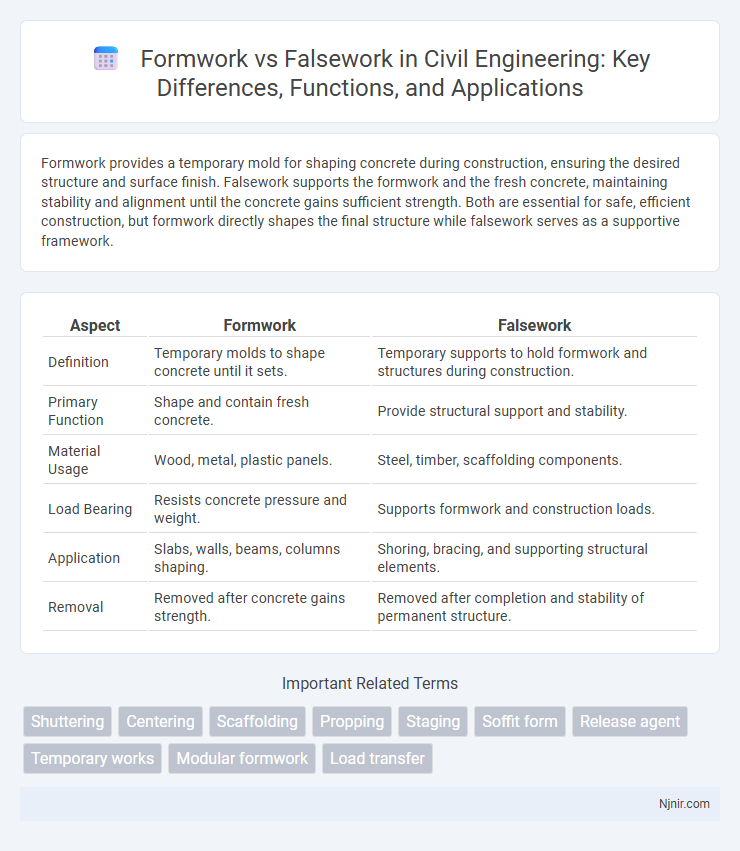

Formwork provides a temporary mold for shaping concrete during construction, ensuring the desired structure and surface finish. Falsework supports the formwork and the fresh concrete, maintaining stability and alignment until the concrete gains sufficient strength. Both are essential for safe, efficient construction, but formwork directly shapes the final structure while falsework serves as a supportive framework.

Table of Comparison

| Aspect | Formwork | Falsework |

|---|---|---|

| Definition | Temporary molds to shape concrete until it sets. | Temporary supports to hold formwork and structures during construction. |

| Primary Function | Shape and contain fresh concrete. | Provide structural support and stability. |

| Material Usage | Wood, metal, plastic panels. | Steel, timber, scaffolding components. |

| Load Bearing | Resists concrete pressure and weight. | Supports formwork and construction loads. |

| Application | Slabs, walls, beams, columns shaping. | Shoring, bracing, and supporting structural elements. |

| Removal | Removed after concrete gains strength. | Removed after completion and stability of permanent structure. |

Introduction to Formwork and Falsework

Formwork refers to temporary molds used to shape and support concrete until it hardens, while falsework provides the structural support system for formwork and construction loads during the building process. Both formwork and falsework are essential in construction for ensuring the concrete maintains its design shape and structural integrity during curing. Efficient design and installation of formwork and falsework reduce construction time and material costs while enhancing safety on site.

Key Differences Between Formwork and Falsework

Formwork serves as a temporary mold to shape and support concrete until it hardens, while falsework provides temporary structural support to hold formwork and construction loads during the building process. Formwork is primarily concerned with the shape and surface finish of concrete, whereas falsework focuses on stability and load-bearing capacity. The key difference lies in their functions: formwork shapes and contains concrete, falsework supports both the formwork and construction elements above.

Functions and Purposes in Construction

Formwork provides the temporary mold that shapes and supports freshly poured concrete until it hardens and attains sufficient strength, ensuring accurate dimensions and surface finish. Falsework serves as the temporary structural support system that holds formwork, loads, and workers during construction, especially in bridges and large-scale projects, maintaining stability and alignment. Both are critical for safe construction practices, with formwork defining the final structure's shape and falsework ensuring overall stability throughout the process.

Materials Used for Formwork and Falsework

Formwork typically utilizes materials like plywood, timber, steel, aluminum, and plastic, selected for their ability to shape concrete accurately and withstand pressure during curing. Falsework primarily consists of steel and timber components designed to support formwork and loads temporarily until the concrete gains sufficient strength. Both systems emphasize durability and strength, but formwork materials prioritize shaping and smooth surface finishes, while falsework materials focus on structural support.

Design Considerations and Standards

Formwork design requires careful selection of materials and load-bearing capacity to ensure proper shaping and support of concrete during curing, adhering to standards such as ACI 347 and BS EN 13670. Falsework design focuses on structural stability and strength to support formwork and fresh concrete loads, guided by codes like AISC and Eurocode 3 for temporary steel structures. Both require precise load calculations, safety factors, and compliance with local building regulations to prevent structural failure and ensure worker safety.

Installation and Assembly Procedures

Formwork installation involves placing molds or panels to shape and support poured concrete until it hardens, requiring precise alignment and secure fastening to withstand concrete pressure. Falsework assembly entails constructing temporary supporting frameworks beneath formwork to bear loads during construction, often using adjustable steel or timber props for stability and load distribution. Both procedures demand careful planning, skilled labor, and adherence to safety standards to ensure structural integrity and efficient workflow.

Safety Measures and Risk Management

Formwork and falsework require stringent safety measures to prevent structural failures during construction. Proper design, regular inspections, and the use of certified materials minimize risks associated with load-bearing and stability. Implementing comprehensive risk management protocols, including worker training and emergency response planning, ensures enhanced safety on site.

Cost Implications and Economic Factors

Formwork and falsework significantly influence construction project costs, with formwork often requiring higher material expenses due to its direct contact with concrete and need for precise shaping. Falsework, primarily used for supporting structures temporarily, incurs costs linked to labor-intensive setup and dismantling processes but can be reused across multiple projects, enhancing economic efficiency. Balancing the initial investment in durable formwork materials against the potential savings from reusable falsework plays a crucial role in optimizing overall budget management in construction engineering.

Innovations and Modern Practices

Innovations in formwork include the use of modular systems made from lightweight materials like aluminum and composite plastics, which enhance reusability and reduce labor time. Modern practices in falsework involve advanced load monitoring technology and adjustable supports that improve safety and precision during concrete curing. Both formwork and falsework now leverage Building Information Modeling (BIM) to optimize design accuracy and construction efficiency.

Maintenance, Removal, and Environmental Impact

Formwork requires frequent maintenance to prevent concrete adhesion and ensure structural accuracy, often involving cleaning and repairs after each use. Falsework demands regular inspection and upkeep to maintain load-bearing capacity and worker safety throughout construction phases. Both materials can contribute to environmental impact through waste generation, though reusable metal or plastic formwork and sustainable falsework practices reduce ecological footprints significantly.

Shuttering

Shuttering, a key component of formwork, involves creating temporary molds to shape concrete during construction, differing from falsework which primarily supports structures until they gain sufficient strength.

Centering

Centering is a type of falsework specifically designed to support formwork and the freshly poured concrete until it gains sufficient strength to become self-supporting.

Scaffolding

Scaffolding serves as temporary support for workers and materials during construction, while formwork provides molded structures for concrete placement, both critical but distinct in their roles within falsework systems.

Propping

Propping is a crucial aspect of falsework that provides temporary support to structures during construction, whereas formwork primarily shapes and contains concrete until it sets.

Staging

Staging in formwork provides temporary support for concrete molds during construction, while in falsework, staging is used to support entire structural elements until permanent supports are in place.

Soffit form

Soffit form, a key component of formwork, provides the mold for concrete ceilings or slabs, while falsework serves as temporary support structures during construction.

Release agent

Formwork release agents prevent concrete adhesion to molds, ensuring smooth structure surfaces, while falsework release agents facilitate the easy removal of temporary supports without damaging structural components.

Temporary works

Formwork shapes and supports concrete until it hardens, while falsework provides temporary structural support to formwork and other construction elements during the building process.

Modular formwork

Modular formwork offers a reusable, adaptable, and efficient solution for shaping concrete structures compared to traditional falsework, which primarily supports temporary loads during construction.

Load transfer

Formwork supports and shapes concrete until it cures, while falsework primarily transfers and distributes structural loads to the ground during construction.

formwork vs falsework Infographic

njnir.com

njnir.com