Smart sensors provide real-time data with higher accuracy and adaptability compared to traditional monitoring methods in civil engineering. They enable continuous structural health assessment through advanced technologies such as IoT and wireless communication. Traditional monitoring often relies on manual inspections and periodic data collection, leading to potential delays in detecting critical infrastructure issues.

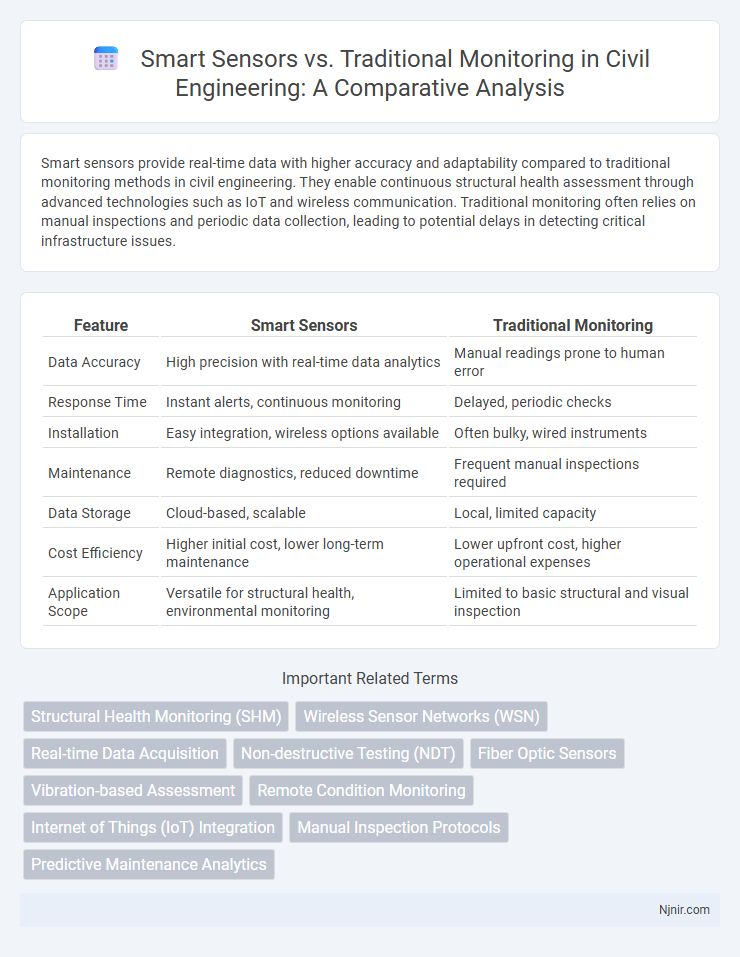

Table of Comparison

| Feature | Smart Sensors | Traditional Monitoring |

|---|---|---|

| Data Accuracy | High precision with real-time data analytics | Manual readings prone to human error |

| Response Time | Instant alerts, continuous monitoring | Delayed, periodic checks |

| Installation | Easy integration, wireless options available | Often bulky, wired instruments |

| Maintenance | Remote diagnostics, reduced downtime | Frequent manual inspections required |

| Data Storage | Cloud-based, scalable | Local, limited capacity |

| Cost Efficiency | Higher initial cost, lower long-term maintenance | Lower upfront cost, higher operational expenses |

| Application Scope | Versatile for structural health, environmental monitoring | Limited to basic structural and visual inspection |

Introduction to Structural Health Monitoring

Smart sensors revolutionize structural health monitoring by providing real-time, continuous data collection, improving accuracy in detecting structural faults compared to traditional monitoring methods that rely on periodic manual inspections. These advanced sensors use technologies such as fiber optics, accelerometers, and strain gauges to capture detailed information on stress, vibration, and deformation. Enhanced data analytics and wireless communication enable proactive maintenance and early warning systems, significantly extending the lifespan and safety of infrastructure.

Overview of Smart Sensor Technologies

Smart sensor technologies integrate advanced microelectromechanical systems (MEMS), Internet of Things (IoT) connectivity, and machine learning algorithms to provide real-time, precise data monitoring and analysis. These sensors offer enhanced capabilities such as self-calibration, adaptive sensing, and wireless communication, significantly improving accuracy and response time compared to traditional monitoring systems. Their use in industries like healthcare, manufacturing, and environmental monitoring enables proactive maintenance, energy efficiency, and improved safety outcomes.

Traditional Monitoring Methods in Civil Engineering

Traditional monitoring methods in civil engineering rely on manual inspections, visual assessments, and mechanical devices such as strain gauges and displacement sensors to evaluate structural health. These techniques, while foundational, often suffer from limitations including lower accuracy, time-consuming data collection, and delayed detection of potential issues. Despite their drawbacks, traditional methods remain essential for initial assessments and provide baseline data critical for comparison with advanced monitoring technologies.

Key Differences: Smart Sensors vs Traditional Monitoring

Smart sensors provide real-time data collection and analysis with higher accuracy and remote monitoring capabilities, unlike traditional monitoring systems that rely on manual data gathering and periodic inspections. These advanced sensors integrate IoT technology, enabling predictive maintenance and automated alerts, which traditional methods lack. Smart sensors also reduce human error and operational costs, offering scalable solutions adaptable to various industries compared to conventional monitoring setups.

Accuracy and Real-Time Data Acquisition

Smart sensors provide significantly higher accuracy through advanced signal processing and self-calibration features, contrasting with traditional monitoring systems that often rely on periodic manual readings prone to human error. Real-time data acquisition in smart sensors enables continuous monitoring and instant anomaly detection, offering immediate insights that traditional methods, dependent on batch data collection, cannot match. This enhanced precision and immediacy improve decision-making in applications ranging from industrial automation to environmental monitoring.

Installation and Maintenance Considerations

Smart sensors feature wireless connectivity and plug-and-play installation, significantly reducing setup time and minimizing reliance on extensive cabling compared to traditional monitoring systems. Their self-diagnostic capabilities enable predictive maintenance, lowering downtime and maintenance costs compared to manual checks required by conventional sensors. Integration with IoT platforms allows real-time monitoring and remote updates, optimizing operational efficiency beyond the capabilities of traditional systems.

Cost Implications and Life-Cycle Analysis

Smart sensors reduce long-term costs by enabling predictive maintenance, minimizing downtime, and optimizing resource use, whereas traditional monitoring often incurs higher expenses due to reactive repairs and frequent manual inspections. Life-cycle analysis shows smart sensors have a higher initial investment but deliver greater return on investment through extended equipment lifespan and improved operational efficiency. Cost implications favor smart sensor adoption in industries prioritizing sustainability and total cost of ownership over short-term expenditure.

Data Management and Analytics Capabilities

Smart sensors offer advanced data management and real-time analytics capabilities, enabling continuous monitoring and instant anomaly detection through integrated IoT platforms. Traditional monitoring systems rely on manual data collection and periodic analysis, resulting in delayed insights and limited data resolution. Enhanced processing power and cloud connectivity of smart sensors facilitate predictive maintenance and optimized operational efficiency, outperforming legacy methods.

Case Studies: Field Applications and Performance

Smart sensors in field applications demonstrate superior accuracy and real-time data collection compared to traditional monitoring, leading to improved decision-making and operational efficiency. Case studies highlight that smart sensors enable predictive maintenance by continuously analyzing environmental and equipment conditions, reducing downtime and costs. Performance metrics from industries like agriculture, manufacturing, and energy consistently show higher data reliability and faster response times with smart sensor deployment over conventional methods.

Future Trends and Recommendations

Smart sensors are revolutionizing monitoring systems by providing real-time data analytics, enhanced accuracy, and predictive maintenance capabilities compared to traditional monitoring methods reliant on manual data collection and periodic checks. Future trends indicate widespread integration of IoT-enabled smart sensors, edge computing, and AI-driven anomaly detection for proactive system management across industries. Organizations should invest in scalable smart sensor networks and continuous software updates to leverage data insights, improve operational efficiency, and reduce downtime.

Structural Health Monitoring (SHM)

Smart sensors enhance Structural Health Monitoring (SHM) by providing real-time data, higher sensitivity, and automated damage detection compared to traditional monitoring methods relying on manual inspections and discrete measurements.

Wireless Sensor Networks (WSN)

Wireless Sensor Networks (WSNs) in smart sensors offer real-time, scalable, and energy-efficient monitoring with enhanced data accuracy compared to traditional wired monitoring systems.

Real-time Data Acquisition

Smart sensors enable real-time data acquisition with high precision and immediate processing, surpassing traditional monitoring systems that rely on delayed and less accurate data collection methods.

Non-destructive Testing (NDT)

Smart sensors enhance Non-destructive Testing (NDT) by providing real-time data analysis, higher sensitivity, and automated defect detection compared to traditional monitoring methods.

Fiber Optic Sensors

Fiber optic sensors in smart monitoring offer higher sensitivity, real-time data transmission, and immunity to electromagnetic interference compared to traditional monitoring systems.

Vibration-based Assessment

Smart sensors enable real-time, high-precision vibration-based assessment with advanced data analytics, surpassing traditional monitoring methods that rely on periodic manual inspections and limited data resolution.

Remote Condition Monitoring

Smart sensors enable real-time remote condition monitoring with higher accuracy and predictive analytics compared to traditional monitoring methods relying on manual data collection.

Internet of Things (IoT) Integration

Smart sensors enable seamless Internet of Things (IoT) integration by providing real-time data collection and advanced analytics, surpassing traditional monitoring systems in efficiency and accuracy.

Manual Inspection Protocols

Smart sensors automate data collection and analysis, significantly reducing errors and time compared to labor-intensive manual inspection protocols used in traditional monitoring.

Predictive Maintenance Analytics

Smart sensors enhance predictive maintenance analytics by providing real-time, high-precision data that enables early fault detection and reduces downtime compared to traditional monitoring methods.

Smart sensors vs Traditional monitoring Infographic

njnir.com

njnir.com