Post-tensioned slabs offer greater design flexibility and reduced cracking compared to pre-tensioned slabs due to on-site tensioning of steel tendons after concrete casting. Pre-tensioned slabs are manufactured with tendons tensioned prior to concrete placement, providing high early strength but limited span length and adaptability. Both methods improve load-bearing capacity, but post-tensioned slabs excel in longer spans and complex structural requirements.

Table of Comparison

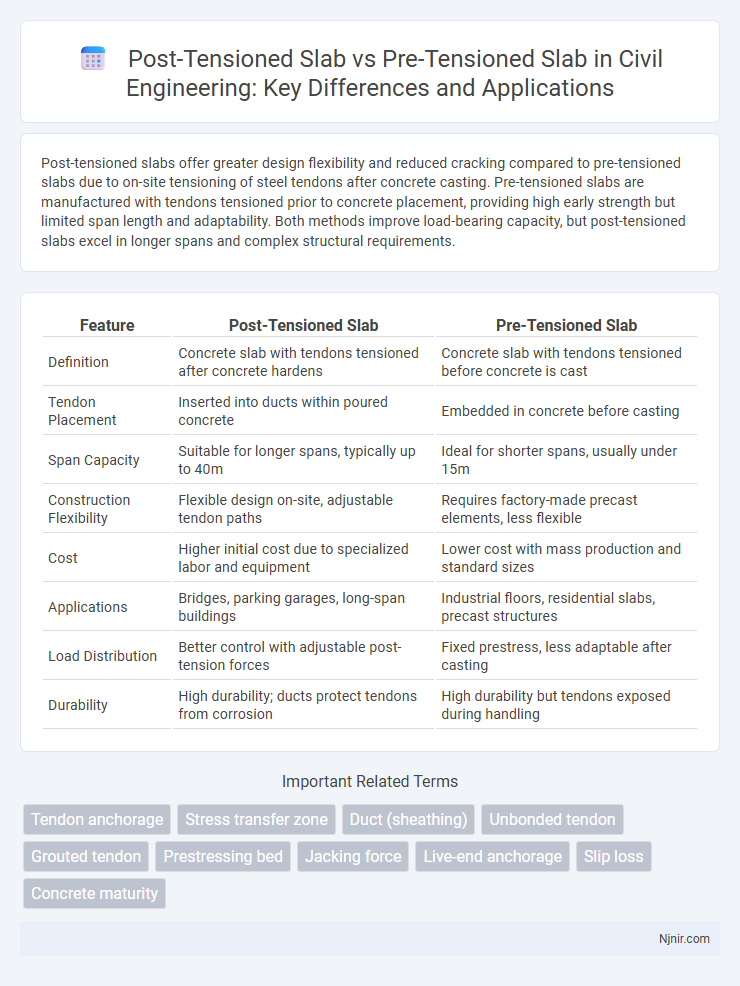

| Feature | Post-Tensioned Slab | Pre-Tensioned Slab |

|---|---|---|

| Definition | Concrete slab with tendons tensioned after concrete hardens | Concrete slab with tendons tensioned before concrete is cast |

| Tendon Placement | Inserted into ducts within poured concrete | Embedded in concrete before casting |

| Span Capacity | Suitable for longer spans, typically up to 40m | Ideal for shorter spans, usually under 15m |

| Construction Flexibility | Flexible design on-site, adjustable tendon paths | Requires factory-made precast elements, less flexible |

| Cost | Higher initial cost due to specialized labor and equipment | Lower cost with mass production and standard sizes |

| Applications | Bridges, parking garages, long-span buildings | Industrial floors, residential slabs, precast structures |

| Load Distribution | Better control with adjustable post-tension forces | Fixed prestress, less adaptable after casting |

| Durability | High durability; ducts protect tendons from corrosion | High durability but tendons exposed during handling |

Introduction to Post-Tensioned and Pre-Tensioned Slabs

Post-tensioned slabs utilize high-strength steel tendons tensioned after concrete placement, offering enhanced load-bearing capacity and reduced slab thickness compared to traditional methods. Pre-tensioned slabs involve tensioning steel strands before concrete casting, delivering uniform stress distribution and faster construction times for precast elements. Both methods improve structural performance by controlling crack development and optimizing material efficiency in concrete slab applications.

Fundamentals of Pre-Tensioned Slab Construction

Pre-tensioned slab construction involves casting concrete around steel tendons that are tensioned before the concrete is poured, providing high tensile strength and reducing cracking. This method requires specialized casting beds and precise control of tendon tension to ensure structural integrity and load distribution. Pre-tensioned slabs are commonly used in precast concrete elements like beams and floor panels, enabling faster construction and enhanced durability compared to traditional reinforced concrete slabs.

Basics of Post-Tensioned Slab Technology

Post-tensioned slab technology involves casting concrete around high-strength steel tendons that are tensioned after the concrete has cured, enhancing load-bearing capacity and reducing concrete thickness. This method allows for longer spans and fewer support columns compared to pre-tensioned slabs, which use tendons tensioned before casting. The ability to apply tension post-curing makes post-tensioned slabs ideal for large-scale constructions requiring flexibility in design and reduced structural weight.

Key Differences Between Post-Tensioned and Pre-Tensioned Slabs

Post-tensioned slabs use tendons that are tensioned after concrete has cured, allowing for longer spans and thinner slabs compared to pre-tensioned slabs, where tendons are tensioned before casting the concrete. Post-tensioning provides greater flexibility in slab design, accommodating complex shapes and site conditions, while pre-tensioning is typically performed in factory settings for standardized elements. The key differences lie in tendon installation timing, slab thickness, structural span capabilities, and adaptability to construction environments.

Material and Equipment Requirements

Post-tensioned slabs require high-strength steel tendons, ducts, and hydraulic jacks to tension the cables after concrete pouring, enabling precise stress control and reduced concrete volume. Pre-tensioned slabs use prestressed steel strands tensioned on a casting bed before concrete placement, demanding specialized casting beds and anchorage systems for maintaining strand tension. Equipment for post-tensioning includes grout pumps and stressing equipment, while pre-tensioning relies heavily on tensioning machines integrated into production facilities.

Structural Performance Comparison

Post-tensioned slabs offer enhanced structural performance by allowing greater spans with reduced slab thickness, resulting in minimized deflections and crack widths under service loads. Pre-tensioned slabs provide high-strength concrete and improved durability due to the prestressing steel being tensioned before casting, leading to uniform prestress distribution but with limited span lengths compared to post-tensioned systems. The flexibility of post-tensioned slabs in accommodating complex shapes and load conditions typically results in superior load-bearing capacity and overall structural efficiency.

Application Areas in Civil Engineering Projects

Post-tensioned slabs are widely used in large-span structures such as bridges, parking garages, and high-rise buildings due to their ability to handle greater loads and reduce slab thickness. Pre-tensioned slabs are typically employed in precast concrete elements like beams, planks, and panels for residential and commercial buildings, where repetitive, controlled factory environments enhance quality and speed of production. Civil engineering projects requiring long spans and on-site casting benefit from post-tensioning, while projects focused on modular construction and mass production favor pre-tensioned slabs.

Cost Implications and Construction Time

Post-tensioned slabs generally offer lower construction costs due to reduced material usage and faster installation compared to pre-tensioned slabs, which require more extensive casting and transportation logistics. Construction time is significantly shorter for post-tensioned slabs as on-site tensioning eliminates the need for long curing periods associated with pre-tensioned slab fabrication at precast plants. Cost savings in post-tensioned slabs are amplified in projects with complex geometries or longer spans, where traditional pre-tensioned elements may increase both labor and transportation expenses.

Durability and Maintenance Considerations

Post-tensioned slabs offer superior durability due to their ability to control cracking and reduce deflections, which minimizes long-term maintenance needs. Pre-tensioned slabs, while also durable, may require more frequent inspections and repairs since the prestressing strands are embedded before concreting and can be susceptible to corrosion if protective measures fail. The reduced susceptibility to environmental damage in post-tensioned slabs often results in lower lifecycle maintenance costs compared to pre-tensioned systems.

Conclusion: Choosing the Right Slab System

Selecting between post-tensioned and pre-tensioned slabs depends on project-specific requirements such as span length, load capacity, and site conditions. Post-tensioned slabs offer greater flexibility for longer spans and reduced structural thickness, making them ideal for complex architectures. Pre-tensioned slabs provide cost-effective solutions for repetitive, shorter spans with high early strength demands, optimizing factory-controlled quality.

Tendon anchorage

Post-tensioned slabs use on-site tendon anchorage allowing for longer spans and adjustable tensioning, while pre-tensioned slabs have factory-fixed tendon anchorage limiting length and requiring transportation constraints.

Stress transfer zone

The stress transfer zone in post-tensioned slabs occurs primarily at the anchorage points where tendons are tensioned after casting, while in pre-tensioned slabs, it is located where tendons bond to concrete during casting, affecting load distribution and structural performance.

Duct (sheathing)

Post-tensioned slabs use flexible ducts for grout injection post-tensioning, whereas pre-tensioned slabs have fixed, embedded sheathing ducts installed during casting for tendon placement.

Unbonded tendon

Unbonded tendons in post-tensioned slabs allow for adjustable tensioning and corrosion monitoring, unlike pre-tensioned slabs where tendons are bonded and stress is fixed before concrete placement.

Grouted tendon

Grouted tendons in post-tensioned slabs provide superior corrosion protection and enhanced bond strength compared to the typically ungrouted tendons in pre-tensioned slabs, improving long-term durability and structural performance.

Prestressing bed

A post-tensioned slab uses on-site tendons tensioned after concrete curing, while a pre-tensioned slab relies on prestressed tendons tensioned in a factory-based prestressing bed before concrete casting.

Jacking force

Post-tensioned slabs use higher jacking forces applied on-site to tension tendons after concrete curing, whereas pre-tensioned slabs involve lower jacking forces applied off-site before concrete casting.

Live-end anchorage

Post-tensioned slabs utilize live-end anchorage to allow adjustable tensioning after concrete curing, while pre-tensioned slabs feature fixed-end anchorage with tendons stressed prior to casting.

Slip loss

Post-tensioned slabs experience higher slip loss due to friction and anchorage set during stressing, whereas pre-tensioned slabs have minimal slip loss as tendons are fixed before concreting.

Concrete maturity

Post-tensioned slabs benefit from accelerated concrete maturity due to controlled tensioning after partial curing, enhancing strength gain compared to pre-tensioned slabs where tensioning occurs before concrete placement.

post-tensioned slab vs pre-tensioned slab Infographic

njnir.com

njnir.com