HDPE pipes offer superior flexibility and resistance to corrosion compared to PVC pipes, making them ideal for underground water and gas distribution systems in civil engineering projects. PVC pipes are more rigid, lightweight, and cost-effective, often preferred for short-term or low-pressure applications such as drainage and sewage systems. Both materials have distinct advantages, with HDPE excelling in durability and environmental stress resistance, while PVC provides ease of installation and affordability.

Table of Comparison

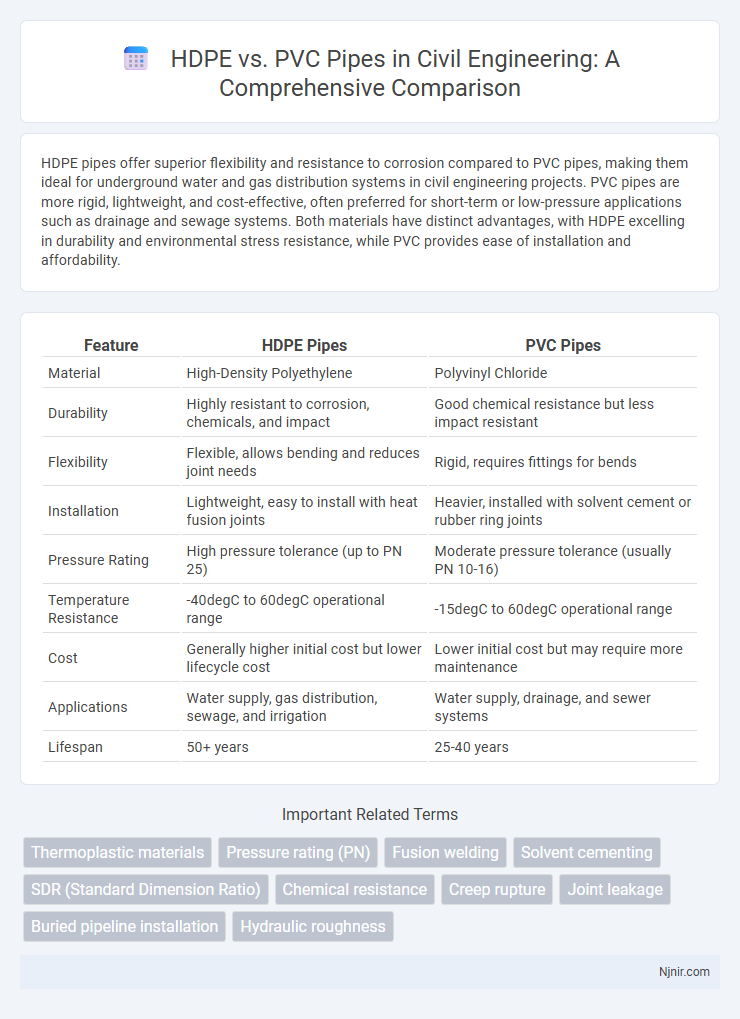

| Feature | HDPE Pipes | PVC Pipes |

|---|---|---|

| Material | High-Density Polyethylene | Polyvinyl Chloride |

| Durability | Highly resistant to corrosion, chemicals, and impact | Good chemical resistance but less impact resistant |

| Flexibility | Flexible, allows bending and reduces joint needs | Rigid, requires fittings for bends |

| Installation | Lightweight, easy to install with heat fusion joints | Heavier, installed with solvent cement or rubber ring joints |

| Pressure Rating | High pressure tolerance (up to PN 25) | Moderate pressure tolerance (usually PN 10-16) |

| Temperature Resistance | -40degC to 60degC operational range | -15degC to 60degC operational range |

| Cost | Generally higher initial cost but lower lifecycle cost | Lower initial cost but may require more maintenance |

| Applications | Water supply, gas distribution, sewage, and irrigation | Water supply, drainage, and sewer systems |

| Lifespan | 50+ years | 25-40 years |

Introduction to HDPE and PVC Pipes

HDPE pipes, made from high-density polyethylene, offer excellent flexibility, chemical resistance, and durability for water supply, gas distribution, and sewage systems. PVC pipes, composed of polyvinyl chloride, provide strong corrosion resistance, low cost, and ease of installation commonly applied in irrigation, drainage, and plumbing. Both materials suit different infrastructure needs based on pressure requirements, environmental conditions, and lifespan expectations.

Material Composition and Properties

HDPE pipes are made from high-density polyethylene, a polymer known for its flexibility, chemical resistance, and durability under high pressure. PVC pipes consist of polyvinyl chloride, characterized by rigidity, excellent corrosion resistance, and ease of installation due to its lightweight nature. Both materials offer distinct advantages: HDPE excels in impact resistance and thermal expansion, while PVC offers superior stiffness and UV resistance in construction applications.

Manufacturing Processes

HDPE pipes are manufactured using extrusion, where high-density polyethylene pellets are melted and formed into continuous pipe sections, providing flexibility and resistance to corrosion. PVC pipes are produced through a polymerization process followed by extrusion or injection molding, resulting in rigid pipes with excellent chemical and weather resistance. The manufacturing differences influence their application suitability, with HDPE favored for underground and industrial use, and PVC commonly used in plumbing and drainage systems.

Strength and Durability Comparison

HDPE pipes exhibit superior flexibility and impact resistance, making them less prone to cracking and breaking under pressure compared to PVC pipes. PVC pipes offer higher rigidity and tensile strength but are more brittle, which can lead to fractures in extreme temperature variations or heavy loads. When assessing long-term durability, HDPE outperforms PVC by resisting corrosion, chemical degradation, and stress cracking, ensuring a longer service life in demanding environments.

Chemical and Corrosion Resistance

HDPE pipes exhibit superior chemical resistance, effectively withstanding acids, alkalis, and salts without degradation, making them ideal for aggressive chemical environments. PVC pipes offer good corrosion resistance but can degrade with exposure to certain solvents and high pH substances over time. Both materials provide durable solutions, yet HDPE's molecular structure gives it enhanced resilience against chemical attack and long-term corrosion compared to PVC.

Installation Methods and Flexibility

HDPE pipes offer superior flexibility due to their high resistance to impact and bending, allowing them to be installed using trenchless methods such as horizontal directional drilling, which reduces surface disruption. PVC pipes, while rigid and easier to handle in straight runs, require more careful jointing and typically rely on traditional open-trench installation, making them less adaptable to complex layouts. The flexibility of HDPE pipes also enables them to accommodate ground movement and thermal expansion better than PVC, minimizing the risk of cracking or joint failure during and after installation.

Cost Analysis and Economic Considerations

HDPE pipes generally offer lower installation and maintenance costs compared to PVC pipes due to their flexibility and durability, reducing expenses related to joint fittings and repairs. PVC pipes have a lower upfront material cost but may incur higher long-term costs from brittleness and susceptibility to cracking under stress. An economic analysis shows HDPE pipes provide better value in infrastructure projects requiring longevity and resistance to environmental factors, despite a slightly higher initial investment.

Environmental Impact and Sustainability

HDPE pipes offer superior environmental benefits due to their recyclability and lower carbon footprint during production compared to PVC pipes, which release harmful dioxins when incinerated or improperly disposed of. HDPE's resistance to corrosion extends pipe lifespan, reducing waste generation and resource consumption over time, while PVC manufacturing relies on chlorine and releases more toxic chemicals. Sustainable infrastructure projects increasingly prefer HDPE pipes for their eco-friendly properties and compliance with green building standards.

Common Applications in Civil Engineering

HDPE pipes are widely used in civil engineering for water supply systems, sewage networks, and gas distribution due to their flexibility, corrosion resistance, and durability. PVC pipes are commonly applied in drainage systems, irrigation, and electrical conduit installations because of their rigidity, ease of installation, and chemical resistance. Both materials serve critical roles in infrastructure projects, with HDPE favored for high-pressure applications and PVC preferred for cost-effective, lightweight piping solutions.

Maintenance, Lifespan, and Performance Evaluation

HDPE pipes require minimal maintenance due to their high resistance to corrosion, chemical damage, and abrasion, making them ideal for long-term use in harsh environments. PVC pipes offer a longer lifespan in non-corrosive conditions but are more susceptible to damage from UV exposure and physical impact, necessitating occasional maintenance. Performance evaluation shows HDPE pipes provide superior flexibility and impact resistance, while PVC pipes excel in cost-effectiveness and rigidity for applications with stable temperature and pressure.

Thermoplastic materials

HDPE pipes offer superior flexibility, chemical resistance, and impact strength compared to PVC pipes, making them more suitable for thermoplastic-based piping systems in harsh environments.

Pressure rating (PN)

HDPE pipes typically offer higher pressure ratings (PN 6 to PN 25) compared to PVC pipes, which usually have pressure ratings ranging from PN 6 to PN 16, making HDPE more suitable for high-pressure applications.

Fusion welding

HDPE pipes offer superior fusion welding durability and flexibility compared to PVC pipes, making them ideal for leak-proof, long-lasting pipeline systems.

Solvent cementing

Solvent cementing creates strong, durable joints in PVC pipes by chemically fusing the material, while HDPE pipes require specialized heat fusion techniques as solvent cementing is ineffective due to their differing polymer structures.

SDR (Standard Dimension Ratio)

HDPE pipes typically feature lower SDR values than PVC pipes, indicating thicker walls relative to their diameter and increased pressure resistance.

Chemical resistance

HDPE pipes exhibit superior chemical resistance to a wide range of acids, bases, and solvents compared to PVC pipes, making them ideal for industrial and corrosive environments.

Creep rupture

HDPE pipes exhibit superior creep rupture resistance compared to PVC pipes, making them more reliable for long-term pressure applications and high-stress environments.

Joint leakage

HDPE pipes exhibit significantly lower joint leakage rates compared to PVC pipes due to their superior fusion welding capabilities and flexible, solvent-free joints.

Buried pipeline installation

HDPE pipes offer superior flexibility, corrosion resistance, and joint integrity compared to PVC pipes, making them the preferred choice for durable and leak-free buried pipeline installations.

Hydraulic roughness

HDPE pipes exhibit lower hydraulic roughness values around 0.007 mm compared to PVC pipes with values typically near 0.01 mm, resulting in reduced friction losses and improved flow efficiency in water transportation systems.

HDPE vs PVC pipes Infographic

njnir.com

njnir.com