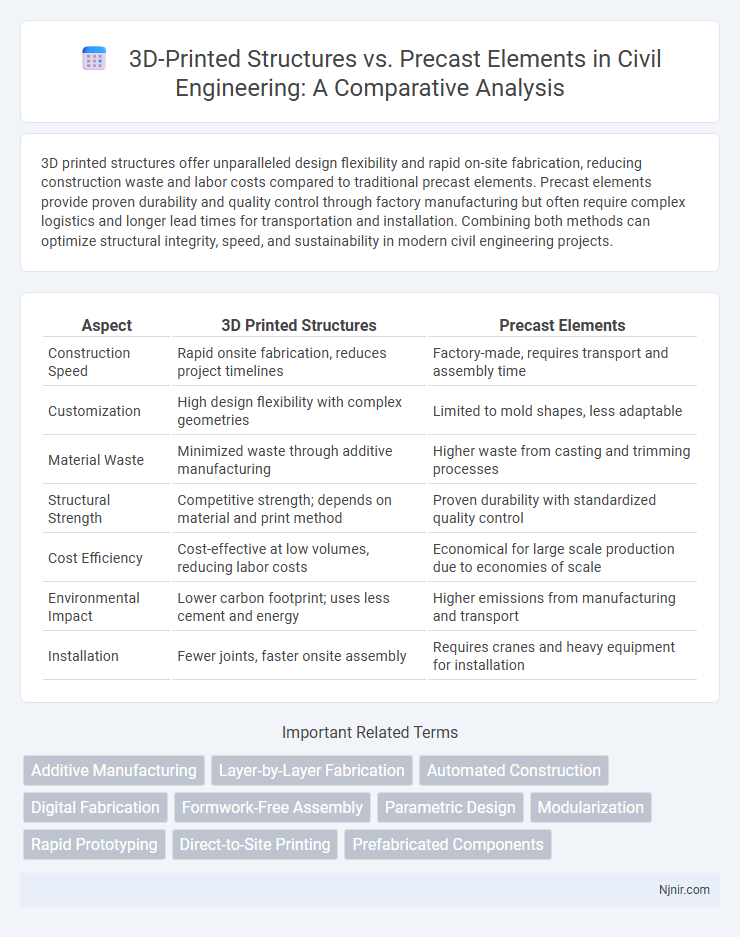

Table of Comparison

| Aspect | 3D Printed Structures | Precast Elements |

|---|---|---|

| Construction Speed | Rapid onsite fabrication, reduces project timelines | Factory-made, requires transport and assembly time |

| Customization | High design flexibility with complex geometries | Limited to mold shapes, less adaptable |

| Material Waste | Minimized waste through additive manufacturing | Higher waste from casting and trimming processes |

| Structural Strength | Competitive strength; depends on material and print method | Proven durability with standardized quality control |

| Cost Efficiency | Cost-effective at low volumes, reducing labor costs | Economical for large scale production due to economies of scale |

| Environmental Impact | Lower carbon footprint; uses less cement and energy | Higher emissions from manufacturing and transport |

| Installation | Fewer joints, faster onsite assembly | Requires cranes and heavy equipment for installation |

Introduction to 3D Printed Structures and Precast Elements

3D printed structures utilize additive manufacturing techniques to create complex architectural forms layer by layer using materials such as concrete, polymers, or composites, offering design flexibility and rapid construction. Precast elements are factory-produced building components, typically made from concrete, cast in molds and transported to the site for assembly, ensuring quality control and consistency. Both methods revolutionize construction by reducing labor costs and material waste, with 3D printing excelling in customization and precast elements in standardized mass production.

Material Properties and Strength Comparison

3D printed structures utilize advanced materials like high-performance concrete composites that can be precisely layered to optimize strength and durability, often resulting in anisotropic properties with enhanced tensile strength along print lines. Precast elements are typically manufactured under controlled factory conditions, ensuring consistent material density and homogeneous mechanical properties, which provide reliable compressive strength and proven long-term performance in load-bearing applications. Comparative studies indicate that while precast concrete exhibits superior uniformity and compressive strength, 3D printed structures offer innovative flexibility in complex geometries and potential for material customization to meet specific structural demands.

Construction Speed and Efficiency

3D printed structures significantly reduce construction time by automating the layering process, enabling continuous building without the delays associated with mold setting and curing typically required in precast elements. The precision of 3D printing minimizes material waste and labor costs, enhancing overall efficiency compared to the traditional manufacturing, transportation, and installation phases of precast components. While precast elements offer consistency and quality control in a factory setting, 3D printing excels in on-site adaptability and rapid prototyping, accelerating project timelines and reducing logistical complexities.

Design Flexibility and Customization

3D printed structures offer superior design flexibility by enabling intricate geometries and complex forms that are challenging or impossible with traditional precast elements. Customization is enhanced in 3D printing through layer-by-layer fabrication, allowing rapid adjustments and unique, site-specific designs without the need for costly molds. Precast elements, while efficient for mass production and consistent quality, are limited by mold constraints and standardization, reducing their adaptability for bespoke architectural features.

Cost Analysis and Economic Impact

3D printed structures significantly reduce labor costs and material waste compared to traditional precast elements, streamlining construction processes and shortening project timelines. Precast elements often require extensive formwork, transportation, and assembly expenses, while 3D printing offers on-site fabrication, lowering logistics and handling costs. The economic impact of adopting 3D printed construction includes increased affordability for housing projects and enhanced sustainability through resource efficiency, driving long-term savings in infrastructure development.

Sustainability and Environmental Considerations

3D printed structures offer significant sustainability advantages over precast elements by minimizing material waste through precise additive manufacturing and enabling the use of recycled or eco-friendly materials, reducing the overall carbon footprint. Precast elements, while durable and reducing on-site construction time, often involve energy-intensive manufacturing processes and transportation that contribute to higher greenhouse gas emissions. The ability of 3D printing to customize designs on-demand also optimizes resource efficiency and decreases the environmental impact associated with overproduction and excess inventory in traditional precast production.

Quality Control and Consistency

3D printed structures offer precise layer-by-layer fabrication with real-time monitoring systems that enhance quality control by minimizing human error and material waste. Precast elements benefit from controlled factory environments ensuring consistent curing and strength, though variability can occur during transport and installation. Both methods demand rigorous quality assurance protocols, but 3D printing allows for greater customization and adaptability while maintaining structural integrity through automated process controls.

Applications in Modern Civil Engineering

3D printed structures offer unparalleled design flexibility and rapid prototyping capabilities, enabling complex geometries and customized forms that traditional precast elements cannot achieve in modern civil engineering. While precast elements provide proven durability, standardized quality control, and faster on-site assembly for repetitive components like beams and slabs, 3D printing excels in creating bespoke components for intricate architectural features and sustainable construction with reduced material waste. The integration of both methods enhances project efficiency, allowing engineers to leverage 3D printing for innovation and precast technology for mass production in infrastructure developments.

Challenges and Limitations

3D printed structures face challenges such as limited material options, slower production speeds, and size constraints compared to traditional precast elements. Precast elements benefit from established manufacturing processes and uniform quality control but struggle with transportation logistics and on-site assembly limitations. Both methods require addressing structural integrity concerns, especially under dynamic loads and environmental exposure.

Future Trends and Innovations

3D printed structures are revolutionizing construction with innovative materials like carbon fiber composites and bio-based concrete, enabling complex geometries and sustainable building practices that surpass traditional precast elements in customization and efficiency. Future trends highlight the integration of AI-driven design algorithms and on-site robotic assembly to reduce construction time and labor costs, while enhancing structural performance and adaptability. Advancements in multi-material printing and real-time sensor embedding are poised to transform maintenance strategies and lifecycle management, positioning 3D printing as the forefront technology in modern infrastructure development.

Additive Manufacturing

Additive manufacturing in 3D printed structures offers greater design flexibility, reduced material waste, and complex geometries compared to traditional precast elements, enabling faster construction and customized architectural solutions.

Layer-by-Layer Fabrication

Layer-by-layer fabrication in 3D printed structures enables precise geometric complexity and material efficiency unmatched by traditional precast elements.

Automated Construction

3D printed structures enable highly automated construction processes by directly fabricating complex designs on-site, reducing labor costs and material waste compared to traditional precast elements that require off-site manufacturing and manual assembly.

Digital Fabrication

Digital fabrication in 3D printed structures enables complex, customizable designs with reduced material waste and faster construction compared to traditional precast elements.

Formwork-Free Assembly

3D printed structures enable formwork-free assembly by directly depositing material layer-by-layer, reducing construction time and labor compared to traditional precast elements that require costly molds and formwork.

Parametric Design

Parametric design enables 3D printed structures to achieve complex geometries and customized forms impossible for traditional precast elements, enhancing architectural innovation and material efficiency.

Modularization

3D printed structures enable highly customizable modularization with complex geometries and reduced construction time compared to traditional precast elements, which offer standardized, mass-produced modules with proven durability and faster on-site assembly.

Rapid Prototyping

3D printed structures enable rapid prototyping by allowing faster design iterations and complex geometries compared to traditional precast elements.

Direct-to-Site Printing

Direct-to-site 3D printed structures reduce transportation costs and construction time compared to precast elements by enabling on-site fabrication of complex, customized components.

Prefabricated Components

Prefabricated components in 3D printed structures offer enhanced design flexibility, reduced construction time, and material efficiency compared to traditional precast elements.

3D Printed Structures vs Precast Elements Infographic

njnir.com

njnir.com