Cold Recycled Asphalt (CRA) offers environmental benefits by reusing existing pavement materials, reducing the need for new aggregates and lowering energy consumption compared to Hot Mix Asphalt (HMA). While HMA provides superior durability and smoother surface finishes due to its high-temperature processing, CRA is cost-effective and suitable for base or intermediate layers in pavement reconstruction. Selecting between CRA and HMA depends on project requirements, climate conditions, and long-term performance goals.

Table of Comparison

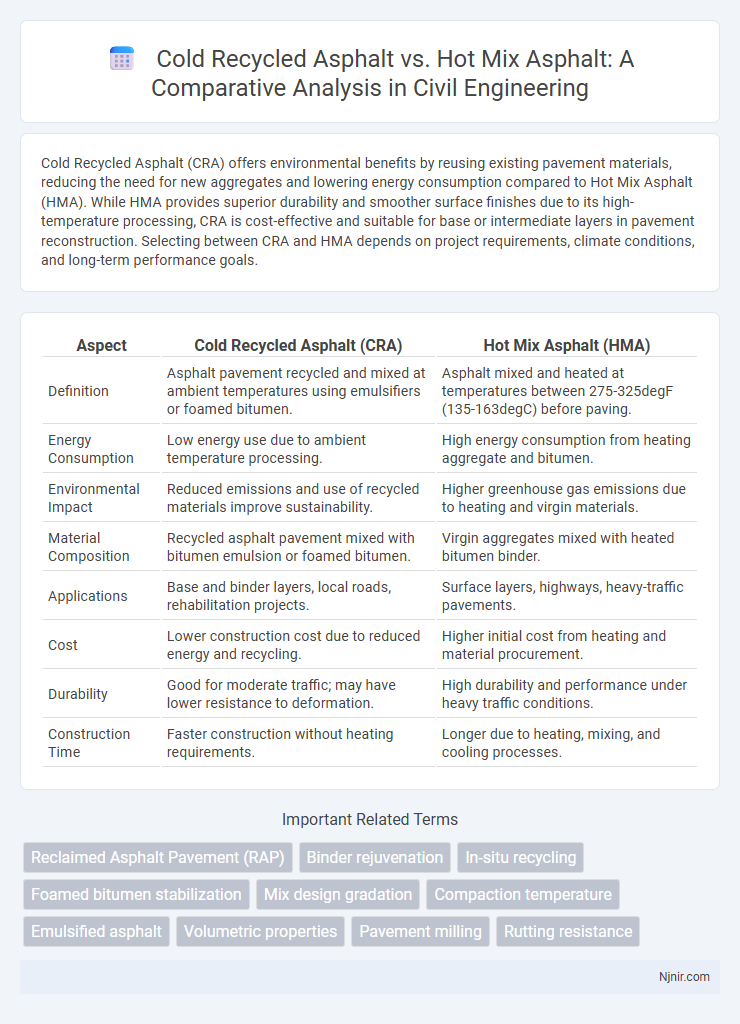

| Aspect | Cold Recycled Asphalt (CRA) | Hot Mix Asphalt (HMA) |

|---|---|---|

| Definition | Asphalt pavement recycled and mixed at ambient temperatures using emulsifiers or foamed bitumen. | Asphalt mixed and heated at temperatures between 275-325degF (135-163degC) before paving. |

| Energy Consumption | Low energy use due to ambient temperature processing. | High energy consumption from heating aggregate and bitumen. |

| Environmental Impact | Reduced emissions and use of recycled materials improve sustainability. | Higher greenhouse gas emissions due to heating and virgin materials. |

| Material Composition | Recycled asphalt pavement mixed with bitumen emulsion or foamed bitumen. | Virgin aggregates mixed with heated bitumen binder. |

| Applications | Base and binder layers, local roads, rehabilitation projects. | Surface layers, highways, heavy-traffic pavements. |

| Cost | Lower construction cost due to reduced energy and recycling. | Higher initial cost from heating and material procurement. |

| Durability | Good for moderate traffic; may have lower resistance to deformation. | High durability and performance under heavy traffic conditions. |

| Construction Time | Faster construction without heating requirements. | Longer due to heating, mixing, and cooling processes. |

Introduction to Asphalt Pavement Technologies

Cold recycled asphalt (CRA) and hot mix asphalt (HMA) represent two critical technologies in asphalt pavement construction and rehabilitation. CRA involves reusing reclaimed asphalt pavement at ambient temperatures, significantly reducing energy consumption and greenhouse gas emissions compared to HMA, which requires heating aggregates and bitumen to high temperatures typically between 275degF and 325degF. Both methods offer distinct advantages in durability, cost-effectiveness, and environmental impact, making them essential options in sustainable pavement engineering.

Overview of Cold Recycled Asphalt

Cold Recycled Asphalt (CRA) is an environmentally friendly pavement rehabilitation method that reuses existing asphalt materials by milling and mixing them with additives at ambient temperature, reducing the need for new aggregates and binder. This technique offers advantages in energy savings, lower emissions, and quicker project completion compared to Hot Mix Asphalt (HMA), which requires heating materials to high temperatures before application. CRA is particularly effective for overlay and base layer applications where cost-efficiency and sustainability are prioritized without compromising pavement performance.

Overview of Hot Mix Asphalt

Hot Mix Asphalt (HMA) consists of aggregate and asphalt binder heated between 275degF and 300degF to produce a pliable mixture for road construction. Known for its durability and strong bonding properties, HMA provides superior load-bearing capacity and resistance to weathering and traffic-induced stresses. It is widely used in highway and urban road applications due to its high-performance characteristics and longevity.

Material Composition and Sourcing

Cold recycled asphalt incorporates reclaimed asphalt pavement (RAP), emulsified asphalt, and additives, reducing reliance on virgin aggregates and bitumen, promoting sustainability through the reuse of existing materials. Hot mix asphalt relies primarily on virgin aggregate and bitumen sourced from quarries and refineries, requiring higher energy inputs during heating and mixing processes. The material composition of cold recycled asphalt allows for lower-temperature processing and less environmental impact, contrasting with the energy-intensive production and sourcing demands of hot mix asphalt.

Construction Methods and Equipment

Cold recycled asphalt involves milling existing pavement and mixing it with rejuvenating agents on-site using specialized cold recycling plants, minimizing the need for high-temperature processes and heavy heating equipment. Hot mix asphalt requires heating aggregates and bitumen to approximately 150-180degC in asphalt plants before transporting to the construction site, where paving machines and rollers compact the mixture. Equipment for cold recycling includes milling machines, recyclers with mixing units, and pavers, while hot mix processes rely heavily on drum or batch plants, asphalt pavers, and heavy rollers for proper compaction.

Environmental Impact Comparison

Cold recycled asphalt significantly reduces energy consumption and greenhouse gas emissions compared to hot mix asphalt by reusing reclaimed materials at lower temperatures, minimizing the need for new raw materials and intensive heating processes. Hot mix asphalt generates higher carbon emissions due to the heating requirements exceeding 300degF during production, contributing more to air pollution and fossil fuel depletion. Cold recycling also lowers landfill waste, promotes sustainable resource management, and decreases volatile organic compound (VOC) emissions, making it a more environmentally friendly pavement rehabilitation method.

Performance and Durability Analysis

Cold recycled asphalt (CRA) exhibits lower initial strength and longer curing times compared to hot mix asphalt (HMA), impacting early performance under load. HMA demonstrates superior durability with enhanced resistance to rutting, cracking, and moisture damage due to higher compaction temperatures and binder quality. Long-term studies show CRA is effective for sustainable pavement rehabilitation but requires careful mix design to achieve performance levels comparable to conventional HMA in heavy traffic conditions.

Cost Efficiency and Lifecycle Assessment

Cold recycled asphalt (CRA) offers significant cost savings by utilizing reclaimed materials and reducing energy consumption during production, leading to lower initial construction expenses compared to hot mix asphalt (HMA). Lifecycle assessments reveal that CRA minimizes environmental impact through decreased greenhouse gas emissions and reduced need for virgin aggregates, enhancing sustainability over HMA's typically higher resource demands. While HMA provides superior durability and performance in high-traffic applications, the cost efficiency and extended lifecycle benefits of CRA make it a practical choice for budget-conscious and eco-friendly pavement projects.

Application Suitability and Limitations

Cold recycled asphalt (CRA) is suitable for low-traffic roads and temporary repairs due to its lower curing temperatures and ease of application, reducing energy consumption and emissions compared to hot mix asphalt (HMA). HMA is ideal for high-traffic, permanent road surfaces, offering superior strength, durability, and resistance to deformation under heavy loads and varying weather conditions. Limitations of CRA include longer curing times and lower initial strength, while HMA requires higher energy input and specialized equipment for mixing and paving.

Future Trends in Asphalt Pavement Solutions

Cold recycled asphalt is gaining traction as a sustainable future trend due to its lower energy consumption and reduced greenhouse gas emissions compared to hot mix asphalt. Innovations in binder technologies and rejuvenators enhance the performance and durability of cold recycled mixtures, promoting their use in high-traffic urban roads. Hot mix asphalt remains essential for heavy-duty applications, but emerging warm-mix additives and recycling methods aim to lower its environmental impact while maintaining superior mechanical properties.

Reclaimed Asphalt Pavement (RAP)

Cold recycled asphalt utilizes higher percentages of Reclaimed Asphalt Pavement (RAP) up to 100%, reducing energy consumption and emissions compared to Hot Mix Asphalt, which typically incorporates 15-30% RAP for enhanced durability and performance.

Binder rejuvenation

Cold recycled asphalt enhances binder rejuvenation by incorporating reclaimed asphalt pavement with rejuvenators to restore binder properties, while hot mix asphalt relies on freshly produced binder with limited rejuvenation effects.

In-situ recycling

In-situ cold recycled asphalt reduces environmental impact and costs by reprocessing existing pavement materials on-site, unlike hot mix asphalt which requires new raw materials and high-temperature production.

Foamed bitumen stabilization

Foamed bitumen stabilization in cold recycled asphalt enhances moisture resistance and structural durability while reducing energy consumption compared to traditional hot mix asphalt.

Mix design gradation

Cold recycled asphalt typically features a coarser and more variable gradation due to reclaimed materials, while hot mix asphalt utilizes a precisely controlled, uniform gradation to optimize performance and durability.

Compaction temperature

Cold Recycled Asphalt is compacted at ambient temperatures typically between 50-90degF, whereas Hot Mix Asphalt requires compaction at elevated temperatures ranging from 275-325degF to ensure proper density and performance.

Emulsified asphalt

Emulsified asphalt in cold recycled asphalt reduces energy consumption and emissions compared to hot mix asphalt, enhancing sustainability while maintaining pavement durability.

Volumetric properties

Cold recycled asphalt exhibits lower density and air void content but higher asphalt binder absorption compared to hot mix asphalt, affecting its volumetric stability and durability.

Pavement milling

Cold recycled asphalt enhances pavement milling efficiency by enabling on-site reuse of milled materials, reducing energy consumption and emissions compared to traditional hot mix asphalt processes.

Rutting resistance

Cold Recycled Asphalt demonstrates lower rutting resistance compared to Hot Mix Asphalt, which offers superior durability and deformation resistance under high traffic loads and elevated temperatures.

Cold Recycled Asphalt vs Hot Mix Asphalt Infographic

njnir.com

njnir.com